Tesla repair scanning is a revolutionary diagnostic tool that uses advanced technology to thoroughly inspect Tesla vehicles, identifying everything from minor dents and sensor malfunctions to complex structural damage. By logging fault codes and critical data points, it enables accurate, efficient auto repairs tailored to each vehicle's unique needs. This process predicts and prevents significant issues, saving time, money, and enhancing customer satisfaction by ensuring optimal vehicle performance and safety.

“Uncovering the secrets of Tesla repair scanning, this article offers a comprehensive guide for automotive enthusiasts and professionals alike. We delve into the intricate process of pre-repair scanning, exploring what data is captured and how it empowers mechanics to predict potential issues. From identifying faulty components to preventing costly repairs, Tesla repair scanning is revolutionizing garage work. Learn about the critical information logged and flagged, enabling targeted diagnostics and efficient, effective vehicle restoration.”

- Understanding Tesla Repair Scanning: A Comprehensive Overview

- The Data Captured: What Information is Collected During Pre-Repair Scans

- Flagged Issues: Identifying and Addressing Potential Problems Before Repair

Understanding Tesla Repair Scanning: A Comprehensive Overview

Tesla repair scanning is a comprehensive diagnostic tool that plays a pivotal role in modern vehicle maintenance. It involves advanced technology to thoroughly inspect and identify potential issues within a Tesla vehicle, ranging from minor problems like auto dent repair to more complex tasks such as frame straightening or fender repair. This process captures detailed data, allowing technicians to pinpoint exact locations of damage, measure severity, and access vehicle-specific information.

By utilizing specialized equipment, the scanning system reads and deciphers codes from the car’s computer systems. These codes often signal subtle anomalies that may not be immediately apparent during a visual inspection. Each logged code corresponds to specific components or systems—brakes, engine, transmission, lighting—and can indicate everything from routine maintenance needs to more serious repairs. This data-driven approach ensures that any service is tailored to the exact requirements of the Tesla, enhancing efficiency and effectiveness in auto repair processes.

The Data Captured: What Information is Collected During Pre-Repair Scans

During a pre-repair Tesla scanning process, several critical data points are captured to provide an accurate assessment of the vehicle’s condition. This includes detailed information about the car’s frame, components, and structural integrity using advanced diagnostic tools. The scan logs various parameters such as sensor readings, computer modules’ status, and any fault codes stored in the vehicle’s system.

This process also involves capturing visual data through high-resolution cameras that document existing damage, paint defects, or previous repairs. In addition to structural and cosmetic insights, pre-repair scanning offers valuable information about a Tesla’s history, including service records, accident reports, and previous estimates from body shop services or collision repair shops. This comprehensive data collection ensures that any necessary car paint services are accurately tailored to the vehicle’s unique needs.

Flagged Issues: Identifying and Addressing Potential Problems Before Repair

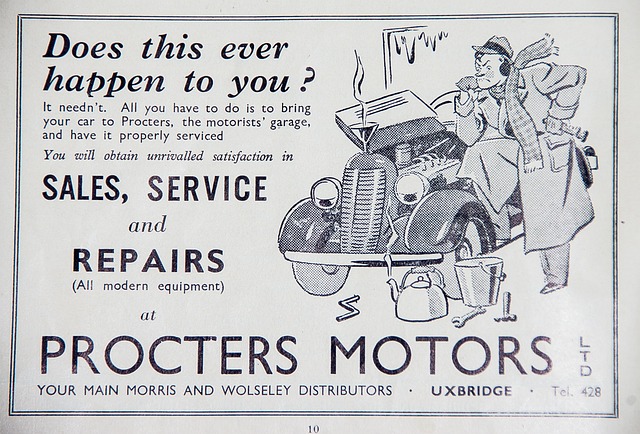

When a vehicle undergoes Tesla repair scanning, various data points are logged and analyzed to identify potential issues. This process is crucial in predicting and preventing more significant problems before they require extensive repairs or even necessitate a visit to a collision center or vehicle body shop. By flagging these issues early on, auto repair shops can provide proactive solutions, ensuring customer safety and satisfaction.

Flagged issues can range from minor concerns like sensor malfunctions to more critical problems such as structural damage. Advanced scanning tools enable technicians to detect even the subtlest anomalies, allowing them to address potential risks before they escalate. This not only saves time and money for both customers and auto repair shops but also contributes to maintaining the vehicle’s optimal performance and safety standards.

Tesla repair scanning is a powerful tool for ensuring vehicle health and safety. By meticulously logging and flagging critical data during pre-repair scans, workshops can proactively identify potential issues before beginning any work. This not only streamlines the repair process but also enhances customer satisfaction by preventing unexpected repairs or costs. Understanding what gets logged and flagged empowers owners to be more involved in their Tesla’s maintenance, fostering a culture of proactive vehicle care.