The evolution of dent repair tools has significantly advanced thanks to technological innovations within the automotive industry, particularly automated and smart devices utilizing CAD, robotics, sensors, AI, 3D printing, and high-resolution cameras. These cutting-edge technologies streamline repairs, ensure consistent quality, precise color matching, and enhance customer satisfaction, accessible for both professionals and DIY enthusiasts alike.

Dent repair tools are evolving rapidly, keeping pace with modern car technologies. This transformation is driven by advanced digital innovation, automation, and 3D printing, enabling unprecedented precision in repairing car dents. The industry is also embracing eco-friendly solutions, incorporating sustainable materials like bioplastics and water-based formulas to meet growing environmental concerns. Furthermore, artificial intelligence (AI) is integrating into dent repair, promising enhanced efficiency and accuracy through damage assessment and predictive repair. These advancements are revolutionizing the dent repair landscape, ensuring faster, greener, and smarter repairs for modern vehicles.

- The Shift Towards Advanced Technology in Dent Repair Tools

- – Exploring the role of digital innovation and automation

- – The impact of 3D printing and smart sensors on dent repair precision

The Shift Towards Advanced Technology in Dent Repair Tools

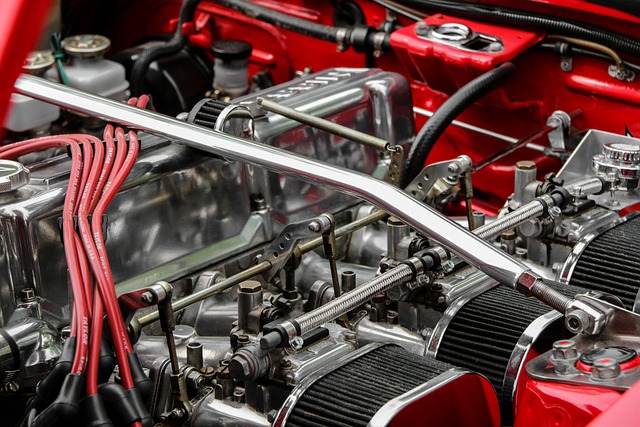

The evolution of dent repair tools mirrors the technological advancements that have transformed the automotive industry as a whole. Modern cars are increasingly equipped with complex systems and materials, necessitating sophisticated tools to match. This shift towards advanced technology in dent repair is evident in the development of innovative devices designed to handle intricate car body restoration tasks with precision and efficiency.

Automated and smart dent repair tools are emerging as game-changers in auto detailing and collision centers. These technologies leverage computer-aided design (CAD) and robotics to achieve seamless, near-perfect results. By using advanced sensors and algorithms, these tools can detect even the subtlest dents and dings, ensuring a more uniform and consistent repair across various car body surfaces. This technological edge not only streamlines the dent repair process but also enhances the overall quality of car body restoration.

– Exploring the role of digital innovation and automation

The evolution of dent repair tools is a direct reflection of digital innovation and automation transforming various industries, including automotive care. Modern car manufacturers are increasingly incorporating advanced technologies into their production processes, setting new standards for vehicle body repair precision and efficiency. Automated dent repair systems, for instance, use robotic arms and computer-aided design (CAD) software to precisely identify and rectify dents, offering a faster, more consistent alternative to manual methods.

These technological advancements extend beyond automated systems, with digital sensors and high-resolution cameras now integral to many dent repair tools. Such innovations enable detailed analysis of car paint repairs, ensuring precise color matching across vast vehicle surfaces. By leveraging artificial intelligence (AI) and machine learning, these tools can adapt to various car models, making auto body work more accessible and efficient for both professionals and DIY enthusiasts alike.

– The impact of 3D printing and smart sensors on dent repair precision

The evolution of dent repair tools has been significantly shaped by cutting-edge technologies like 3D printing and smart sensors. These innovations are transforming the way auto body restoration is performed, enhancing precision and efficiency in modern car repairs. 3D printing allows for the creation of custom, precise parts, reducing the need for time-consuming manual fabrication. This technology ensures that each repair is tailored to the exact specifications of the vehicle, resulting in a more seamless and structurally sound fix.

Smart sensors play a crucial role in achieving this precision by providing real-time data on damage. These sensors can detect even subtle dents or deformities, offering auto repair shops invaluable insights for accurate car body repair. By combining sensor data with 3D printing capabilities, technicians can now address complex dent repair tasks with greater speed and confidence, ultimately improving customer satisfaction in modern auto repair shops.

As we move forward, the evolution of dent repair tools driven by advanced technology promises to revolutionize car upkeep. Digital innovation, automation, 3D printing, and smart sensors are transforming the way dents are repaired, offering greater precision, efficiency, and accessibility. These developments not only enhance the quality of repairs but also make automotive care more convenient and cost-effective for modern vehicle owners.