Tesla's high-performance aluminum body construction requires specialized repair methods for optimal preservation. Paintless dent repair techniques are commonly used to maintain the vehicle's structural integrity, meticulous finish, and superior design. Skilled technicians follow a meticulous process, combining manual expertise with advanced technologies like CAD and 3D scanning. This ensures that repaired Teslas retain their original shape, strength, and iconic aesthetics, while also preventing long-term issues like corrosion and compromising safety standards.

Tesla’s innovative use of aluminum body construction in their vehicles offers both lightweight benefits and unique challenges during repairs. This article explores how professional Tesla aluminum body repair expertly restores vehicles to their original shape, leveraging specialized techniques tailored to this advanced material. From understanding the distinct characteristics of Tesla’s aluminum bodies to examining the meticulous repair process, we uncover why proper repair is crucial for long-term structural integrity and vehicle value retention.

- Understanding Tesla's Aluminum Body Construction

- The Process of Aluminum Body Repair for Tesla Vehicles

- Benefits and Long-term Impact of Professional Repair

Understanding Tesla's Aluminum Body Construction

Tesla’s use of aluminum in its vehicle construction is a key factor in both the car’s performance and its unique repair process. The brand incorporates high-strength aluminum alloys throughout their vehicles, from the chassis to the body panels. This lightweight yet robust material offers significant advantages over traditional steel, contributing to improved fuel efficiency and handling dynamics. However, it also presents distinct challenges when it comes to repairs, especially in cases of damage like dents or scratches.

When a Tesla requires aluminum body repair, such as after a collision or car damage repair, the goal is to restore the vehicle’s original shape and structural integrity without compromising its performance characteristics. Paintless dent repair techniques are often employed, leveraging specialized tools and expertise to gently press out dents while preserving the original paint finish. This meticulous process ensures that Tesla owners can enjoy their vehicles’ superior design and engineering, even after encountering minor accidents or incidents of car damage repair.

The Process of Aluminum Body Repair for Tesla Vehicles

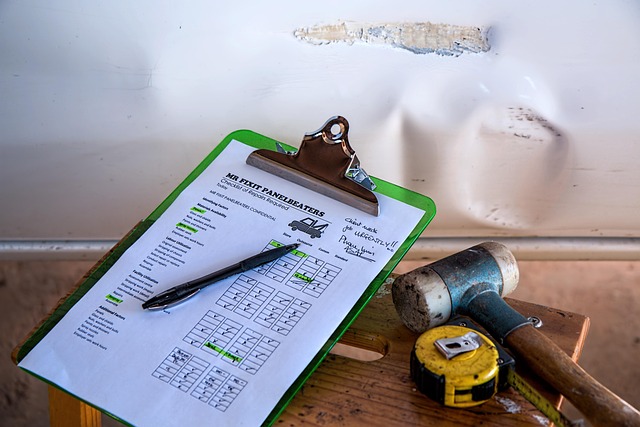

The process of Tesla aluminum body repair involves a meticulous approach to restoring damaged vehicles to their original shape and integrity. It begins with an extensive assessment of the vehicle, identifying areas requiring repair and understanding the extent of the damage. Skilled technicians utilize specialized tools and equipment to carefully remove any dented or damaged panels, ensuring precision and minimal disruption to the car’s structural integrity.

Once removed, the aluminum panels are cleaned and prepared for repair. This meticulous preparation is crucial for achieving a seamless finish. The repair itself involves precise welding techniques, where skilled artisans expertly weld the panels back into place, matching the original contours of the vehicle. Advanced technologies, such as computer-aided design (CAD) and 3D scanning, aid in ensuring accuracy during the repair process, resulting in a restored Tesla that retains its original shape, strength, and sleek aesthetics.

Benefits and Long-term Impact of Professional Repair

Professional Tesla aluminum body repair offers a multitude of benefits that extend far beyond mere aesthetics. By employing skilled technicians and specialized equipment, repairs can restore not just the car’s original shape but also its structural integrity. This is particularly crucial for the lightweight aluminum construction typical in Tesla models, which maintains efficiency and safety standards.

The long-term impact of professional repair is significant, ensuring the vehicle retains its initial design intent and performance capabilities. Unlike DIY or amateur repairs, these services employ high-quality materials that match the original manufacturing standards. This prevents future issues like corrosion, reduced structural strength, and potential safety hazards commonly associated with subpar car body repair, including collision repair and car scratch repair.

Tesla’s innovative use of aluminum in vehicle construction offers both lightweight benefits and unique challenges during repairs. When it comes to restoring a Tesla’s original shape after an accident, professional aluminum body repair techniques are essential. These skilled professionals employ specialized knowledge and tools to precisely mend the intricate panels, ensuring the car not only looks like new but also maintains its structural integrity. Investing in expert Tesla aluminum body repair guarantees long-term performance and preserves the vehicle’s value, making it a crucial step for Tesla owners seeking top-notch repairs.