Ultrasonic thickness gauges are advanced tools that measure material thickness non-destructively using ultrasonic waves, vital in industries like automotive repair for precision and structural integrity. Effective utilisation requires comprehensive training covering measurement principles, sound wave utilisation, and diverse material properties. Safety protocols, regular maintenance including calibration checks and cleaning, prevent damage or malfunction, ensuring reliable measurements for informed decision-making in vehicle repairs.

“Unleash the full potential of your work with comprehensive training on ultrasonic thickness gauges. This guide provides an in-depth look at the essential skills needed for accurate and safe operation. From understanding the fundamentals and advanced principles to step-by-step usage, you’ll master every aspect. Learn best practices for safety and maintenance to ensure consistent, reliable results. Discover how regular training can revolutionize your measurements and make ultrasonic thickness gauges a versatile tool in any industry.”

- Understanding Ultrasonic Thickness Gauges: Basics and Principles

- Step-by-Step Training for Effective Gauge Usage

- Safety and Maintenance: Ensuring Accurate Measurements with Continuous Training

Understanding Ultrasonic Thickness Gauges: Basics and Principles

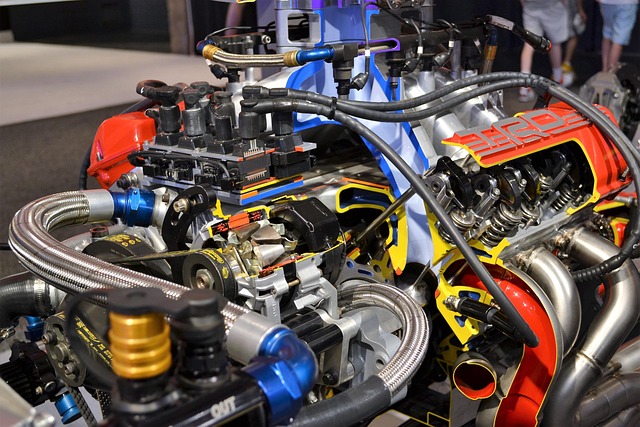

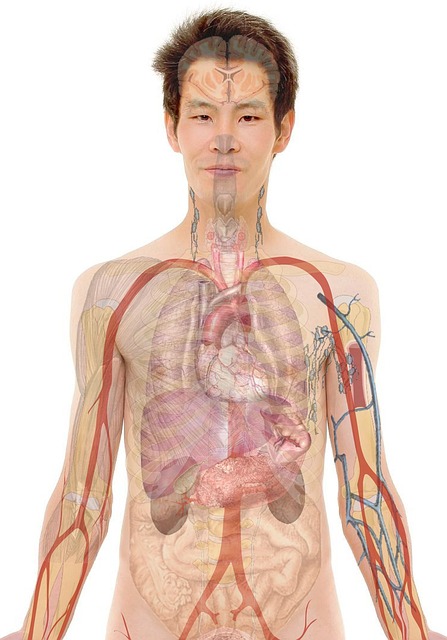

Ultrasonic thickness gauges are advanced measurement tools used to determine the thickness of materials, especially in industries like automotive and vehicle body shops where precision is paramount. These devices operate on the principle of transmitting ultrasonic waves through a material and measuring the time it takes for the waves to return, thereby calculating thickness based on the speed of sound. This non-destructive testing method ensures that the integrity of the material’s structure remains unaltered during inspection.

Understanding how these gauges function requires knowledge of basic physics concepts, including the speed of sound in different materials and the principles of wave propagation. In a collision repair or auto body shop setting, ultrasonic thickness gauges are invaluable for quality control, ensuring that repairs maintain the structural integrity of vehicle bodies. This technology plays a significant role in achieving accurate results during the rebuilding process, making it an essential tool for professionals in these industries.

Step-by-Step Training for Effective Gauge Usage

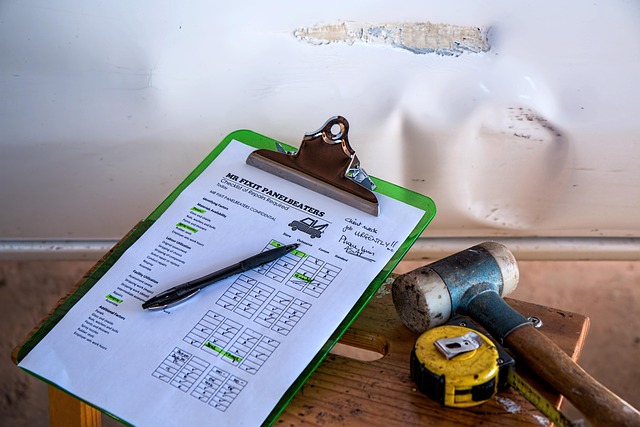

Proper training is essential for anyone looking to utilise an ultrasonic thickness gauge effectively, especially in industries such as car damage repair and collision repair where precision is paramount. The process should begin with a comprehensive introduction to the principles behind ultrasonic measurements, including an explanation of how sound waves are utilised to determine material thickness.

A step-by-step training programme could include hands-on practice sessions where individuals learn to operate the gauge, ensuring they understand the various controls and settings. This would involve demonstrating how to select the appropriate frequency, apply the transducer correctly, and interpret the displayed measurements. Additionally, training should cover different materials and their unique properties, helping technicians adapt their approach for optimal results in auto body painting or any other application.

Safety and Maintenance: Ensuring Accurate Measurements with Continuous Training

Proper safety protocols and regular maintenance are paramount for accurate measurements with ultrasonic thickness gauges. Continuous training ensures that users understand the device’s functions, limitations, and potential hazards. This includes knowing how to operate the gauge correctly, interpret results accurately, and maintain its components to prevent damage or malfunction. Regular calibration checks and cleaning routines are essential, especially in environments where contaminants could impact readings, such as in car damage repair or vehicle paint repair workshops.

By adhering to safety guidelines and maintaining their ultrasonic thickness gauges, technicians can ensure reliable measurements for various vehicle repairs, including body panels, paint jobs, and structural integrity assessments. Proper training equips them with the skills to make informed decisions based on accurate data, thereby enhancing the quality of car damage repair and vehicle paint repair services.

Proper training is essential for ensuring accurate and reliable measurements using ultrasonic thickness gauges. By understanding the fundamentals, following step-by-step guidelines, and prioritizing safety and maintenance, users can leverage these powerful tools to their full potential. Continuous education and practice are key to maximizing the benefits of ultrasonic thickness gauges in various industries, ensuring consistent quality control and enhanced productivity.