OEM (Original Equipment Manufacturer) specifications are crucial for auto body fasteners, dictating material, dimensions, finish, and performance to meet vehicle manufacturers' exacting standards. Adhering to these guidelines ensures structural integrity, preserves aesthetic appeal, and prevents future issues in complex repairs like dent repair or paintless dent repair. Correct selection of auto body fasteners—including bolts, screws, nuts, washers, and rivets—is vital for safety and quality, with the right choice maintaining long-lasting performance and preserving the vehicle's original look. Prioritizing OEM specs for auto body fasteners ensures top-notch repairs, customer satisfaction, and peace of mind on the road.

“In the automotive industry, maintaining original equipment manufacturer (OEM) standards is paramount for safety and vehicle performance. This article delves into the critical role of auto body fasteners, exploring how they must adhere to OEM specifications. We’ll dissect the various types of fasteners, their applications, and the strict quality control measures ensuring reliability. By understanding these components, car enthusiasts and professionals can make informed decisions when selecting parts, ultimately enhancing vehicle integrity.”

- Understanding OEM Specifications for Auto Body Fasteners

- Types of Auto Body Fasteners and Their Importance

- Ensuring Quality and Reliability in Auto Body Fastener Selection

Understanding OEM Specifications for Auto Body Fasteners

OEM (Original Equipment Manufacturer) specifications are critical when it comes to auto body fasteners, ensuring they meet the exacting standards set by vehicle manufacturers. These specifications cover a wide range of factors, from material composition and dimensions to finish and performance requirements. Understanding these specifications is paramount for professionals in the auto body repair industry, especially when dealing with complex vehicle dent repair or paintless dent repair procedures.

Auto body fasteners play a pivotal role in maintaining the structural integrity and overall aesthetic appeal of vehicles. When performing auto body repair, adhering to OEM standards guarantees that replacement parts will seamlessly integrate with the existing vehicle, ensuring both safety and visual precision. This is particularly crucial for preserving the vehicle’s original look and preventing any potential issues during future service or paint jobs, making it a key consideration in the realm of auto body fasteners.

Types of Auto Body Fasteners and Their Importance

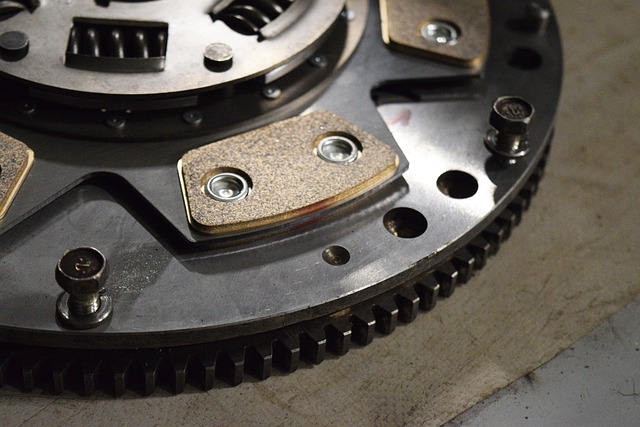

Auto body fasteners play a crucial role in ensuring structural integrity during car body repair and vehicle body repair processes. These components come in various types, each designed for specific applications and offering unique advantages. One common category includes bolts and screws, which are essential for securing panels, frames, and other parts together. Their strength and ability to create a strong bond make them indispensable in auto body fasteners.

Nuts, washers, and rivets also form an integral part of the arsenal. Nuts and washers provide additional support and distribute pressure evenly across joints, preventing loosening over time. Rivets, on the other hand, offer permanent fastening solutions, making them ideal for situations where parts need to be securely attached without the possibility of removal. Proper selection and utilization of these auto body fasteners are vital to match OEM (Original Equipment Manufacturer) specifications, ensuring both safety and quality in dent removal and vehicle body repair procedures.

Ensuring Quality and Reliability in Auto Body Fastener Selection

Choosing the right auto body fasteners is paramount to ensuring the quality and reliability of any auto body services or car damage repair work. When selecting these components, it’s crucial to stick to OEM (Original Equipment Manufacturer) specifications. This guarantees that the fasteners meet the same high standards set by the vehicle manufacturer, promoting long-lasting performance and structural integrity. Opting for auto body fasteners that adhere to these guidelines is vital for preventing future issues like loose parts, rust, and diminished safety during driving.

In the world of auto detailing, the reliability of fasteners can make a significant difference in the final outcome of a repair job. High-quality fasteners not only ensure that repairs hold up over time but also contribute to maintaining the vehicle’s overall aesthetic appeal. By prioritizing auto body fasteners that meet OEM specs, professionals in the field can deliver top-notch auto body services, ensuring customer satisfaction and peace of mind on the road.

When selecting auto body fasteners, adhering to Original Equipment Manufacturer (OEM) specifications is paramount for ensuring safety, durability, and vehicle performance. By understanding these standards and choosing fasteners that meet or exceed them, automotive professionals can guarantee that repairs are as robust as the original equipment, providing long-lasting reliability on the road. Quality auto body fasteners are an investment in both peace of mind and the overall health of a vehicle’s structure.