Digital frame measuring technology is revolutionizing vehicle damage assessment by providing precise, digitized measurements through specialized sensors and software. This advanced system enhances consistency and reliability compared to manual methods, detecting even subtle misalignments or deformities that might be missed visually. By facilitating accurate car dent repair and addressing potential structural weaknesses, digital frame measuring improves safety and efficiency in modern collision repair services. Its application extends beyond automotive to industries like construction and restoration, offering faster, more accurate inspections through advanced sensors and software, preventing damage escalation and leading to cost savings and enhanced safety.

Digital Frame Measuring (DFM) revolutionizes structural inspection by revealing hidden damage with unprecedented accuracy. This advanced technology employs sophisticated sensors and software to capture precise measurements, enabling professionals to detect minute defects within building frames. By comparing these data against established standards, DFM identifies potential risks, ensuring safety and informing informed decision-making. Beyond construction, its applications span infrastructure maintenance, historical preservation, and quality control, making it an indispensable tool for modern industries.

- Understanding Digital Frame Measuring Technology

- The Role of Digital Measuring in Detecting Structural Damage

- Benefits and Applications in Construction and Beyond

Understanding Digital Frame Measuring Technology

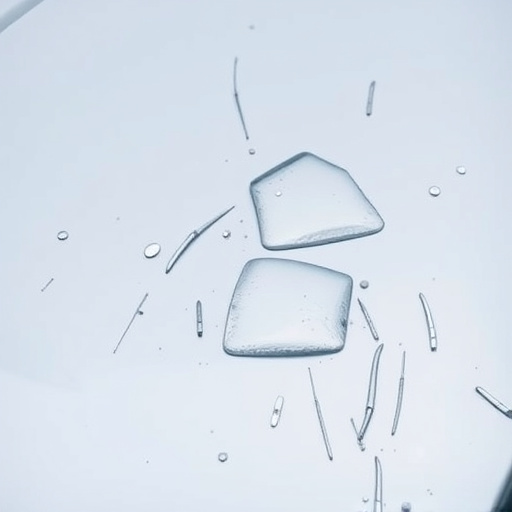

Digital frame measuring technology has revolutionized the way structural damage in vehicles is detected and assessed. This advanced system utilizes specialized sensors and software to capture precise measurements of a vehicle’s frame, providing an accurate representation of any deformation or misalignment. By digitizing the measurement process, this technology offers greater consistency and reliability compared to traditional manual methods.

In the realm of vehicle collision repair, understanding digital frame measuring is crucial for ensuring effective and efficient repairs. It aids technicians in identifying hidden damage, such as subtle misalignments or deformations that may be difficult to spot with the naked eye. This not only facilitates more accurate car dent repair but also prevents potential safety hazards associated with unaddressed structural weaknesses, making it an indispensable tool in modern vehicle paint repair and overall collision repair services.

The Role of Digital Measuring in Detecting Structural Damage

Digital frame measuring plays a pivotal role in detecting hidden structural damage in vehicles, revolutionizing the traditional approach to car repair services and auto maintenance. Unlike manual inspections that may overlook subtle issues, digital technology enables precise and comprehensive assessments. With advanced sensors and software algorithms, these systems can identify even the slightest deformities or misalignments within a vehicle’s frame.

This innovative method goes beyond what the naked eye can perceive, ensuring that every angle and contour are meticulously scanned. By capturing detailed data, digital frame measuring provides a clear picture of a vehicle’s structural integrity, allowing mechanics to make informed decisions during vehicle repair. It acts as a powerful tool in the arsenal of car repair services, fostering safer and more efficient auto maintenance practices.

Benefits and Applications in Construction and Beyond

The application of digital frame measuring technology has revolutionized the way structural damage is detected and assessed, particularly in the construction industry. This innovative tool offers numerous benefits over traditional methods, ensuring faster, more accurate, and efficient inspections. By utilizing advanced sensors and software, digital frame measuring devices can non-invasively scan structures, identifying even the subtlest signs of hidden damage. This capability is invaluable for identifying structural integrity issues before they escalate, leading to significant cost savings and enhanced safety.

Beyond construction, the advantages extend to various sectors, including car restoration and collision repair shops. Digital frame measuring plays a pivotal role in these fields by enabling precise measurements and assessments of vehicle frames after accidents. Accurate detection of damage helps technicians make informed decisions during repairs, ensuring that cars are restored to their pre-collision condition with meticulous precision. This technology’s versatility and efficiency have made it an indispensable asset for professionals across diverse industries, promoting higher standards of quality and safety in both construction and automotive sectors.

Digital frame measuring technology is revolutionizing the way we detect hidden structural damage, offering a robust and efficient solution for construction professionals. By utilizing advanced digital tools, this method provides accurate and detailed insights into building frameworks, ensuring safety and reliability. The benefits extend far beyond construction, as this innovative approach can be applied across various industries, enhancing infrastructure maintenance and driving progress in a data-driven manner.