Direct Repair Program (DRP) evaluations are vital for luxury car brands like Mercedes-Benz, ensuring consistent, high-quality repairs. Standardized guidelines provide a framework for assessing repair facilities' performance, empowering customers to choose shops and driving industry improvement. Key steps in implementing DRP evaluations include setting clear criteria, using digital platforms, training staff, and facilitating data-driven decision-making for continuous enhancement of car body shop services.

Consistency is key when evaluating Direct Repair Programs (DRPs), ensuring their effectiveness, accuracy, and long-term success. This article explores how maintaining consistent evaluation methods improves DRP outcomes, from initial implementation to ongoing performance monitoring. We’ll delve into the fundamental concepts of DRP evaluations, uncover the benefits of consistency, and provide practical strategies for implementing uniform assessment practices. By adhering to these guidelines, stakeholders can optimize their DRP management, fostering better repair quality and customer satisfaction.

- Understanding Direct Repair Program (DRP) Evaluations: A Foundation for Consistency

- The Role of Consistency in Enhancing DRP Effectiveness and Accuracy

- Strategies to Implement Consistent DRP Evaluations: Tools and Best Practices

Understanding Direct Repair Program (DRP) Evaluations: A Foundation for Consistency

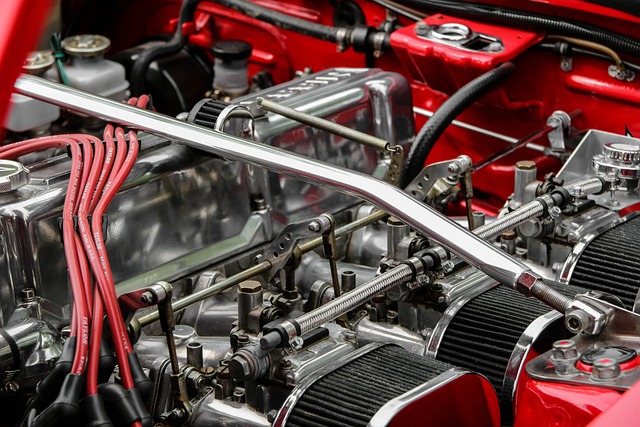

Direct Repair Program (DRP) evaluations are a crucial aspect of ensuring quality and consistency in automotive repairs, particularly for brands like Mercedes-Benz known for their meticulous craftsmanship. These evaluations serve as a foundational framework, providing standardized criteria to assess the performance of repair facilities. By implementing structured DRP guidelines, manufacturers can maintain control over the repair process, guaranteeing that cars meet their high standards, whether it’s for a simple car paint repair or complex mercedes benz repair.

The consistency in DRP evaluations is vital because it allows for fair comparisons between different repair shops. This standardization enables customers to make informed decisions when choosing a facility for their vehicle’s maintenance, ensuring they receive reliable and quality services. Moreover, consistent evaluations foster a culture of continuous improvement among repair centers, encouraging them to stay updated with the latest technologies and techniques in car damage repair.

The Role of Consistency in Enhancing DRP Effectiveness and Accuracy

Consistency plays a pivotal role in enhancing the effectiveness and accuracy of Direct Repair Programs (DRPs). When processes within a car body shop or vehicle repair facility are standardized and consistently executed, it leads to improved outcomes. This means that every aspect of a DRP, from initial assessments to final quality checks, follows a well-defined path. Such consistency ensures that repairs meet the required standards across all vehicles and among different technicians.

By maintaining consistent practices for car paint repair and other body work, the risk of errors and inconsistencies is significantly reduced. This uniformity benefits both customers and repair shops by guaranteeing high-quality workmanship. Moreover, it allows for better tracking and comparison of repair results over time, enabling DRP managers to identify areas for improvement and make data-driven decisions for future repairs in car body shops.

Strategies to Implement Consistent DRP Evaluations: Tools and Best Practices

Implementing consistent Direct Repair Program (DRP) evaluations is a multifaceted strategy that ensures fair and efficient assessments across all participating collision repair services. The first step involves establishing clear, standardized evaluation criteria. This includes defining measurable metrics for quality of workmanship, cost-effectiveness, and customer satisfaction within auto body repair processes. Utilizing industry-recognized standards and guidelines provides a robust foundation for these evaluations.

Next, leveraging the right tools is paramount. Digital assessment platforms offer an effective way to capture, record, and analyze data during DRP inspections. These platforms enable real-time communication between assessors and auto maintenance professionals, fostering transparency and accountability. Regular training sessions for repair shop staff on evaluation procedures and tools ensure everyone understands best practices, contributing to a uniform evaluation process across the board.

Consistency is a cornerstone in ensuring the effectiveness and accuracy of Direct Repair Program (DRP) evaluations. By adopting uniform methodologies, clear guidelines, and standardized metrics, organizations can significantly improve their DRP performance. Implementing consistent evaluations allows for fair comparisons between different repair facilities, fosters quality control, and ultimately enhances customer satisfaction. Embracing best practices and leveraging available tools can streamline the process, making consistency attainable and beneficial for all stakeholders involved in DRP management.