Advanced technology has revolutionized car crash repair services, boosting efficiency, precision, and customer satisfaction. Tools like CAD systems, 3D imaging, laser scanning, automated welding, and advanced materials streamline repairs, ensure accurate paint matching, and reduce restoration time. Laser-based auto glass repair and innovative techniques such as laser scanning and 3D printing further enhance the industry, allowing for faster, more tailored vehicle restorations.

In the realm of car crash repair services, advanced tools are revolutionizing the way technicians address vehicle damage. From state-of-the-art technology like laser scanning and 3D printing for custom parts, to sophisticated safety features that impact repair complexity, digital solutions enhancing efficiency and precision – the modern automotive repair landscape is dynamic and evolving.

This article delves into these innovative tools, shedding light on how they contribute to safer, more effective car crash repairs in today’s world.

- State-of-the-Art Technology in Car Crash Repair

- – Overview of modern tools and their benefits

- – Examples: Laser scanning, 3D printing for custom parts

State-of-the-Art Technology in Car Crash Repair

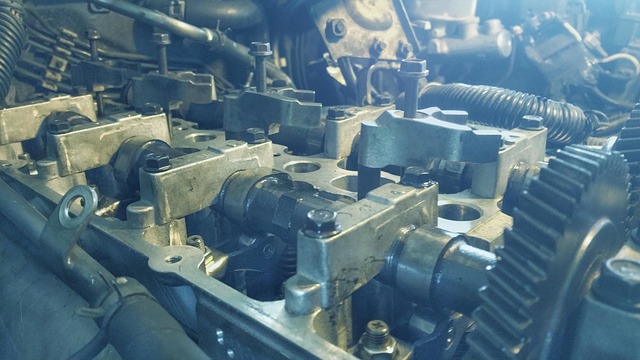

In the realm of car crash repair services, state-of-the-art technology plays a pivotal role in enhancing efficiency and precision. Modern auto bodywork shops are equipped with advanced tools that have revolutionized the way accidents are addressed. These technologies include sophisticated computer-aided design (CAD) systems, which enable technicians to create precise measurements and simulations of vehicle damage. By integrating 3D imaging and laser scanning, repair teams can meticulously map out the impact zones, ensuring every detail is accounted for during the restoration process.

Moreover, automated welding machines and robotic systems streamline the auto body work, promoting accuracy and reducing manual labor. In addition to these innovations, advanced materials are now commonly used, offering superior strength and durability while minimizing weight. This not only enhances vehicle safety but also contributes to more efficient repairs. Auto glass repair technologies have also seen significant advancements, with laser-based systems providing precise cuts and seamless installations, further enhancing the overall car crash repair service experience.

– Overview of modern tools and their benefits

Modern tools have revolutionized the car crash repair service industry, offering faster and more precise results than ever before. These advanced technologies are transforming auto body restoration processes, ensuring that damaged vehicles can be brought back to their pre-accident condition. From laser measurement systems to robotic welding equipment, these innovations enhance accuracy and efficiency in every stage of repair.

The benefits of using modern tools extend beyond just speedier repairs. They also improve the overall quality of auto body painting and auto detailing work. With sophisticated software and specialized equipment, technicians can now match paint colors precisely, ensuring a seamless finish. Moreover, advanced detailing tools allow for meticulous cleaning and polishing, restoring vehicles to their original gleam. These advancements not only benefit repair shops but also guarantee higher customer satisfaction in car crash repair service procedures.

– Examples: Laser scanning, 3D printing for custom parts

In today’s advanced automotive industry, car crash repair service has evolved significantly, incorporating cutting-edge tools and technologies that ensure better outcomes and faster turnaround times. One such innovation is laser scanning, a precise method used to capture detailed 3D images of damaged vehicles. This technology enables auto collision centers to meticulously assess the extent of damage, facilitating accurate repairs tailored to each unique case. By generating comprehensive digital models, technicians can identify even the subtlest discrepancies, ensuring every part is replaced or repaired correctly.

Furthermore, 3D printing has emerged as a game-changer in car crash repair service. This advanced manufacturing process allows for the creation of custom parts with remarkable accuracy and speed. Whether it’s replacing a damaged fender, door panel, or even complex interior components, 3D printing offers a cost-effective solution without compromising quality. As a result, auto maintenance becomes more efficient, and vehicles can be restored to their pre-accident condition in less time, benefiting both repair shops and vehicle owners alike.

In the realm of car crash repair services, embracing advanced tools isn’t just an option—it’s a game-changer. Modern technology, such as laser scanning and 3D printing, streamlines the process, enhances precision, and ensures that vehicles return to their pre-accident condition. These innovative solutions not only expedite repairs but also foster a more efficient and effective car crash repair service ecosystem. By integrating these state-of-the-art tools, repair shops can deliver top-notch results, satisfying both vehicle owners and insurance providers alike.