Seam sealers, vital for automotive repairs, come in silicone or urethane varieties, each with unique advantages. Effective application requires meticulous surface preparation and control of temperature and humidity. The chosen sealant type determines the application method (gun, brush, or spray). Thorough joint preparation, including sanding and priming, ensures proper adhesion. Applying thin, even coats allows drying between layers for a seamless, durable finish that restores vehicle body to pre-collision condition.

In automotive restoration or collision repair, achieving robust and long-lasting body panel joints is paramount. This article delves into the art of seam sealer application, exploring techniques that ensure superior sealing for vehicle panels. From understanding various seam sealer types and their unique functions to preparing joints for optimal adhesion, we guide you through every step. Learn expert methods for applying seam sealer effectively, ensuring durability and water resistance in the repair process.

- Understanding Seam Sealer Types and Their Functions

- Preparing the Body Panel Joints for Sealing Application

- Effective Techniques for Applying Seam Sealer to Body Panel Joints

Understanding Seam Sealer Types and Their Functions

Seam sealers are an essential component in automotive repair, particularly for vehicle paint repair and auto dent repair. Understanding the types and functions of these sealants is crucial when executing precise seam sealer application techniques. There are primarily two types: silicone-based and urethane-based sealers. Silicone offers excellent flexibility and resistance to extreme temperatures, making it ideal for joining metal panels that experience significant movement, a common occurrence in auto repair shops. On the other hand, urethane sealers provide superior durability and chemical resistance, rendering them suitable for environments exposed to harsh chemicals or consistent weathering.

During seam sealer application, factors such as surface preparation, temperature, and humidity play a pivotal role in achieving optimal results. Proper surface cleaning ensures adhesion, while controlling environmental conditions maximizes the sealant’s effectiveness. The chosen sealer type dictates the specific application method—either by gun, brush, or spray—ensuring seamless (pun intended) integration of the repair into the original auto dent repair process.

Preparing the Body Panel Joints for Sealing Application

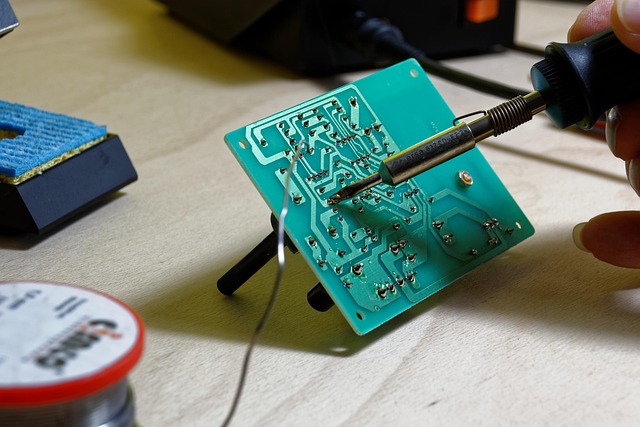

Before applying any seam sealer, it’s crucial to prepare the body panel joints thoroughly for optimal results in auto body work. This involves a series of steps designed to ensure cleanliness and smoothness, two key factors that determine the effectiveness of the sealant. Begin by thoroughly washing the joint area with mild soap and water to remove any dirt, grease, or debris. Drying the surface is then essential, as moisture can interfere with the adhesion of the sealer. A clean, dry surface ensures a smooth application process and promotes better bonding between the sealer and the panel.

Additionally, sanding the joint edges can help create a rough texture that enhances sealant adhesion. Removing any existing loose paint or rust is also critical, as these defects can prevent the sealant from creating a continuous bond. In automotive repair, proper preparation of body panel joints is half the battle won; it lays the foundation for not just a functional but also an aesthetically pleasing finish, achieved through what’s known as seam sealer application techniques.

Effective Techniques for Applying Seam Sealer to Body Panel Joints

Applying seam sealer to car body panel joints requires a thoughtful approach for optimal results in auto body repair. Effective techniques involve preparing the joint surface thoroughly before application, ensuring it’s clean and free from any debris or grease. This may include sanding and priming to create a rough texture that aids better adhesion.

Use a thin, even coat of seam sealer, applying it with a suitable tool such as a brush or roller. For complex car collision repair or intricate bodywork, a spray application might be more precise. Allow the initial coat to dry completely before adding subsequent layers, following the manufacturer’s guidelines for drying times. This process helps create a seamless and durable finish, repairing the car body to its pre-collision condition.

Seam sealer application is a crucial step in ensuring the integrity and durability of body panel joints. By understanding the different types of seam sealers and their functions, preparing the joints properly, and employing effective application techniques, automotive professionals can achieve robust sealing, enhancing vehicle performance and longevity. These strategies are essential for maintaining the structural integrity of vehicles, especially during repair or reconstruction projects.