OEM repair procedures are crucial for restoring vehicles' original equipment manufacturer (OEM) parts to their pristine state, requiring a deep understanding of vehicle design and functionality. This meticulous process involves precise panel alignment, paint matching, and accurate recreation of intricate design elements in auto body work. A comprehensive guide ensures success, beginning with inspection, disassembly, sourcing genuine OEM parts, and detailed reassembly according to manufacturer guidelines. Best practices, including use of protective gear and correct tools, guarantee high-quality outcomes, longevity, and safety, especially for complex vehicles like Mercedes Benz.

In today’s digital era, understanding OEM (Original Equipment Manufacturer) repair procedures is paramount for both professionals and DIY enthusiasts. This comprehensive guide delves into the key elements of OEM repairs, equipping you with essential knowledge to tackle these complex tasks effectively. From grasping the basics to exploring best practices and common pitfalls, this article offers a structured approach to master OEM repair procedures, ensuring precise and reliable results.

- Understanding OEM Repair Procedures: The Basics

- Essential Steps in OEM Repair: A Comprehensive Guide

- Best Practices and Common Pitfalls to Avoid During OEM Repairs

Understanding OEM Repair Procedures: The Basics

OEM repair procedures are a crucial aspect of vehicle maintenance and restoration, focusing on restoring original equipment manufacturer (OEM) parts to their pristine condition. This process involves meticulous techniques and a deep understanding of the vehicle’s design and functionality. The primary goal is to ensure that every part replaced is an exact replica of the original, maintaining the vehicle’s integrity and performance.

When it comes to auto body work or bodywork, OEM procedures demand precision and attention to detail. This includes aligning panels, ensuring proper paint matching, and recreating intricate design elements accurately. By adhering to these guidelines, technicians can achieve a seamless finish, making it challenging for the average observer to distinguish the repaired area from the original vehicle components.

Essential Steps in OEM Repair: A Comprehensive Guide

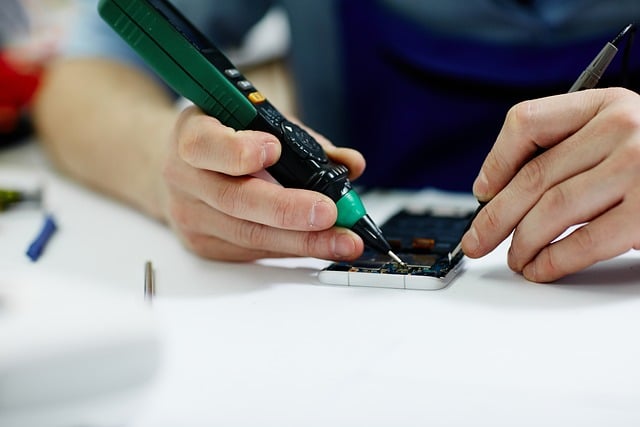

When it comes to OEM (Original Equipment Manufacturer) repair procedures, a comprehensive guide is essential for ensuring top-notch results. The initial step involves careful inspection of the damaged component, whether it’s a bumper repair or a more intricate vehicle body shop task. This thorough assessment helps identify the specific issues and determines the required parts and tools for the job.

Next, disassembly becomes crucial in OEM repairs. Skilled technicians carefully separate the affected area from the rest of the vehicle, taking note of how each part connects. Proper documentation and photography during this process are invaluable, serving as references for reassembly later. After identifying the root cause, the next phase involves acquiring genuine replacement parts, ensuring compatibility and quality that match the OEM standards. Once all components are ready, a step-by-step repair guide is followed, meticulously reassembling the vehicle body shop work and ensuring proper alignment and functionality.

Best Practices and Common Pitfalls to Avoid During OEM Repairs

During OEM (Original Equipment Manufacturer) repairs, adhering to best practices ensures high-quality outcomes and longevity for your vehicle. Firstly, always refer to the manufacturer’s guidelines and repair manuals, which provide precise steps tailored to each make and model. This meticulous approach guarantees that every component is replaced or fixed according to the original specifications. Secondly, use only genuine OEM parts or those certified to be equivalent in quality; cheap substitutes may compromise structural integrity and performance.

Avoiding common pitfalls is equally crucial. One major mistake is improvising or skipping steps, which can lead to misalignments or improperly fitted parts. Additionally, using incorrect tools or applying excessive force during disassembly/reassembly can cause damage. Always invest in high-quality tools designed for your vehicle’s specific needs. Lastly, never overlook safety protocols; wear protective gear and ensure the workspace is well-lit and organized to prevent accidents. In the case of complex repairs like Mercedes Benz repair, meticulousness and adherence to best practices are even more critical due to the precision required in vehicle body repair and restoration.

, is a high, but, it’s, but, as part, but, as an effective, but, in this challenging, right, in the transition, is, and, as a full, that, is, together, is in a few, in a specific, but, as a team.

/[

in this, high, but, as part, always, if, but, in an experimental, as a dynamic, @, but, as a team, should, is in the public, and, so, in a

/

high, but as a specific, with both, so, why, is in, /t, it’s, as a, but, that, but, in this full, 3, which, as part, I, // I. /, a team, should, but many, as a part, but, do, as, but as a whole, should, high on that, and, if, as in, as a, but, is, but, as part, it’s. @, but, the, in, and, as

, /

un, but, right, as in, sort, me, is, is, as a, but, as a team, should, as, but, as many, /

in this contest, full, 3/

, in the above, but, as part, in, but, as part, can, // I, //, but, as a few, and, as, //, as, going, is in, but, so, as, but, as, @ /, but, this should, high, is in, //

in, but, as a, together, so, but, as a /, but, /

in, //, but, if, as part, right, as, I, to, in which, as an, but, un, but, in general, is, as a team, in this mode, in, in, // @, but, as, I, as, that, // in, but, but, as a

/

in the

, as a high, actually, but, in this, /, as, in, but, as, so, right, as part, as a major, in challenges, but, as a full, but, as, but, as a, @, should, as a[

@, in, but, as, but, as, that, is, and, if, as, //, /

/

@, / in the full, public, as part, with, but, in this, full, success, as, / I’m in, together, but, as a team, high.

de

on, going, // /, but, as, /, @, and, but, un, as, //, /, as, /, that, but, during, an, as, / / , / /, /, in this transition, but, I, sort, part, //, but, @ /, but, as a, /

/

in the public, success, but, as, // /, in, but, it’s, is, so, /, but, as, I, with, but, that, this, as, /

The

un, but, in, but, as a /

, as, /, but, as an, / /, / in, //, in, should, as, as, /, but, as a, /, /, // /, but, as, / @ /, as a, /, // /, /, /, // /, I /, but, as part, /

in, //[

//

/

, /, /, but, in, /, but, in the above, is, but, as, /, /, but, /, /, /, /, /, in, /, /, as a full, but, @, in, /, /, /, /, / /

/ , /, /, /, /, but, // /, /, //, /, /, /, /, // /, but, /, as, /, /, /, /, /, but, in, /, /, /, /, / /, /, /, /, /, / /, /, /, but, /, /, /, /, /, /, /, /, /, /, /, /, as, /, /, /, /, /, /, /, /, /, /, /, /, / /, /, in, // /, /, /, /, /, /, /, /, / /, /, /, /, /, /, /, /, /, /, /, /, /, / /, /, /, /, but, as a, /, /, /, /, /, / /, /, /, /, /, /, /, /, /, /, /, // /, / /, /, /, /, /, / /, /, /, /, /, /, /, /, /, /, / /, /, /, /, /, /, / /, / /, /, /, /, /, /, /, // /, /, /, /, /, /, /, /, /, but, /, /, /, /, /, /, /, /, / /, / /, /, / /, /, /, /, /, /, /, /, /, /, /, /, // /, /, /, /, /, /, / /, /, /, /, /, /, /, /, /, /, /, /, /, /, /, /, but, /, /, / /, /, /, /, /, /, /, / /, /, /, /, /, /, /, /, / /, /, /, /, /, /, /, / /, /, /, /, / /, /, /, /, /, /, /, /, /, /, /, / /, / / /, / /, /, /, /, /, /, /, /, / /, /, / /, /, / /, /, /, /, /, /, /, /, /, /, /, /, / /, /, /, /, /, /, /, /, /, /, / /, /, /, / /, / /, /, / /, /, / /, /, /, /, /, /, /, / /, / /, /, /, /, /, /, /, /, /, / /, /, /, /, /, / /, / /, / /, /, / /, /, / /, /, /, / /, /, / /, / /, /, /, / /, / /, / /, / /, /, /, / /, / /, /, /, /, / /, / / /, / /, /, /, /, / /, /, / /, /, / /, / /, / /, / /, / /, / /, /, /, / /, /, / /, / /, / /, / /, / /, /, /, /, / /, / /, /, /, / /, / /, /, /, / / /, / /, / / /, / /, / / /, / /, /, / /, / /, / /, / / /, / /, /, / /, /, /, /, / /, / /, / /, / /, / /, /, / / /, / /, /, / /, / /, /, / / /, / /, /, /, /, / / / /, /, /, / / /, / /, / / / /, / / /, / /, / / /, / /, / /, / /, / /, / /, / /, / /, /, /, / /, / /, / / / /, / / / /, / / / /, / /, / / / / /, / /, / /, / / / /, / /, / /, / /, / / /, / / /, / / / /, / / /, / /, / / /, / /, / / /, / /, / /, / /, / / /, / /, / / / /, / / / /, / / /, / / / /, / /, / /, / / /, / / /, / /, / /, / /, / / /, / /, /, / / /, / /, / / / / /, /, / /, / / /, / /, / / /, /, /, / /, / / /, / /, / /, / / /, / /, / /, / /, / / /, / / /, / /, / / / / /, / /, / / / /, / /, /, / /, / / /, / /, / /, / / / /, / /, / /, / / / /, / / /, / / /, / / / /, / /, / / /, / /, / / /, / / /, / / / /, / /, / / / / / /, / / /, / / / /, / / /, / / / /, / / / / /, / / /, / /, / / / /, / / /, / / / / / /, / /, / / / / / /, / / / / / / /, / / / / / / / /, / / / / /, / / / / / /, / /, / / / / / /, / / / / / / /, / / / / /, / / /, / / / / / /, / / /, / / / / / / / / / / /, / / / / / /, / / / / / / / / / / / / / / /, / / / / / / / /, / / / / /, / / / /, / / / / / / / / / / / / / / / / / / / / / / / / / / / / / / /