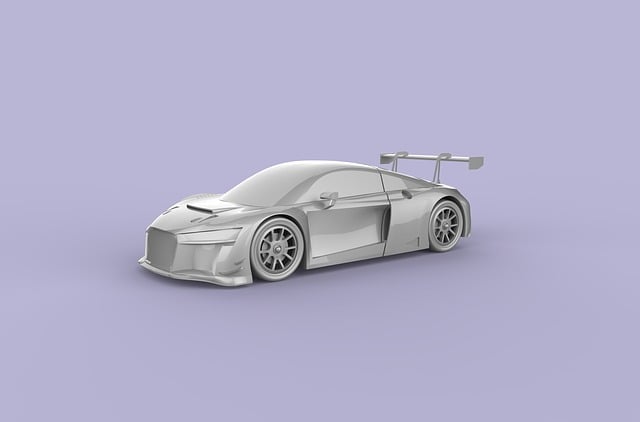

Modern car unibody designs, while visually stunning, complicate traditional maintenance and repair due to interconnected panels. Advanced panel sectioning techniques, employing technologies like laser cutting and vacuum forming, allow precise disassembly and reassembly for repairs without compromising structural integrity or aesthetics. These methods are crucial in automotive manufacturing and repair, ensuring efficient construction, reduced waste, and simplified access for modifications while maintaining the vehicle's original form and function.

Unbody designs, known for their intricate geometry and holistic form, present unique challenges in manufacturing. This article explores the critical role of panel sectioning techniques in tackling the complexities of these designs. We delve into the understanding and intricacies of complex unibody structures, highlighting the need for effective panelization strategies. Through a comprehensive overview, we present various panel sectioning techniques, offering insights to optimize design results while navigating the nuances of these challenging geometries.

- Understanding Complex Unibody Designs and Their Challenges

- Various Panel Sectioning Techniques: A Comprehensive Overview

- Implementing Effective Panel Sectioning for Optimal Design Results

Understanding Complex Unibody Designs and Their Challenges

Complex unibody designs, prevalent in modern automotive manufacturing, present unique challenges for panel sectioning during auto maintenance or auto collision repair. These intricate structures feature seamless, interconnected panels that form a vehicle’s exterior carrosserie, offering both aesthetic appeal and structural integrity. However, their complexity also makes them delicate, requiring meticulous handling and specialized techniques during frame straightening processes.

Traditional panel sectioning methods often struggle with these complex geometries, leading to issues like misalignments, cosmetic imperfections, or even structural weaknesses. Here’s where innovative panel sectioning techniques come into play. By employing advanced cutting-edge technologies and tailored approaches, professionals in auto collision repair can efficiently disassemble and reassemble these intricate unibody designs, ensuring precision, minimal damage, and optimal restoration of the vehicle to its pre-incident condition.

Various Panel Sectioning Techniques: A Comprehensive Overview

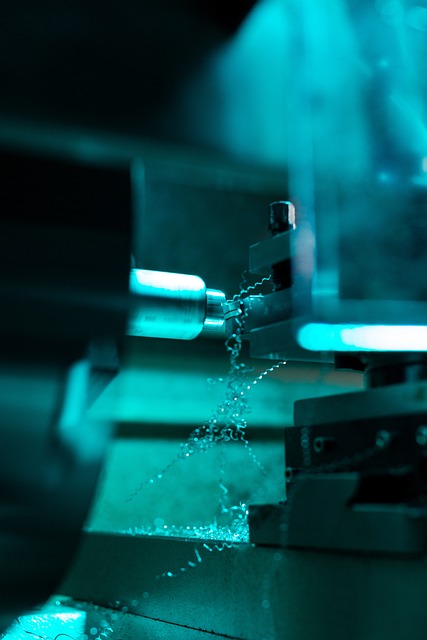

In the realm of automotive design and manufacturing, achieving complex unibody designs requires precise panel sectioning techniques. These methods play a pivotal role in shaping the car’s exterior, ensuring structural integrity while facilitating seamless assembly. The process involves cutting, forming, and joining various panels to create curved surfaces, tight radii, and intricate geometries. Among the diverse panel sectioning techniques available, laser cutting stands out for its precision and ability to handle complex shapes without compromising quality or accuracy. This method is particularly valuable in modern car bodywork services, enabling efficient production of sleek designs that were once challenging to manufacture.

Alternative techniques include water jet cutting, which utilizes a high-pressure stream of water infused with abrasive media for precise material removal, ideal for tire services and intricate components. Forming methods like press bending and roll forming are also crucial, offering flexibility in creating curved panels and complex profiles. For paintless dent repair and meticulous detailing, specialized equipment such as vacuum forming and injection molding can produce near-perfect replicas of original designs. These comprehensive panel sectioning techniques collectively empower automotive manufacturers to bring innovative unibody designs to life, enhancing both the aesthetics and functionality of modern vehicles.

Implementing Effective Panel Sectioning for Optimal Design Results

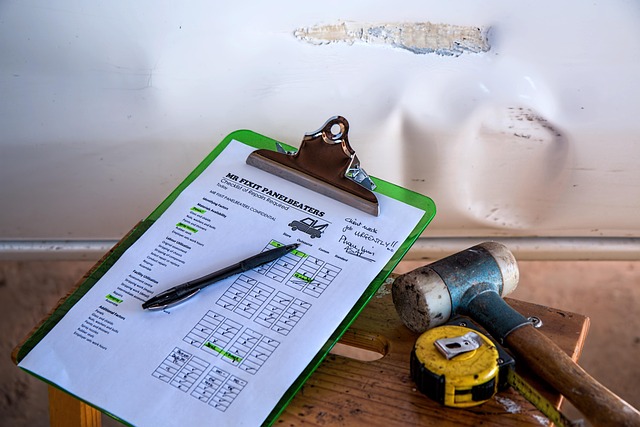

Implementing effective panel sectioning is a key aspect of achieving optimal design results in complex unibody designs, particularly within the automotive repair and vehicle body shop industries. It involves carefully dividing the body into manageable sections to simplify construction, assembly, and maintenance while preserving structural integrity. By employing strategic panel sectioning techniques, collision repair shops can enhance their efficiency, reduce material waste, and improve overall quality.

This process requires a deep understanding of the unibody’s design, including its load paths, stress concentrations, and areas prone to damage during accidents. Skilled technicians use specialized tools and software to determine the optimal cutting lines, ensuring that each panel is designed for both form and function. Proper sectioning allows for easier manipulation of parts, facilitates precise alignment during assembly, and enables efficient access for repairs or modifications in a collision repair shop setting.

In conclusion, mastering panel sectioning techniques is paramount for engineers tackling complex unibody designs. By understanding the unique challenges of these intricate structures and exploring a variety of sectioning methods, optimal design outcomes become attainable. Implementing effective strategies ensures structural integrity, material efficiency, and enhanced aesthetic appeal, ultimately revolutionizing the way we approach unibody design. These advanced techniques empower designers to navigate the complexities of modern automotive and industrial applications, delivering both performance and style.