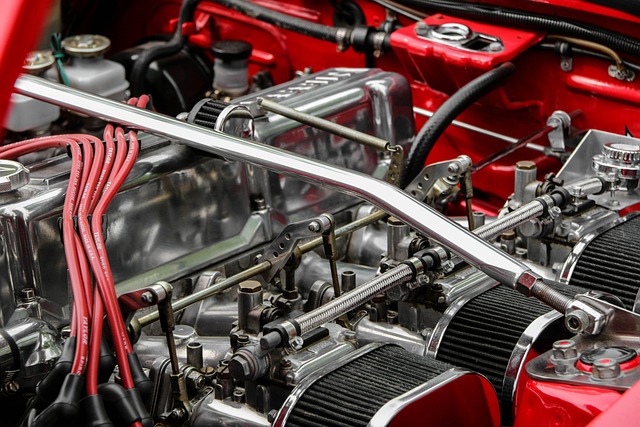

Collision repair shops can dramatically enhance efficiency and quality with UV paint curing systems. These systems use ultraviolet light for swift paint drying, reducing repair times by up to 70% compared to traditional methods. By minimizing imperfections, UV curing ensures seamless finishes that meet high auto detailing standards. This advanced technology allows shops to increase throughput, reduce labor costs, minimize rework, and deliver superior customer satisfaction, ultimately boosting market competitiveness.

In today’s fast-paced automotive industry, repair shop efficiency is paramount. Traditional paint drying methods, relying on time-consuming processes like air drying or oven baking, can hinder productivity. This is where UV paint curing systems emerge as a game-changer. By utilizing ultraviolet light to swiftly cure paint, these systems significantly enhance repair shop workflows, reducing dry times and enabling faster turnaround for customers. In this article, we explore the advantages of UV paint curing technology in detail.

- Understanding Traditional Paint Drying Methods and Their Drawbacks

- The Advantages of UV Paint Curing Systems: Speed and Efficiency

- Integrating UV Curing into Repair Shop Workflows for Optimal Results

Understanding Traditional Paint Drying Methods and Their Drawbacks

In traditional paint drying methods, collision repair services often rely on open-air curing or the use of heat guns. While these techniques have been in practice for years, they come with several drawbacks that impact shop efficiency and overall quality. Open-air curing is a slow process, as paint needs time to evaporate naturally, making it less practical for high-volume repair shops. Heat guns, though faster, can lead to uneven heating, affecting the final finish of the vehicle’s surface, especially in complex auto detailing work.

This is where UV paint curing systems step in as a game-changer. By using ultraviolet light to cure paint, these systems offer a significantly quicker process compared to traditional methods. Not only does this reduce the time needed for fender repair, but it also ensures consistent and precise results, enhancing the overall quality of collision repair services. Additionally, UV curing minimizes the risk of imperfections, ensuring a seamless finish that meets high auto detailing standards.

The Advantages of UV Paint Curing Systems: Speed and Efficiency

The advantages of UV paint curing systems are undeniable when it comes to enhancing repair shop efficiency. These innovative technologies offer a significant speed boost compared to traditional drying methods, reducing the time required for vehicle restoration and tire services. By exposing painted surfaces to ultraviolet light, UV curing systems rapidly harden the paint, eliminating the need for lengthy waiting periods.

This rapid curing process translates into streamlined body shop services, allowing technicians to manage higher production volumes with reduced labor costs. Moreover, UV paint curing systems ensure consistent and repeatable results, minimizing rework and maximizing customer satisfaction. The efficiency gained from these systems contributes to better utilization of resources, making repair shops more competitive in the market.

Integrating UV Curing into Repair Shop Workflows for Optimal Results

Integrating UV paint curing systems into repair shop workflows revolutionizes auto body work and enhances overall efficiency. This advanced technology significantly reduces cure times compared to traditional drying methods, allowing shops to increase throughput and accommodate more vehicle repair services. By eliminating the need for lengthy waiting periods between coat applications, UV curing enables technicians to complete tasks promptly, ensuring faster turnaround times for customers.

Additionally, UV paint curing systems offer superior quality control. The consistent and precise curing process results in smoother finishes, reduced overspray, and minimal surface imperfections. This precision not only boosts the aesthetics of auto painting but also reduces the amount of rework required, further optimizing repair shop operations.

UV paint curing systems represent a significant leap forward in repair shop efficiency. By eliminating the time-consuming and unpredictable aspects of traditional drying methods, these systems offer unparalleled speed and precision. Integrating UV technology into existing workflows streamlines processes, reduces waste, and enhances customer satisfaction. With its ability to quickly cure paints to high standards, the UV paint curing system is not just a trend but a reliable, long-term solution for modern repair shops.