Computer-aided repair design (CARD) is revolutionizing auto body repair with enhanced precision and efficiency. By creating digital vehicle models, CARD software allows technicians to plan and execute repairs accurately, detect issues early, and minimize costly rework. This technology streamlines the entire repair process from measurement to welding, resulting in faster, more consistent, and high-quality outcomes. Through precise measurements, quick modifications, and instant visual feedback, CARD reduces human error, particularly in complex restoration projects. Ultimately, CARD offers substantial time and cost savings for auto body shops, customers, and clients alike, making it an essential investment for modern automotive service providers.

In today’s digital era, investing in Computer-Aided Repair Design (CARD) is not just an option—it’s a strategic necessity. This technology is revolutionizing repair processes by offering unprecedented efficiency and precision, saving time and costs while minimizing human error. From enhancing problem-solving capabilities through complex troubleshooting to adapting future-proof skills for emerging trends, CAD is the game changer that prepares you for today’s challenges and tomorrow’s opportunities.

- Efficiency and Precision: Revolutionizing Repair Processes

- – Exploring the time and cost savings of computer-aided design (CAD) in repair work

- – Improved accuracy and reduced human error with CAD technology

Efficiency and Precision: Revolutionizing Repair Processes

Computer-aided repair design is transforming the way auto body work and vehicle dent repairs are conducted, marking a significant leap in precision and efficiency for body shop services. This innovative technology leverages advanced software to create detailed digital models of vehicles, allowing technicians to plan and execute repairs with unparalleled accuracy. By offering real-time visualization and simulation capabilities, computer-aided repair design enables technicians to detect potential issues early on, minimizing errors and the need for costly rework.

This method also streamlines the entire repair process, from measuring and estimating to cutting and welding. With precise measurements and cut lines, repairs are not just faster but also more consistent, ensuring each vehicle leaves the body shop looking as good as new. The level of detail and accuracy afforded by computer-aided repair design sets a new standard for quality in auto body work and vehicle dent repair, making it an indispensable investment for modern body shops.

– Exploring the time and cost savings of computer-aided design (CAD) in repair work

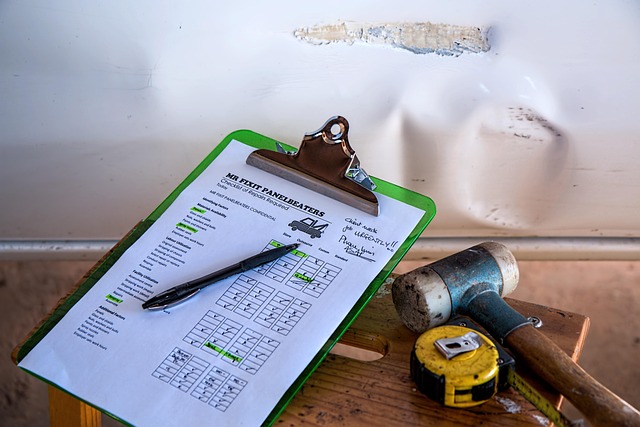

Computer-aided repair design (CAD) offers significant advantages for auto body shops and collision centers, resulting in substantial time and cost savings. By leveraging digital technology, professionals can streamline their work processes, reducing manual labour and potential errors. This efficiency is particularly noticeable in complex auto body restoration projects. CAD software allows for precise measurements, quick modifications, and instant visual feedback, ensuring repairs are accurate from the outset.

Moreover, these tools enable faster project completion times, as designers can quickly generate detailed plans and specifications. This benefits both customers and repair facilities by accelerating turnaround times without compromising quality. With modern CAD systems, auto body shops can compete in a rapidly evolving market, offering efficient and precise services that were once time-consuming manual tasks.

– Improved accuracy and reduced human error with CAD technology

Computer-aided repair design (CARD) technology has revolutionized auto repair services, bringing about a significant shift in precision and efficiency. Unlike manual methods, CARD systems offer improved accuracy, minimizing human error that can occur during complex repairs. This advanced technology allows technicians to access detailed digital blueprints of vehicles, enabling them to perform even the most intricate tasks with enhanced confidence and speed.

One area where this is particularly evident is in paintless dent repair, a process that requires meticulous attention to detail. With CARD, auto body shops can accurately assess damage, plan repairs, and execute them flawlessly, resulting in superior customer satisfaction. By streamlining workflows and reducing the need for trial-and-error methods, CARD also contributes to cost savings for both repair facilities and their clients, making it a game-changer in the field of automotive collision repair.

Computer-aided repair design is no longer a luxury but an essential tool for modern repair processes. By embracing this technology, businesses can achieve remarkable efficiency gains, reduce costs, and minimize errors. The benefits are clear: faster turnaround times, improved product quality, and enhanced customer satisfaction. Investing in CAD today positions your business as a leader, ensuring a competitive edge in tomorrow’s digital landscape.