Aluminum body components, favored for their strength-to-weight ratio, corrosion resistance, and malleability, are transforming structural frame repairs in automotive applications. They offer a cost-effective alternative to carbon fiber while enabling advanced techniques like paintless dent repair. Integrating aluminum with carbon fiber components, a powerful combination known for enhanced structural integrity and aesthetic appeal, is a game-changer in vehicle restoration. For optimal results, a strategic approach involving damage assessment, suitable alloy selection, best practices in welding and forming, and the strategic incorporation of carbon fiber for added rigidity is crucial.

Aluminum body components offer a revolutionary approach to structural frame repairs, providing lightweight yet robust solutions. This article explores the advantages and diverse applications of aluminum in construction, with a focus on its synergistic pairing with carbon fiber components. We delve into effective implementation strategies, best practices, and real-world case studies, highlighting how this powerful combination enhances durability, reduces weight, and optimizes structural integrity for various repair scenarios. Discover why integrating these advanced materials is a game-changer in the industry.

- Understanding Aluminum Body Components: Advantages and Applications in Structural Repairs

- Integrating Carbon Fiber into Aluminum Frame Repairs: A Powerful Combination

- Implementation Strategies and Best Practices for Effective Aluminum Body Component Use in Structural Frame Repairs

Understanding Aluminum Body Components: Advantages and Applications in Structural Repairs

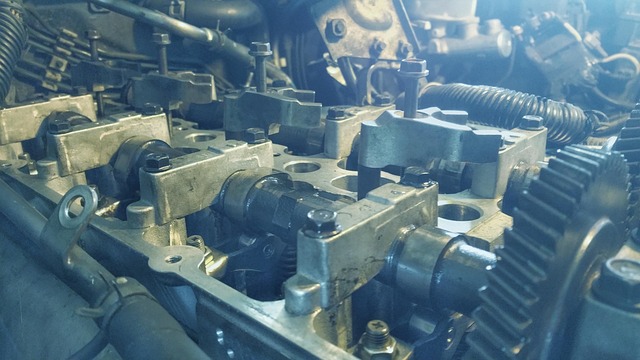

Aluminum body components have emerged as a preferred choice for structural frame repairs due to their exceptional properties. These lightweight materials offer superior strength-to-weight ratios, making them ideal for enhancing vehicle safety and performance. In car body repair and bodywork applications, aluminum is renowned for its corrosion resistance, which is particularly beneficial in regions with harsh climates or high humidity levels. Its malleability allows for precise fabrication, enabling complex designs and seamless integration into various vehicle structures.

When compared to traditional carbon fiber components, aluminum provides a cost-effective solution without compromising on quality. It facilitates advanced techniques like paintless dent repair, ensuring minimal impact on the overall aesthetics of the car bodywork. This versatility makes aluminum a go-to material for both structural repairs and cosmetic enhancements, catering to diverse automotive needs.

Integrating Carbon Fiber into Aluminum Frame Repairs: A Powerful Combination

Integrating carbon fiber components into aluminum frame repairs represents a powerful combination that’s transforming the automotive industry. Carbon fiber’s exceptional strength-to-weight ratio complements aluminum’s natural durability and corrosion resistance, offering a superior solution for structural frame repairs in auto body shops. This innovative approach not only enhances the structural integrity of vehicles but also contributes to their overall aesthetic appeal.

In vehicle restoration projects, combining carbon fiber and aluminum allows for precise, intricate repairs while maintaining the original car’s sleek lines. Auto body services that embrace this technology can deliver top-notch results, ensuring vehicles not only drive better but also look as good as new. By leveraging these advanced materials, professionals in the field are revolutionizing what’s possible in frame restoration and setting new standards for quality and performance.

Implementation Strategies and Best Practices for Effective Aluminum Body Component Use in Structural Frame Repairs

When integrating aluminum body components into structural frame repairs, a strategic approach is essential for optimal results. Begin by assessing the vehicle’s damage and identifying areas suitable for aluminum replacement. This involves careful measurement and visualization to ensure accurate fitting. Next, choose the right aluminum alloys tailored to automotive applications, prioritizing those that offer excellent corrosion resistance and strength-to-weight ratio.

Implementing best practices ensures successful integration. These include proper welding techniques to maintain structural integrity and utilizing specialized tools for precise cutting and forming. For complex repairs, consider employing frame straightening technologies to realign the vehicle’s frame accurately. Additionally, carbon fiber components can be strategically incorporated for enhanced rigidity and weight reduction, further improving the overall performance and efficiency of the vehicle repair process in auto collision centers.

Aluminum body components, with their superior strength-to-weight ratio and corrosion resistance, are a game-changer in structural frame repairs. When combined with carbon fiber components, these materials offer an even more robust solution, enhancing structural integrity and durability. By adopting best practices and strategies for integration, professionals can effectively leverage this powerful combination to deliver high-quality repairs, ensuring longevity and performance across various applications.