Plasma cutting collision repair has transformed the automotive industry by providing a precision, speed, and efficiency advantage over traditional manual methods. This advanced technology enables accurate, clean cuts through various materials, facilitating intricate repairs and restoring vehicles to pre-accident condition. Its benefits include quicker turnaround times, reduced waste, and improved accuracy, making it ideal for complex dent repairs and setting new industry standards in quality and customer satisfaction.

In the realm of automotive restoration, Plasma Cutting Collision Repair has emerged as a game-changer. This article delves into the transformative journey that began with the evolution of collision repair techniques and culminated in the adoption of plasma cutting technology. Initially, this innovative approach revolutionized metal fabrication, precision welding, and material waste reduction. Today, its revolutionary effects extend to enhanced vehicle safety, streamlined repair processes, and environmental sustainability—marking a significant shift in the auto industry’s landscape.

- The Evolution of Collision Repair Techniques

- – A historical perspective on collision repair methods

- – Introduction of plasma cutting technology and its initial impact

The Evolution of Collision Repair Techniques

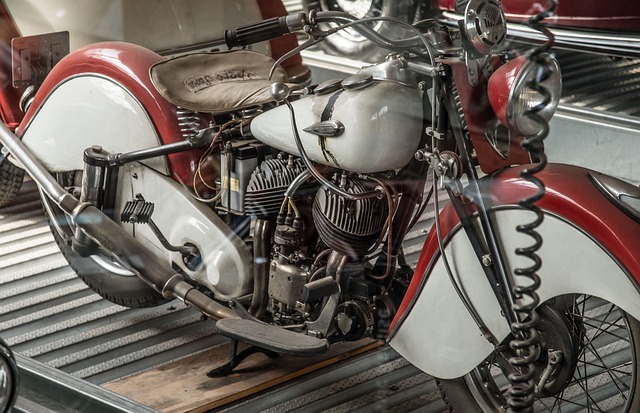

The evolution of collision repair techniques has been a transformative journey, with plasma cutting collision repair playing a pivotal role in shaping the modern auto industry. Traditional methods, once dominant, involved extensive manual labor and time-consuming processes. However, the introduction of advanced technologies like plasma cutting has revolutionized car repair services. This innovative technique offers precision, speed, and efficiency unparalleled by conventional methods, reducing the need for intensive human intervention.

Plasma cutting collision repair has not only enhanced the accuracy of repairs but also opened doors to new possibilities in paintless dent repair. With its ability to cut through various materials with exceptional control, plasma cutting enables technicians to perform intricate repairs without compromising the original finish. This advancement is particularly noteworthy in the context of collision repair services, where maintaining the car’s aesthetic value is a priority. As a result, vehicles can be restored to their pre-accident condition, showcasing the industry’s ongoing commitment to quality and customer satisfaction through cutting-edge solutions.

– A historical perspective on collision repair methods

Collision repair has a long history, evolving from simple, often crude methods to today’s advanced techniques. In the early days, repairs were primarily carried out through manual labor and basic tools, with metalwork performed by skilled artisans. Bending, hammering, and welding were the primary means of fixing damaged vehicles, a process that was both time-consuming and prone to human error. As the auto industry grew, so did the need for more efficient and standardized repair methods.

The introduction of plasma cutting technology in collision repair has been transformative. Plasma cutting collision repair allows for precise, fast, and clean cuts through various materials, including metal. This innovation has revolutionized auto body restoration, enabling technicians to achieve intricate designs and accurate fits with minimal effort. Furthermore, it has streamlined the fender repair process, making it more accessible and cost-effective while improving overall vehicle aesthetics and structural integrity.

– Introduction of plasma cutting technology and its initial impact

The introduction of plasma cutting technology revolutionized the auto industry, particularly in the realm of collision repair. This innovative process, which uses a high-velocity stream of ionized gas to cut through metal with precision and speed, offered a game-changer for auto repair services. Initially, plasma cutting collision repair promised quicker turnaround times, reduced material waste, and improved accuracy compared to traditional cutting methods like oxyacetylene welding. Its ability to handle complex shapes and tight spaces made it ideal for intricate car dent repairs, transforming the way vehicle collision repair was approached.

The impact of plasma cutting technology was swiftly felt across the industry. Auto body shops that adopted this method witnessed increased efficiency, enabling them to complete repairs faster and serve customers more promptly. Moreover, the precision afforded by plasma cutting reduced the risk of errors, ensuring cleaner cuts and ultimately leading to higher-quality auto repair services. As the benefits became evident, the adoption of plasma cutting technology spread, paving the way for a new era in collision repair and setting a new standard for excellence in vehicle collision repair.

Plasma cutting collision repair has fundamentally transformed the auto industry, offering faster, more precise, and cost-effective solutions compared to traditional methods. This advanced technology has not only enhanced the efficiency of repair processes but also improved the overall quality of vehicle restoration. As plasma cutting continues to evolve, its integration into collision repair will likely lead to even greater innovations in the future, further revolutionizing the way we approach automotive damage restoration.