Fiberglass repair in collision work presents unique challenges due to its complex construction and material properties. Skilled technicians require specialized training and tools, such as wet sanding and composite kits, to address non-linear cracks and breaks accurately. This meticulous process ensures the restored vehicle maintains structural integrity, aesthetic appeal, water resistance, and future safety standards without compromising performance.

Fiberglass repair in collision work isn’t your average car fix. The unique challenges posed by this composite material require skilled technicians who understand its properties and behavior. Unlike traditional metal, fiberglass is delicate, demanding precision handling during repairs. This article delves into the specific skills needed for effective fiberglass collision repair, highlighting the benefits of having experts who can ensure structural integrity, maintain original aesthetics, and deliver long-lasting results.

- The Unique Challenges of Fiberglass Materials

- – Properties and behavior of fiberglass in collision repair

- – Delicate nature and need for precision handling

The Unique Challenges of Fiberglass Materials

Fiberglass materials present unique challenges for collision repair work due to their intricate construction and inherent properties. Unlike traditional metal bodies, fiberglass structures are composed of layers of reinforced fabric soaked in resin, creating a complex and delicate composition. This complexity requires specialized knowledge and skills from technicians engaging in fiberglass repair collision work.

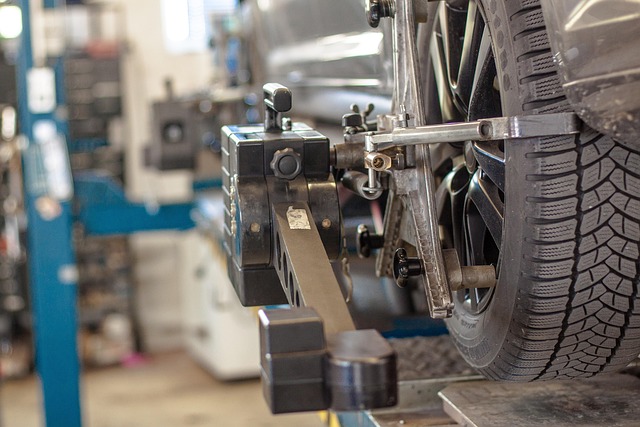

The unique nature of fiberglass also means it behaves differently when damaged. Cracks or breaks may not always be linear or easily accessible, requiring precise and meticulous techniques to repair. Additionally, the materials’ ability to absorb impact energy during a vehicle collision can lead to complex damage patterns that demand a thorough understanding of structural integrity. Car repair services specializing in fiberglass must possess the expertise to assess these intricate damages accurately, ensuring the restored vehicle retains its strength and aesthetic appeal. Auto glass repair techniques specifically tailored for fiberglass further emphasize the need for specialized training, as replacing or repairing shattered or cracked panels requires careful handling to maintain the material’s integrity and structural contribution to the overall vehicle frame.

– Properties and behavior of fiberglass in collision repair

Fiberglass, a synthetic material known for its durability and lightweight properties, presents unique challenges when it comes to collision repair. Unlike traditional metal bodies, fiberglass has distinct characteristics that demand specialized skills and techniques. When a vehicle with a fiberglass composite body incurs damage, such as cracks, breaks, or delaminations, repairing it requires a deep understanding of the material’s behavior.

In a collision center setting, auto detailing experts must carefully assess the extent of the damage to determine the appropriate repair method. Fiberglass is susceptible to water absorption, which can lead to further structural compromise if not addressed properly. Therefore, skilled technicians employ specialized tools and techniques, such as wet sanding, composite repair kits, and precision sculpting, to restore the car body to its original state. This meticulous process involves precise cuts, careful layering of fiberglass sheets, and expert application of resins, ensuring a seamless finish that matches the vehicle’s aesthetic and structural integrity, without compromising future performance or safety in the event of another collision.

– Delicate nature and need for precision handling

The world of fiberglass repair collision work demands a unique set of skills and an unwavering attention to detail. This is because the material, though lightweight and strong, is incredibly delicate, making it challenging to handle during the repair process. Every movement must be executed with precision; any misstep could lead to damage or impair the structural integrity of the vehicle.

Skilled technicians in a reputable collision repair shop understand that fiberglass isn’t like traditional metal. It requires specialized tools and techniques to ensure an effective and lasting fix. The goal is to restore the car’s auto body restoration to its original condition, achieving seamless results that blend with the rest of the vehicle—a testament to the craftsmanship and expertise involved in this meticulous auto body repair process.

Fiberglass repair in collision work stands out as a specialized skill set due to the unique challenges posed by this material. Understanding the delicate properties of fiberglass, such as its strength and flexibility, is crucial for effective repairs. Precision handling is essential to match the original shape and finish, ensuring structural integrity and aesthetic appeal. This level of expertise requires dedicated training and experience in fiberglass repair collision work, setting it apart from conventional automotive body repairs.