Seam sealer application is a critical step in auto collision repair, enhancing structural integrity and aesthetic appeal while preventing water intrusion and corrosion. Technicians at collision centers use specialized tools to apply sealers evenly, protecting vehicle interiors and exteriors. Visual inspection using natural or artificial light detects imperfections like bubbles, cracks, and uneven distributions, ensuring a seamless, durable finish. Maintaining rigorous standards, regular equipment maintenance, proper training, and thorough surface cleaning before application are key to preventing defects and guaranteeing high-quality seam sealer application in vehicle repair services and auto glass repair.

Ensure top-notch seam sealer application quality with these valuable visual inspection tips. This guide equips you with the essentials of understanding seam sealer basics and effective inspection techniques for guaranteed excellence. Learn to identify and prevent common defects, ensuring robust bonds and lasting performance in various industries. Master the art of visual assessment for optimal seam sealer application results.

- Understanding Seam Sealer Application Basics

- Visual Inspection Techniques for Quality Assurance

- Common Defect Identification and Prevention

Understanding Seam Sealer Application Basics

Seam sealer application is a critical step in any auto collision repair or car bodywork services process, ensuring the durability and longevity of vehicle repairs. It involves carefully applying a sealant along vehicle joints and seams to prevent water intrusion and corrosion. A quality seam sealer not only enhances the structural integrity of the car body but also contributes to its overall aesthetic appeal.

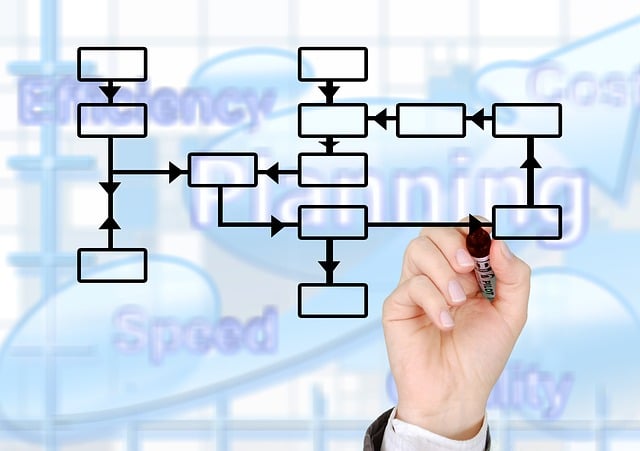

Understanding the proper application techniques is key. This includes preparing the surface, choosing the right sealer for the specific material, and applying it evenly using the appropriate tools. At an auto collision center, skilled technicians utilize specialized equipment like brushes, rollers, or spray guns to achieve a smooth, consistent coat. By paying meticulous attention to detail during this process, they ensure that every seam is sealed effectively, safeguarding the car’s interior and exterior from potential damage caused by moisture and elements.

Visual Inspection Techniques for Quality Assurance

Visual inspection is a critical step in ensuring the quality of seam sealer application during vehicle repairs, such as those seen in Mercedes-Benz models. Skilled technicians employ various techniques to detect even the slightest imperfections. One common method involves examining the surface under natural or artificial light, looking for any bubbles, cracks, or uneven distributions of the sealer. This meticulous process requires sharp observation skills and a keen eye for detail.

Additionally, cross-lighting techniques can highlight subtle variations in the sealer’s texture and consistency, enabling professionals to identify potential issues before they affect auto body painting. In the context of vehicle repair, maintaining high standards during visual inspection is vital to prevent future problems and ensure a seamless, durable finish across all surfaces.

Common Defect Identification and Prevention

During visual inspection, one of the primary tasks is to identify and prevent common defects in seam sealer application. Familiarize yourself with the telltale signs of poor workmanship, such as uneven or bubbly seals, gaps between panels, and misaligned edges. These issues can lead to leaks, compromising the integrity of vehicle repair services and auto glass repair. Regularly inspect tools and equipment for wear and tear, ensuring they are in optimal condition. Proper training and adherence to best practices significantly reduce these defects.

Additionally, pay close attention to preparation steps like surface cleaning and degreasing. Unclean surfaces can result in poor adhesion and eventual seal failure, impacting car repair services. By identifying and rectifying these problems early on, you enhance the quality of seam sealer application, ensuring lasting results for any vehicle undergoing repairs or maintenance.

When it comes to achieving top-quality seam sealer application, visual inspection is a vital step. By employing techniques discussed in this article, such as examining for even coats and identifying potential defects like runs or puddles, you can ensure optimal performance and longevity of your sealants. Regular visual checks during and after application are key to preventing issues, ultimately enhancing the overall quality of seam sealer application processes.