Spot weld bonding repair is a specialized auto technique restoring door panel integrity using precise adhesive application at 'spot weld' locations. Key factors contributing to spot weld failure include inadequate preparation, material compatibility issues, and environmental exposure. Effective repair involves meticulous pre-weld cleaning, proper welding techniques, and understanding material properties. The process begins with assessment, cleaning, and applying adhesive, followed by filling voids, sanding, and matching panel color or considering paintless dent repair for an invisible fix.

In the automotive industry, ensuring robust door panel bonds is paramount for safety and structural integrity. This article delves into the intricacies of spot weld bonding repair, a specialized technique crucial for restoring vehicle doors. We’ll explore common reasons behind spot weld failures, ranging from material fatigue to manufacturing defects. Additionally, we provide a comprehensive step-by-step guide detailing effective repair methods, empowering automotive professionals with the knowledge to tackle this complex task efficiently.

- Understanding Spot Weld Bonding Repair for Door Panels

- Common Causes of Spot Weld Failure in Automotive Doors

- Step-by-Step Guide to Effective Spot Weld Bonding Repair Techniques

Understanding Spot Weld Bonding Repair for Door Panels

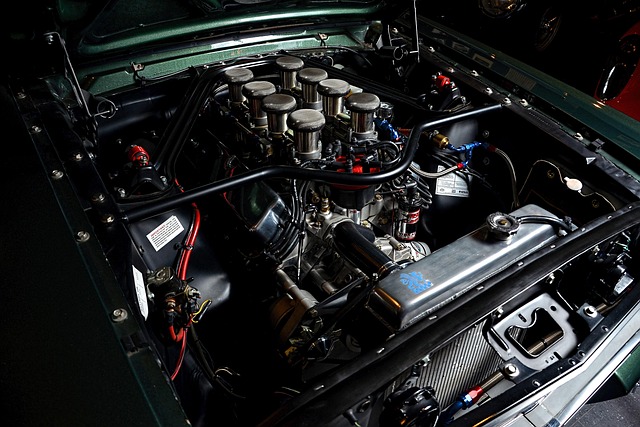

Spot weld bonding repair for door panels is a specialized technique within the auto industry, focusing on restoring structural integrity to vehicle doors. Unlike traditional welding methods, spot weld bonding repair involves precise application of adhesive to reestablish the bond between panel components. This process is particularly valuable for car bodywork services, as it offers an efficient and effective solution for damaged door panels without the need for extensive paintless dent repair techniques.

In a collision center or automotive workshop, skilled technicians identify the affected areas on the door panel, prepare the surface, and then carefully apply a high-quality adhesive at specific ‘spot weld’ locations. This ensures a strong bond between the panel parts, mimicking the original manufacturing process. The result is a durable repair that maintains the structural stability of the door, often with minimal visible signs of damage once completed.

Common Causes of Spot Weld Failure in Automotive Doors

Spot weld failure in automotive doors can stem from various factors that weaken the bond between metal components. One common cause is inadequate preparation prior to welding. This includes surface contaminants like grease, rust, or paint, which can impair the fusion process and lead to weak bonds. Insufficient heat input or incorrect welding parameters can also result in spot weld failure, as they may not be sufficient to melt and fuse the metals properly.

Another significant factor is material compatibility. Using incompatible metal types or grades in door panel construction can cause strain on the welds over time. Environmental conditions, such as exposure to extreme temperatures or corrosive substances, can accelerate wear and tear, leading to weakened spot welds. In an auto collision center or auto body shop, addressing these common causes requires meticulous pre-weld cleaning, proper welding technique, and understanding material properties to ensure effective spot weld bonding repair using car repair services.

Step-by-Step Guide to Effective Spot Weld Bonding Repair Techniques

Repairing spot weld bonding issues on door panels is a delicate process that requires precision and the right techniques. Here’s a step-by-step guide to ensure effective spot weld bonding repair:

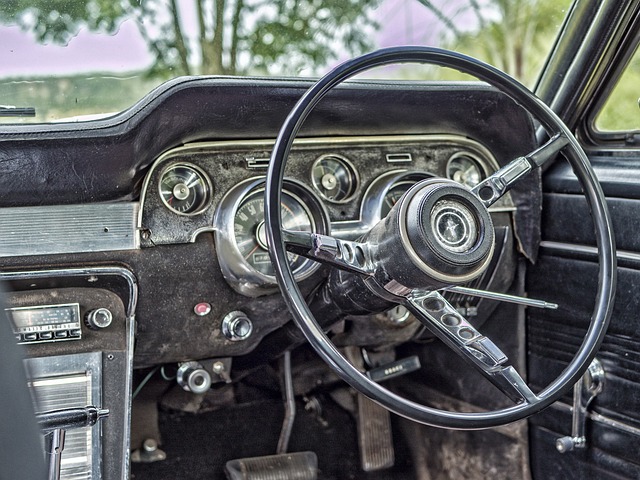

1. Assessment: Begin by thoroughly inspecting the damaged area. Identify the extent of the weld breakage or separation. This initial step is crucial in determining the appropriate repair method.

2. Preparation: Clean the affected panel meticulously. Remove any debris, rust, or old paint that might interfere with the bonding process. Surface preparation is key to achieving a strong bond. Utilise fine-grit sandpaper for a smooth finish and apply a primer to enhance adhesion.

3. Weld Repair: Using a suitable spot weld bonding repair kit, apply the adhesive along the damaged area, following the manufacturer’s instructions. Ensure the panel is held securely in place until the adhesive sets. This step might involve clamping or using specialized equipment recommended by your auto collision center.

4. Filling and Shaping: Once the adhesive is set, carefully fill the voids with a suitable filler compound. Smooth the surface to match the surrounding panel. Let it dry completely before sanding for a seamless finish.

5. Finishing Touches: After sanding, apply a coat of paint that matches the car’s original colour. This step ensures aesthetics and protects the repair. A paintless dent repair technique can also be employed if desired, offering a virtually invisible fix. Car restoration experts often recommend this method for achieving flawless results.

Spot weld bonding repair is a precise and effective method for restoring door panels, addressing the common issue of spot weld failure in automobiles. By understanding the causes of these failures, such as material fatigue or manufacturing defects, and employing step-by-step techniques, professionals can ensure robust repairs that enhance vehicle safety and structural integrity. This specialized skill set, involving precision tools and materials, contributes to high-quality automotive bodywork, maintaining the car’s overall performance and aesthetics.