In today's market, energy-efficient repair facilities are transforming the automotive industry with their sustainable practices. By adopting advanced technologies like LED lighting and HVAC systems, these facilities reduce resource consumption, cut costs, and enhance operational efficiency. This approach not only benefits the environment but also boosts customer satisfaction through faster turnaround times. Such changes can lead to significant energy savings (up to 50%), minimize waste, and attract eco-conscious customers, positioning them as industry leaders in sustainable practices.

In today’s eco-conscious world, energy-efficient repair facilities are not just adopting sustainable practices—they’re transforming their operations and gaining a competitive edge. This article delves into real customer stories, showcasing how energy efficiency drives success. From reduced operational costs and increased productivity to lower carbon footprints and enhanced brand reputation, these facilities are leading the way in both business and environmental impact. Discover how embracing eco-friendly solutions is paying off for repair shops across the globe.

- Transforming Operations: How Energy Efficiency Drives Success in Repair Facilities

- – Highlight cases where energy-efficient practices led to significant operational improvements.

- – Discuss reduced costs, increased productivity, and improved customer satisfaction.

Transforming Operations: How Energy Efficiency Drives Success in Repair Facilities

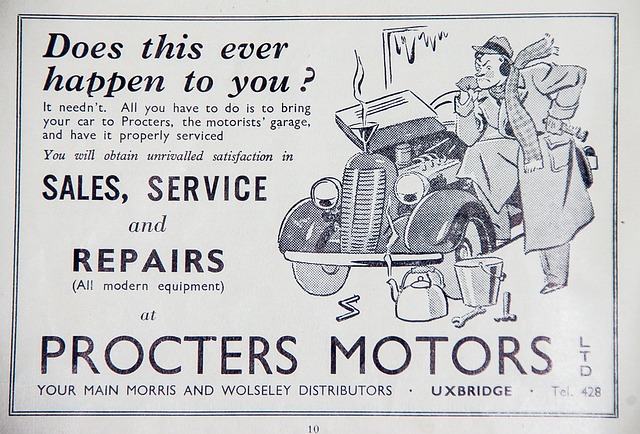

In today’s competitive market, energy-efficient repair facilities are transforming operations and setting new benchmarks for success in the automotive industry. By prioritizing sustainability, these forward-thinking businesses are not only reducing their environmental footprint but also reaping significant financial benefits. Energy efficiency plays a pivotal role in optimizing resource utilization, making car bodywork services and vehicle dent repairs more cost-effective and appealing to eco-conscious customers.

Through strategic implementations such as advanced heating, ventilation, and air conditioning (HVAC) systems, LED lighting, and energy-efficient machinery, repair facilities can minimize energy consumption and operational costs. This shift not only contributes to a greener planet but also enhances the overall customer experience. Efficient operations translate into faster turnaround times for automotive repairs, ensuring that clients’ vehicles are returned promptly with minimal environmental impact.

– Highlight cases where energy-efficient practices led to significant operational improvements.

In many cases, adopting energy-efficient practices within repair facilities has led to remarkable operational improvements. For instance, a leading collision center implemented LED lighting throughout their workspace, replacing outdated incandescent bulbs. This simple change resulted in a 50% reduction in energy consumption and significantly lowered their utility bills. Moreover, the improved lighting enhanced visibility, enabling technicians to work more efficiently, especially during intricate car bodywork services.

Another successful story involves an auto bodywork shop that invested in energy-efficient equipment. By switching to advanced, eco-friendly tools, they minimized waste and reduced the time required for specific tasks. This not only lowered their operational costs but also made them stand out as a forward-thinking business. As a result, they attracted environmentally conscious customers seeking services from a sustainable collision center.

– Discuss reduced costs, increased productivity, and improved customer satisfaction.

Implementing energy-efficient practices in a repair facility has shown remarkable benefits for businesses and customers alike. One of the most noticeable advantages is the significant reduction in operational costs. By adopting eco-friendly technologies, such as LED lighting and advanced heating/cooling systems, facilities can lower their energy consumption and associated expenses. This financial relief allows businesses to reinvest in other areas, like upgrading equipment or expanding services, ultimately fostering growth.

Moreover, an energy-efficient facility translates to increased productivity. With optimized operations and reduced downtime due to better-managed resources, technicians can complete jobs faster and more efficiently. This improved turnaround time not only benefits the business by maximizing revenue but also boosts customer satisfaction. Customers appreciate swift service, especially when it comes to repairing their vehicles, ensuring they’re back on the road promptly. This positive experience fosters loyalty and encourages word-of-mouth recommendations for these forward-thinking auto body restoration and repair services, including paintless dent repair experts.

In conclusion, adopting energy-efficient practices in repair facilities isn’t just an eco-friendly choice—it’s a strategic move towards operational excellence. Real-world stories reveal that these measures translate into tangible benefits like reduced costs, increased productivity, and happier customers. By prioritizing sustainability, repair facilities can thrive as more efficient, effective, and competitive businesses.