Anti-Flutter Foam is a lightweight yet robust material that protects aluminum body panels from shock, flutter marks, and dents, preserving car aesthetics and reducing repair costs. Its innovative design enhances durability, prevents rust, and streamlines painting processes. Best practices for maintaining anti-flutter foam repairs include regular inspections, prompt damage addressing, professional services, and protective coatings. This revolutionary material is ideal for both professionals and DIY enthusiasts seeking efficient, high-quality auto body repairs.

Aluminum body panels, known for their lightweight and durability, face unique challenges from corrosion and flutter damage. This is where Anti-Flutter Foam (афф) steps in as a revolutionary solution. This article delves into the world of aff, exploring its crucial role in protecting aluminum panels and why it makes an excellent anti-flutter foam replacement. We’ll dissect its benefits, detailed application process, and best practices for ensuring longevity.

- Understanding Anti-Flutter Foam and Its Role in Aluminum Panel Protection

- The Benefits of Using Anti-Flutter Foam as a Replacement

- Application Process and Best Practices for Longevity

Understanding Anti-Flutter Foam and Its Role in Aluminum Panel Protection

Anti-Flutter Foam is a specialized protective material designed to prevent aluminum body panels from developing unsightly flutter marks or dents after impact. This foam acts as a shock absorber, redistributing energy during auto collisions or accidental bumps, ensuring that the metal surface remains intact and free from damage. Its crucial role in automotive maintenance, particularly at auto collision centers, is to provide an effective yet subtle barrier between external forces and the delicate structure of aluminum panels.

By serving as a lightweight yet robust layer, anti-flutter foam replacement offers a cost-efficient solution for auto repair services aiming to preserve car bodywork services’ aesthetic value. This innovative material is especially valuable for vehicle owners who want to maintain their aluminum-bodied cars in top condition, preventing potential damage from everyday incidents and ensuring the panels’ longevity without requiring frequent replacements.

The Benefits of Using Anti-Flutter Foam as a Replacement

Anti-Flutter Foam offers numerous advantages as a replacement for traditional methods in aluminum body panel repairs. One of its key benefits is the ability to provide a more durable and long-lasting fix, ensuring the structural integrity of the vehicle’s panels. This foam is designed to create a seamless bond with metal surfaces, effectively filling and sealing any gaps or damage, which significantly reduces the risk of future rusting and corrosion.

Unlike some auto repair services that may require multiple layers of paint to conceal repairs, Anti-Flutter Foam creates a smooth base, ready for auto body painting. This not only streamlines the repair process but also results in a more aesthetically pleasing finish, making it an ideal solution for those seeking high-quality car paint repair without the hassle. Its versatility and effectiveness make it a game-changer in the world of auto body repairs, catering to both professional mechanics and DIY enthusiasts looking for efficient solutions.

Application Process and Best Practices for Longevity

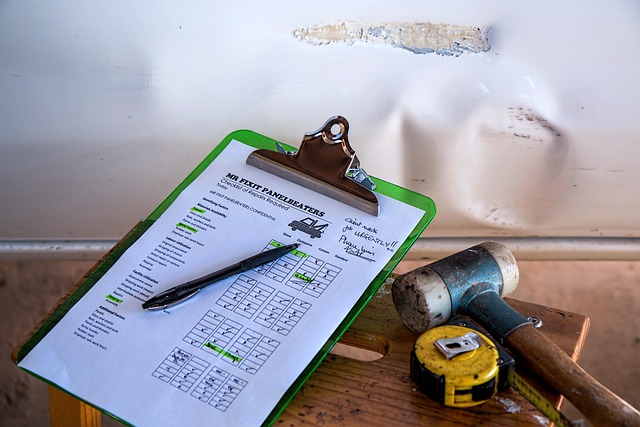

The application process of anti-flutter foam for aluminum body panels involves several precise steps to ensure optimal results and longevity. It begins with thorough preparation of the panel surface, including cleaning and de-greasing to remove any contaminants that could hinder adhesion. A primer is then applied to create a bond between the metal and the foam, enhancing durability. The foam itself is carefully rolled or sprayed onto the primed panel, ensuring even coverage without gaps or overlaps. Once set, a final top coat is added for protection against environmental factors, enhancing the overall aesthetics and extending the lifespan of the repair.

Best practices for longevity include regular inspection and maintenance. After installation, it’s crucial to monitor for signs of damage, moisture intrusion, or foam degradation. Repairs should be addressed promptly through professional car paint services or body shop services, as neglecting these issues can compromise structural integrity. Auto dent repair techniques may also be required over time to minimize dings and dents that could impact the foam’s performance. Regular cleaning and protection with wax or polymer coatings further safeguard against UV damage and road grime, ensuring the anti-flutter foam replacement remains effective for years to come.

Anti-Flutter Foam emerges as an innovative solution for protecting aluminum body panels, offering significant advantages over traditional methods. By acting as a robust barrier, this foam replacement enhances the structural integrity and aesthetic appeal of aluminum surfaces. Its application process, when followed diligently, ensures longevity, making it a reliable choice for automotive, maritime, and construction industries seeking superior panel protection. Adopting Anti-Flutter Foam is not just about enhancing durability; it’s about embracing a cutting-edge technology that redefines the standard for aluminum panel care.