Spot welding equipment revolutionizes vehicle frame repair by offering precise, efficient welds that maintain structural integrity, minimize material removal, and reduce labor costs. This technology streamlines the process, saves time, and enhances customer satisfaction through faster turnaround times and high-quality finishes, making it a crucial tool for auto body shops and a game-changer in automotive collision repair and paintless dent repair.

Spot welding equipment has revolutionized vehicle frame repair, offering a range of benefits that surpass traditional methods. This article explores the advantages of integrating modern spot welding technology into automotive workshops. From enhanced precision and efficiency to improved safety and structural integrity, these machines streamline repairs, reduce costs, and minimize downtime. Discover how the latest advancements in spot welding equipment are transforming the landscape of vehicle frame restoration, ensuring superior quality and long-lasting results.

- Advantages of Spot Welding Equipment for Precision and Efficiency

- Enhanced Safety and Structural Integrity in Vehicle Frame Repair

- Cost-Effectiveness and Time Savings with Modern Spot Welding Technology

Advantages of Spot Welding Equipment for Precision and Efficiency

The use of spot welding equipment offers significant advantages in vehicle frame repair, setting a new standard for precision and efficiency in auto bodywork. Unlike traditional joining methods, spot welding provides precise control over heat input, allowing technicians to make clean, accurate welds with minimal distortion. This level of precision is crucial when realigning or restructuring damaged vehicle frames, ensuring structural integrity and safety without unnecessary material removal or additional stress on the frame.

Moreover, spot welding equipment streamlines the repair process in body shop services, saving valuable time and resources. The focused heat application minimizes the risk of overheating or damaging surrounding materials, reducing the need for extensive sandboarding, filling, or painting later on. This efficiency not only cuts down on labor costs but also benefits tire services by minimizing the downtime required for vehicle repairs, ensuring faster turnaround times and happier customers.

Enhanced Safety and Structural Integrity in Vehicle Frame Repair

Using spot welding equipment in vehicle frame repair offers significant advantages when it comes to enhancing safety and structural integrity. Unlike traditional welding methods that can lead to excess heat damage and distortion, spot welding is a precise process that allows for localized heating and cooling. This ensures that only the necessary metal areas are affected, preserving the overall structural integrity of the vehicle frame. The result is a stronger, more stable car body, crucial for maintaining safety standards during accidents and everyday driving.

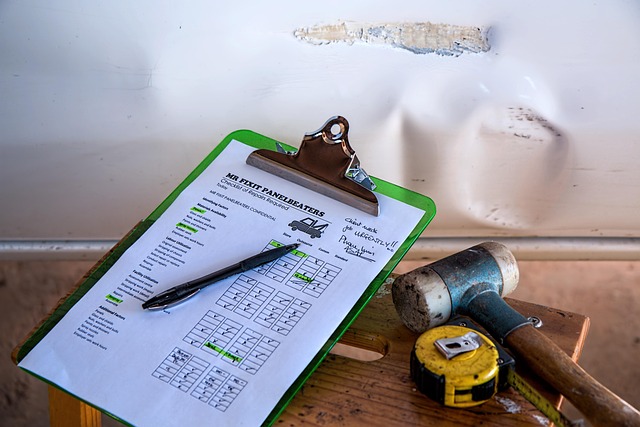

In an auto body shop or car repair facility, spot welding equipment plays a pivotal role in ensuring quality repairs. It facilitates efficient dent removal and precise alignment of metal panels, contributing to a seamless finish. By minimizing the risk of structural weaknesses and compromising the car’s overall safety, spot welding is an indispensable tool for skilled technicians in their efforts to restore vehicles to their optimal condition, enhancing customer satisfaction and road safety.

Cost-Effectiveness and Time Savings with Modern Spot Welding Technology

The adoption of modern spot welding equipment has revolutionized both automotive collision repair and paintless dent repair processes. Traditional methods often required more time and labor, leading to higher costs. However, spot welding technology offers a more efficient solution. This innovative approach allows for precise, quick, and strong welds, significantly reducing the time spent on frame repairs. With its ability to deliver consistent results, spot welding equipment ensures that vehicle frames are restored to their original integrity without incurring excessive labor charges.

By utilizing this advanced technology, repair shops can streamline their operations, enabling them to handle more vehicles in less time. This not only benefits the workshop by increasing productivity but also guarantees faster turnaround times for customers undergoing vehicle paint repair. As a result, modern spot welding equipment plays a pivotal role in enhancing the overall efficiency and cost-effectiveness of automotive frame repair services.

Spot welding equipment offers a multitude of benefits for vehicle frame repair, from precision and efficiency to enhanced safety and structural integrity. The cost-effectiveness and time savings provided by modern spot welding technology make it an indispensable tool in the automotive industry. By leveraging these advantages, professionals can ensure higher quality repairs, faster turnaround times, and ultimately, better value for their customers.