Auto repair shops face challenges with hazardous materials, heavy machinery, and diverse tasks, posing risks like physical injuries, toxic exposure, and accidents. Adequate technician safety equipment is crucial for protecting skilled professionals from these dangers, enhancing worker protection and operational efficiency. Prioritizing technician safety improves shop reputation, attracts talent, and builds customer trust, while implementing best practices, regular maintenance, and training fosters a proactive safety culture.

In the high-energy environment of auto repair shops, where risks are ever-present, ensuring the safety of technicians is paramount. This article explores why technician safety equipment is essential in these dynamic workplaces. We delve into the unique hazards faced by automotive professionals and how specialized gear plays a vital role in mitigating them. By understanding these risks and implementing best practices, shops can foster a culture of safety, enhancing not just the well-being of their technicians but also the overall efficiency and reputation of the business.

- Understanding the Risks in Auto Repair Shops

- The Role of Technician Safety Equipment

- Benefits and Best Practices for Implementation

Understanding the Risks in Auto Repair Shops

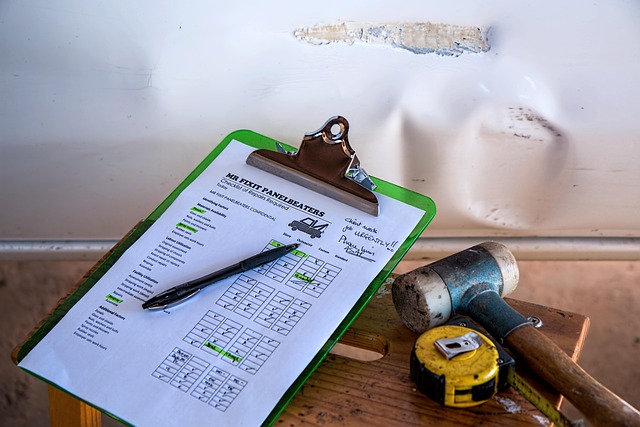

Auto repair shops are far from ordinary work environments; they present a unique set of challenges and risks for technicians. From handling hazardous materials to working with heavy machinery and powerful tools, every task has its potential dangers. The diverse nature of auto repair services means that technicians often encounter various situations, including vehicle bodywork repairs, painting, and even collision center operations, each requiring specific safety measures.

These risks can range from serious physical injuries to exposure to toxic substances. For instance, working on a vehicle’s engine or exhaust system may involve hazardous fumes, while certain repair processes require the use of powerful chemicals. Additionally, many tasks involve heavy lifting and operating equipment that demands focus and proper training to prevent accidents. Therefore, ensuring technician safety equipment is paramount in creating a secure workplace environment for these skilled professionals.

The Role of Technician Safety Equipment

In the high-pressure environment of auto repair shops, technician safety equipment plays a pivotal role in safeguarding workers and ensuring efficient operations. With tasks ranging from intricate mechanical repairs to hazardous tasks like handling toxic fluids or operating heavy machinery, proper protective gear is not just a recommendation but a necessity. This equipment acts as a crucial barrier between technicians and potential risks, enabling them to perform their duties with confidence and minimal exposure to dangers.

The significance of technician safety equipment extends beyond individual protection; it significantly contributes to the overall quality and reputation of auto repair services. By prioritizing worker safety, repair shops foster an environment that attracts skilled professionals and promotes customer trust. This is particularly vital in the competitive automotive industry, where customers are increasingly conscious of both the quality of auto body services and the safety protocols employed by service providers.

Benefits and Best Practices for Implementation

Implementing technician safety equipment offers numerous benefits for auto repair shops, significantly enhancing the workplace environment and overall efficiency. Well-equipped technicians are better protected against potential hazards common in car body shop environments, from sharp metal shards to toxic fumes from car paint services processes. This reduces the risk of injuries and health issues, leading to higher employee morale, reduced absenteeism, and a positive safety culture.

Best practices for integrating technician safety equipment involve creating a comprehensive assessment of risks specific to each work area within the collision center. Prioritize essential gear based on these assessments, ensuring all staff receive adequate training in its proper use. Regular maintenance and inspections are crucial to keep equipment in optimal condition, fostering a proactive approach to safety that benefits both technicians and the reputation of the car paint services department as a whole.

In light of the above discussions, it’s clear that technician safety equipment is not just a recommendation but an essential aspect of auto repair shops. By equipping technicians with the right gear, shops can significantly reduce risks, enhance workplace safety, and foster a culture of care and responsibility. Implementing best practices for technician safety equipment usage should be a top priority for all automotive businesses to ensure a safer environment for their employees and better outcomes for customer vehicles.