Frame machine repair is a specialized, critical process for restoring vehicles' structural integrity after collisions. Using advanced technology like computer-aided measurement systems and precise machinery, skilled technicians meticulously assess and realign frames to pre-accident specifications. This ensures optimal safety and performance upon return to the road, making it an essential service provided by top collision repair centers. Regular calibration and maintenance of frame machines are vital for maintaining precision, upholding manufacturer standards, addressing residual dents or misalignments, and delivering high-quality repairs that guarantee customer satisfaction and vehicle safety.

Frame machine repair is a critical process in automotive body shops, ensuring precision and accuracy in collision repairs. This article delves into the intricate relationship between frame machines and collision outcomes. We explore how these specialized tools, through meticulous adjustment and alignment, directly influence the overall accuracy of collision repairs. By understanding the core repair process and implementing best practices, technicians can maintain optimal precision, delivering superior vehicle restoration results.

- Understanding Frame Machine Repair: The Core Process

- Impact on Collision Accuracy: Factors to Consider

- Best Practices for Maintaining Precision After Repairs

Understanding Frame Machine Repair: The Core Process

Frame machine repair is a specialized process that involves the precise adjustment and realignment of a vehicle’s frame after a collision or damage. It’s a critical step in the auto collision repair process, focusing on restoring structural integrity and ensuring the car handles correctly post-repair. The core process includes several steps: first, the damaged frame is carefully assessed to identify areas of distortion or misalignment. Then, using advanced technology like computer-aided measurement systems, technicians pinpoint exact adjustments needed.

Once the analysis is complete, specialized machinery is employed to make precise cuts and realignments, returning the frame to its original specifications. This meticulous approach guarantees that the vehicle’s structural components are brought back to their pre-accident condition, ensuring optimal safety and performance when returned to the road. It’s a critical service provided by top-tier collision repair centers, specializing in getting cars back on track—both literally and metaphorically—after they’ve encountered an accident.

Impact on Collision Accuracy: Factors to Consider

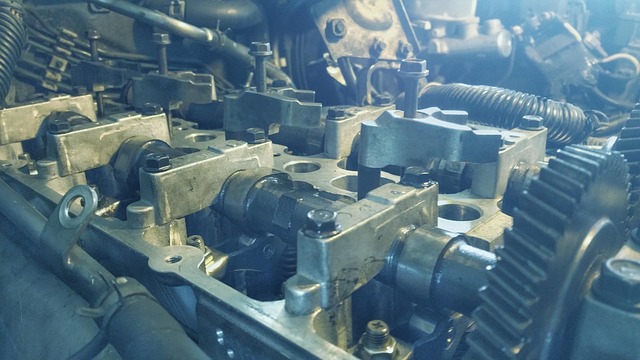

The accuracy of collision repairs heavily relies on the condition and alignment of a vehicle’s frame, which is why frame machine repair plays a pivotal role in achieving precise outcomes. When a car undergoes a collision, its frame can experience distortion or misalignment, leading to issues with fitment and structural integrity. A skilled technician employing advanced frame machine repair techniques ensures that these imperfections are rectified, allowing for accurate restoration of the vehicle’s original shape and safety standards.

Several factors contribute to the impact on collision accuracy during frame machine repair. The expertise and experience of the technicians involved are paramount. They must possess the knowledge to identify subtle frame shifts and correctly apply pressure and adjustments using specialized equipment. Additionally, the availability and quality of frame machines themselves are essential. Modern collision repair shops often invest in cutting-edge frame machines that offer precise measurements and dynamic adjustments, enabling them to deliver top-notch vehicle dent repair and restore cars to their pre-accident conditions, as seen in a reputable car body shop.

Best Practices for Maintaining Precision After Repairs

Maintaining precision after frame machine repairs is paramount to ensuring collision accuracy and top-notch car body shop services. Following best practices guarantees that the vehicle’s structural integrity is fully restored, aligning with original manufacturer standards. This begins with meticulous inspection of all repaired areas, utilizing advanced technology for precise measurements. Any residual dents or misalignments must be meticulously addressed through techniques like dent removal to achieve a seamless finish.

Furthermore, regular calibration and maintenance of the frame machine itself are crucial. Just as in mercedes benz repair processes, consistent care ensures optimal performance and accuracy. This includes routine checks, adjustments, and updates to the machine’s settings based on industry standards and manufacturer recommendations. By adhering to these practices, car body shops can confidently deliver high-quality repairs, ensuring customer satisfaction and vehicle safety on the road.

Frame machine repair plays a pivotal role in enhancing collision accuracy. By understanding the core process, considering key factors, and implementing best practices, auto body shops can ensure precise repairs that restore vehicles to their pre-accident condition. Optimizing frame machine repair techniques is not just about technical proficiency; it’s a commitment to client satisfaction and safety on the road.