Urethane bumper parts are durable, impact-resistant, and flexible, making them ideal for car collision repair and custom restorations. They offer advantages over traditional alternatives in terms of compatibility, chemical resistance, extreme temperature tolerance, and lighter weight. Despite potentially higher initial costs, their longevity reduces the need for frequent repairs, saving money in the long term. Pricing varies based on design complexity, material quality, market demand, craftsmanship, brand reputation, and industry requirements.

“Curious about urethane bumper parts and their cost comparison to traditional materials? This article delves into the world of urethane, exploring its unique properties and advantages as a automotive component. We conduct a detailed cost analysis, comparing urethane bumpers with conventional alternatives, shedding light on price influences. Understanding these factors empowers car owners and manufacturers alike to make informed decisions regarding this game-changing material.”

- Understanding Urethane Bumper Parts: Properties and Advantages

- Cost Analysis: Comparing Urethane to Traditional Materials

- Factors Influencing the Price of Urethane Bumper Components

Understanding Urethane Bumper Parts: Properties and Advantages

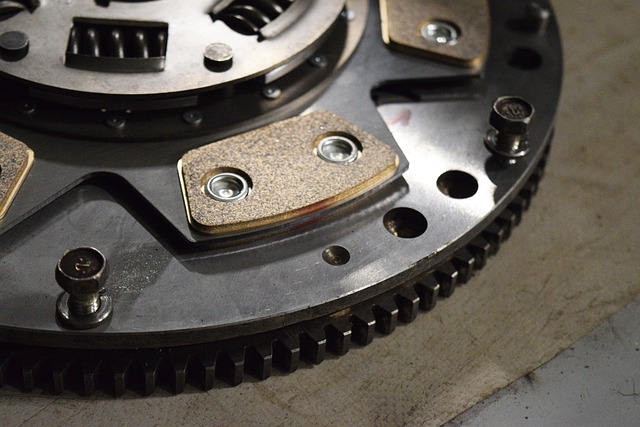

Urethane bumper parts stand out in the realm of automotive repairs and vehicle restoration due to their exceptional properties. This versatile material is known for its durability and impact resistance, making it a popular choice for car collision repair. Unlike traditional materials, urethane offers superior flexibility, allowing it to withstand significant force without cracking or breaking, which is crucial for maintaining the structural integrity of a vehicle’s bumper.

When it comes to auto repair shop considerations, urethane bumper parts offer a range of advantages. They are highly compatible with various surfaces, simplifying the installation process. Moreover, urethane’s ability to resist chemicals and extreme temperatures ensures longevity, even in demanding environments. This makes it an excellent option for both original equipment manufacturer (OEM) replacements and custom vehicle restoration projects, promising performance that matches or surpasses that of its metal counterparts while offering lighter weight and potentially lower costs.

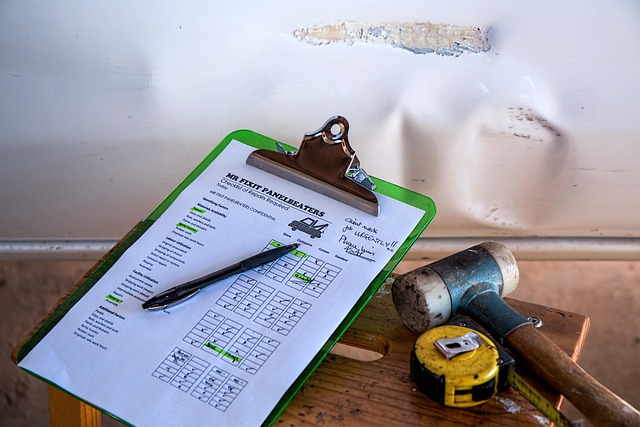

Cost Analysis: Comparing Urethane to Traditional Materials

When comparing the cost of urethane bumper parts to traditional materials like metal or plastic, several factors come into play. Initially, the price point of raw urethane may seem higher than that of conventional body shop services materials. However, this initial investment is often offset by the exceptional durability and long-term reliability of urethane bumper parts. In many cases, urethane components can withstand significant impact and damage without needing replacement, reducing the need for frequent frame straightening or other intensive automotive body shop repairs in the long run.

Moreover, the seamless integration of urethane bumper parts into modern vehicles’ designs offers advantages beyond cost. This material’s flexibility allows for more intricate and precise moldings, enhancing a vehicle’s aesthetic appeal. In contrast to simple plastic components, urethane can mimic the look and feel of original equipment, contributing to a smoother overall restoration process—all while potentially saving on materials and labor in dedicated automotive body shop settings.

Factors Influencing the Price of Urethane Bumper Components

The cost of urethane bumper parts is influenced by several key factors. Firstly, the complexity of the design plays a significant role; intricate patterns or custom shapes will generally command higher prices due to the specialized manufacturing processes required. Secondly, material quality is critical; higher-grade urethane offers superior durability and performance but comes at a premium compared to more basic options. Additionally, the market demand for specific urethane bumper parts can impact pricing, with rare or high-demand items typically costing more.

Other considerations include the level of craftsmanship involved in the production process and the overall brand reputation of the manufacturer. Given that urethane is a versatile material used not only in auto body painting and vehicle repair services but also in tire services and various industrial applications, price disparities can arise based on end-use industry requirements and the added value of after-sales support or warranties.

When considering urethane bumper parts, a comprehensive understanding of their cost compared to alternative materials is essential. The analysis reveals that while initial investment in urethane may be higher, its durability and unique properties offer long-term benefits. By factoring in the reduced need for frequent replacements and superior performance, urethane emerges as a compelling choice for those seeking reliable and cost-effective bumper solutions.