Advanced welding techniques, utilizing tools like laser welders, robotic arms, TIG and MIG welders, are crucial in modern auto repair and body restoration, ensuring precise, strong, and aesthetically pleasing joins. These methods cater to diverse vehicle structure needs, from intricate metal fabrication to straightforward repairs, elevating repair quality, efficiency, and ultimately, customer satisfaction.

“Unleash your auto repair expertise with our comprehensive guide to advanced welding techniques. Dive into a world where precision meets metal fusion, transforming everyday repairs into intricate art. From understanding the arsenal of specialized tools and safety protocols to mastering complex methods like TIG, MIG, and laser welding, this guide equips you with the knowledge to tackle challenging auto welds.

Explore troubleshooting secrets, common challenges, and expert tips for achieving unwavering, durable bonds—all tailored to the unique demands of automotive restoration.”

- Understanding Advanced Welding Techniques: Tools and Equipment

- – Overview of specialized tools for advanced welding

- – Types of welders used in auto repair for different techniques

Understanding Advanced Welding Techniques: Tools and Equipment

Advanced welding techniques are a crucial aspect of modern auto repair and car body restoration processes. These methods go beyond conventional welding, employing specialized tools and equipment to achieve precise, robust, and aesthetically pleasing joins in automotive body work. Professionals in the industry leverage advanced machines like laser welders, robotic arms, and TIG (Tungsten Inert Gas) welders for complex tasks that demand high accuracy and strength.

Understanding these techniques requires familiarity with a range of tools, from computer-aided welding systems to advanced safety gear. The automotive body shop environment must be equipped with state-of-the-art machinery capable of handling intricate patterns and tight tolerances, ensuring the final product is not just functional but also visually appealing. This comprehensive approach to auto body work elevates the quality of repairs, contributing to a longer-lasting and more attractive vehicle for customers.

– Overview of specialized tools for advanced welding

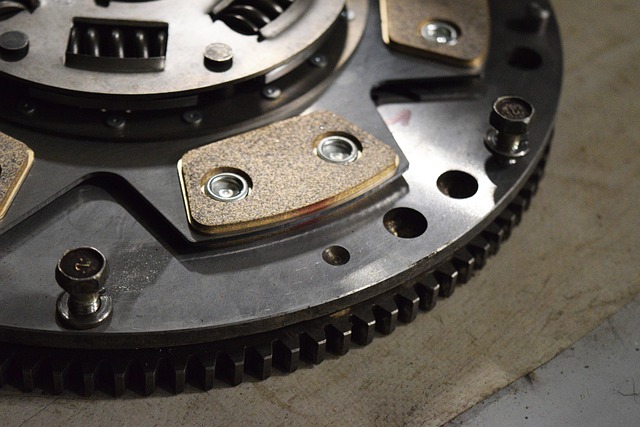

Specialized tools are a cornerstone of advanced welding techniques in auto repair. These tools are designed to enhance precision, efficiency, and strength in joining metal components, often found in complex vehicle structures like auto frame repair. From laser welders that offer unparalleled accuracy to robotic arms that ensure consistent bead patterns, each tool caters to specific needs. For instance, plasma cutters are indispensable for precise edge preparation before welding, while TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welders provide versatile solutions for a range of materials and applications, from joining metal panels in auto body painting to repairing intricate components.

The advancement in these tools allows auto repair shops to tackle sophisticated repairs with confidence. They enable technicians to perform tasks that were once time-consuming or challenging, ensuring superior results in auto frame repair, auto glass repair, and even auto body painting processes. As technology continues to evolve, these specialized tools will only become more crucial in the quest for flawless, durable repairs.

– Types of welders used in auto repair for different techniques

In an auto repair shop, the choice of welder is a critical factor determining the quality and efficiency of car body repair. For instance, advanced welding techniques like TIG (Tungsten Inert Gas) welding are ideal for intricate metal fabrication tasks, ensuring precise and clean cuts. This method is particularly popular in vehicle body shops that deal with precision restoration work due to its ability to join various metals without damaging their structural integrity.

On the other hand, MIG (Metal Inert Gas) welding, another advanced welding technique, offers speed and ease of use for more straightforward tasks. It’s a go-to method in many auto repair shops for quick, reliable, and cost-effective repairs. For heavier-duty applications, such as structural repairs or larger components replacement in car body repair, flux-core welding provides the necessary power and penetrance. This versatility ensures that vehicle body shops can handle a wide range of tasks efficiently and effectively.

Mastering advanced welding techniques is a game-changer for auto repair professionals, enabling them to deliver high-quality, durable repairs. By understanding the specialized tools and equipment required, such as TIG and MIG welders, along with their unique applications, technicians can confidently navigate complex repairs. These techniques not only enhance the precision of work but also ensure structural integrity in a variety of vehicle components. With the right knowledge and resources, auto repair shops can revolutionize their services, providing customers with superior craftsmanship and peace of mind.