Structural Safety Verification (SSV) is a rigorous process utilizing advanced technologies like CAD, FEA, and 3D scanning to ensure vehicles maintain long-term structural integrity. Through detailed part analysis, SSV predicts and prevents failures, preserves original safety ratings, and facilitates precise collision repair while safeguarding drivers and passengers. This multi-stage approach includes computer simulations, physical tests, design improvements, and regular maintenance checks, ultimately enhancing vehicle longevity and safety.

“Structural Safety Verification (SSV) is a cornerstone in modern vehicle manufacturing, ensuring long-term integrity and passenger safety. This meticulous process involves rigorous testing and advanced technologies to identify and mitigate potential structural weaknesses. From computer-aided design (CAD) simulations to 3D modeling, these tools revolutionize integrity assessment. Furthermore, continuous monitoring post-manufacture through structural health monitoring extends the lifespan of vehicles, providing peace of mind for drivers. Discover how SSV maintains vehicle robustness and safety throughout their lifecycle.”

- Understanding Structural Safety Verification

- – Definition and significance in vehicle manufacturing

- – Key components involved in the process

Understanding Structural Safety Verification

Structural Safety Verification (SSV) is a critical process that ensures vehicles maintain their structural integrity over time. It involves rigorous testing and analysis to verify that every component of a vehicle, from its frame to individual panels, meets stringent safety standards. This meticulous verification goes beyond simple visual inspections, employing advanced technologies like computer-aided design (CAD), finite element analysis (FEA), and 3D scanning to predict and prevent potential failures. By identifying weak points or areas prone to damage during automotive collision repair, SSV plays a pivotal role in enhancing vehicle safety.

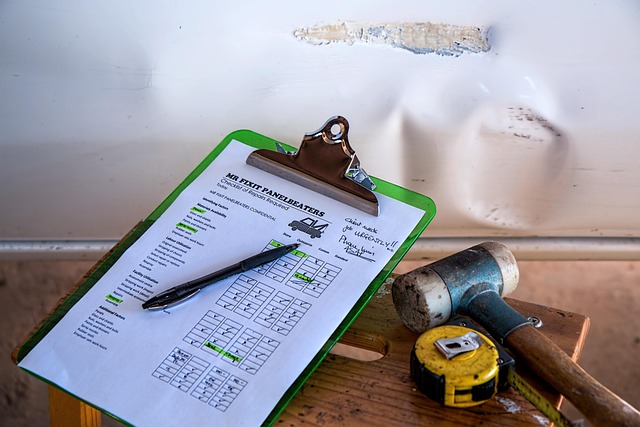

In the event of an accident, understanding how a vehicle’s structure behaves under stress is essential for effective repairs. SSV provides collision repair shops with detailed information about each part, enabling them to carry out precise and thorough vehicle body repair while preserving structural stability. This ensures that when a car undergoes its metamorphosis from damaged to restored, it retains its original safety ratings, protecting drivers and passengers alike on the road.

– Definition and significance in vehicle manufacturing

Structural safety verification plays a pivotal role in ensuring the long-term integrity and reliability of vehicles. It’s a meticulous process that involves rigorous testing and evaluation of a vehicle’s structural components, from frame to body panels, to guarantee their strength, durability, and safety under various conditions. This is not merely about adhering to stringent industry standards; it’s about safeguarding lives on the road. Every component, especially those in the vehicle bodywork, must withstand unexpected forces, accidents, and wear and tear over time without compromising structural integrity.

In an automotive body shop, skilled professionals employ advanced technologies and methodologies to conduct these verifications. This includes computer-aided design (CAD) for detailed analysis, finite element analysis (FEA) to simulate real-world stresses, and non-destructive testing techniques to inspect hidden areas without damaging the vehicle. The goal is not just to meet minimum requirements but to exceed them, ensuring that every vehicle leaving the shop is safe, sound, and ready to navigate the world’s varied road conditions for years to come, regardless of whether it’s undergoing routine vehicle repair or facing unexpected challenges on the open road.

– Key components involved in the process

The process of structural safety verification is a multifaceted endeavor designed to safeguard vehicles over their entire lifespan. It involves several critical components that work in harmony to ensure the vehicle’s integrity remains uncompromised. Firstly, detailed computer simulations are employed to model the complex interactions within a vehicle’s structure under various conditions, from sudden impacts to gradual wear and tear. These simulations serve as a foundational step, providing a digital blueprint for potential weaknesses or areas of concern.

Subsequently, physical testing is conducted using specialized equipment to validate the results of the simulations. This phase includes dynamic tests like crash simulations and static assessments that scrutinize the vehicle’s response to external forces. The data gathered from these tests is meticulously analyzed by experts who compare it against established safety standards. Any discrepancies or vulnerabilities identified are further probed, leading to targeted improvements in design or manufacturing processes. Regular maintenance checks, often undertaken by vehicle body shops, also play a pivotal role by addressing issues like car scratch repair or minor car dent repairs, ensuring the structural integrity remains intact.

Structural Safety Verification (SSV) plays a pivotal role in ensuring the long-term integrity of vehicles. By meticulously examining and validating the structural components, SSV guarantees that vehicles maintain their strength, stability, and safety standards over time. This comprehensive process involves advanced simulations, rigorous testing, and continuous monitoring, addressing potential flaws before they become critical issues. Embracing SSV is not just a compliance requirement but a commitment to fostering safer, more reliable transportation for years to come.