A bumper repair kit provides a convenient and efficient solution for restoring damaged car bumpers, offering an alternative to traditional body shop services. These kits include specialized components for achieving durable, aesthetically pleasing results that maintain vehicle integrity. The crucial curing process, dependent on temperature, humidity, and product type, ensures optimal strength and durability. Proper curing conditions, including a well-ventilated area and controlled temperatures, are essential for maximizing the effectiveness of bumper repair kits.

A damaged bumper can significantly impact a vehicle’s aesthetics and performance. Understanding the science behind bumper repair kits is crucial for optimal results. This article delves into the essential components of these kits and why their proper curing time is key to long-lasting repairs. We explore the chemistry behind the process, highlighting the factors affecting curing time and providing tips to ensure peak performance when using bumper repair kits.

- Understanding Bumper Repair Kit Components and Their Role

- The Science Behind Curing Time: Why It Matters

- Optimizing Curing Conditions for Best Results with Bumper Repair Kits

Understanding Bumper Repair Kit Components and Their Role

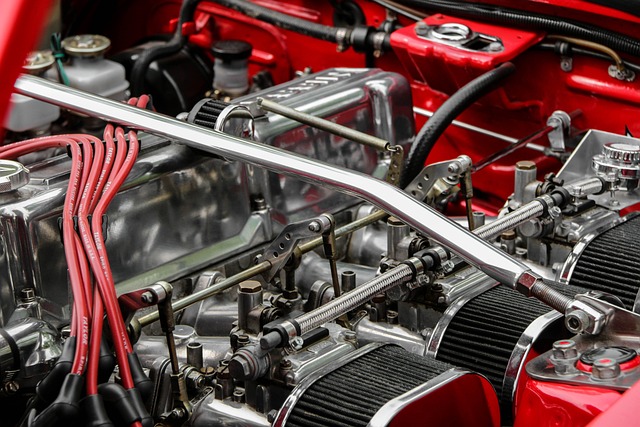

A bumper repair kit is a comprehensive solution designed to restore damaged car bumpers, offering an efficient alternative to traditional body shop services. These kits typically include various components, each playing a crucial role in the repair process. One of the key elements is the filler material, which serves as the base for rebuilding the bumper’s shape. This filler is often accompanied by a hardening agent that, when mixed and applied correctly, ensures precise shaping and long-lasting durability.

Additionally, the kit may contain primers and paints tailored to match the vehicle’s original color, ensuring a seamless finish after curing. The curing process, which varies based on product instructions, is vital for achieving optimal performance. Auto repair services often rely on this method as it allows for quick repairs while maintaining the aesthetic integrity of the car, making it an attractive option for both professional body shop services and DIY enthusiasts looking to restore their vehicles to like-new conditions.

The Science Behind Curing Time: Why It Matters

The science behind curing time is a critical aspect often overlooked when using a bumper repair kit. When you apply a repair compound or paint to damaged car bodywork, including bumpers, the material needs time to set and harden properly. This process, known as curing, allows the repair to achieve maximum strength and durability. The right curing time ensures that the molecules in the repair product have sufficient time to interlink and form a strong bond with the existing surface.

In the world of auto repair services and car bodywork services, a bumper repair kit’s effectiveness is directly tied to its curing properties. Curing times can vary depending on factors like temperature, humidity, and the specific product used. Most kits come with recommended time frames, which should be strictly adhered to by professionals or enthusiasts using these kits. Following the manufacturer’s guidelines ensures that your bumper looks as good as new while maintaining structural integrity—a key aspect that distinguishes a quality auto repair shop from its competitors.

Optimizing Curing Conditions for Best Results with Bumper Repair Kits

To achieve optimal results with a bumper repair kit, it’s crucial to understand and optimize curing conditions. The right environment significantly impacts the effectiveness of the repair process. Firstly, ensure the work area is well-ventilated; this promotes proper chemical reaction and prevents any hazardous buildup during the curing stage. Secondly, maintain consistent temperature levels, typically between 50°F to 77°F (10°C to 25°C), as extreme heat or cold can hinder the kit’s performance.

Additionally, consider factors like surface preparation and humidity. A clean, dry surface free from debris ensures optimal adhesion. High humidity levels can delay curing, so it’s beneficial to work in areas with controlled moisture content. By attentively managing these variables, users can maximize the potential of their bumper repair kits, delivering top-tier auto frame repair or car bodywork services.

In summary, the performance of a bumper repair kit significantly relies on the precise adherence to curing time. Understanding the science behind this process is key to achieving optimal results. By optimizing curing conditions, including temperature and exposure duration, users can ensure that the repair kit effectively bonds with the vehicle’s surface, providing long-lasting durability. This attention to detail is essential for anyone looking to restore their bumper’s appearance using a bumper repair kit.