Mercedes' unibody construction, a hallmark of luxury and safety, requires specialized care in case of accidents. Controlled repair environments and skilled technicians ensure precise, high-quality Mercedes unibody repairs. The process involves meticulous inspection, disassembly, frame straightening with advanced equipment, and expert paintwork to match the vehicle's original aesthetics, preserving structural integrity and aesthetic appeal.

Mercedes unibody repairs demand precision and control, making a dedicated, controlled repair environment ideal. This article delves into the intricacies of Mercedes unibody construction, highlighting its structural significance. We explore the advantages of specialized repair facilities for ensuring optimal results. Furthermore, a comprehensive step-by-step guide is provided to conduct Mercedes unibody repairs in such environments, emphasizing best practices for accurate and reliable restoration.

- Understanding Mercedes Unibody Construction and Its Importance

- The Benefits of Controlled Repair Environments for Unibody Repairs

- Step-by-Step Guide to Conducting Mercedes Unibody Repair in a Controlled Setting

Understanding Mercedes Unibody Construction and Its Importance

Mercedes unibody construction is a complex yet sophisticated process that plays a pivotal role in vehicle safety and structural integrity. The unibody, or monocoque, design is characterized by a solid, integrated structure that houses and protects the passenger compartment, engine, and other components. This innovative architecture is a hallmark of Mercedes-Benz vehicles, renowned for their luxury and performance. Understanding this construction method is crucial for effective Mercedes unbody repair when accidents occur.

In an auto collision repair scenario, preserving the original unibody’s precision and integrity is essential. The controlled environment of a specialized workshop allows for meticulous restoration, ensuring the vehicle returns to its pre-accident condition. Skilled technicians employ advanced techniques and tools to realign panels, replace damaged parts, and refinish surfaces, ultimately facilitating a seamless blend with the existing structure. This level of expertise is vital in achieving not just functional restoration but also maintaining the vehicle’s renowned quality and safety standards, all within the context of collision repair services.

The Benefits of Controlled Repair Environments for Unibody Repairs

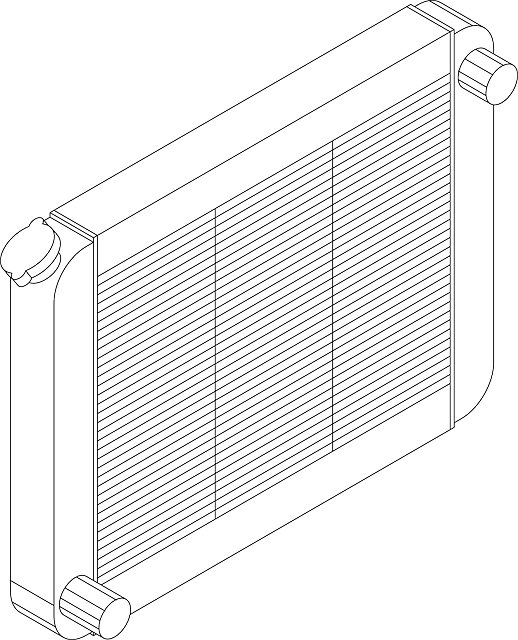

Controlled repair environments offer numerous advantages for Mercedes unibody repairs, ensuring precision and quality. These dedicated facilities are designed to mimic the original manufacturing conditions, providing a consistent and controlled atmosphere. This is particularly beneficial for complex car body repair processes like frame straightening, as it allows technicians to work with accuracy and efficiency.

With advanced equipment and specialized tools readily available, collision repair services in these environments streamline the repair process. The controlled setting also minimizes the risk of further damage, ensuring that every aspect of the unibody is meticulously addressed. This level of care results in superior structural integrity and aesthetics for the vehicle, making it a preferred approach for both professional mechanics and car owners seeking top-tier Mercedes unibody repair solutions.

Step-by-Step Guide to Conducting Mercedes Unibody Repair in a Controlled Setting

Conducting Mercedes unibody repair in a controlled setting involves a meticulous process designed to ensure precision and quality. It begins with a thorough inspection of the damaged area, identifying each component that requires attention. This initial step is crucial as it dictates the subsequent actions, including disassembly and separation of affected parts from the vehicle’s frame. Once isolated, the damaged sections are carefully evaluated for extent of harm, with advanced diagnostic tools aiding in accurate assessments.

The repair process itself demands a structured approach. After cleaning and preparing the surface, skilled technicians use specialized equipment to straighten and align the contorted metal. This precise manipulation returns the unibody to its original specifications, ensuring structural integrity. Following alignment, auto body repair experts carefully inspect for any remaining imperfections, using fine tools to address them. Finally, car paint repair techniques are employed to match the color and finish precisely, blending seamlessly with the vehicle’s existing aesthetics.

Mercedes unibody repair, a specialized process, benefits greatly from controlled repair environments. By implementing these settings, technicians can ensure precise and consistent results. This article has outlined the significance of Mercedes unibody construction, the advantages of such controlled environments, and provided a step-by-step guide to facilitate efficient repairs. Embracing these practices ensures not only high-quality work but also streamlines the repair process for optimal customer satisfaction.