Corrosion, accelerated by moisture and oxygen, weakens vehicle structures after repairs, posing safety risks. Collision repair shops must implement effective corrosion prevention strategies using specialized coatings, rust inhibitors, and sealing agents to preserve structural integrity. This not only extends vehicle lifespan but also reduces future repair costs, making it a vital modern maintenance practice. Meticulous surface preparation and high-quality preventatives safeguard metal surfaces, enhancing strength and visual appeal while saving money for both shops and car owners. Proactive corrosion prevention in areas like the underbody and wheel wells decreases component failure risk, fostering trust between owners and repair shops committed to collision body restoration excellence.

Corrosion is a vehicle’s silent enemy, especially after repair or collision. Understanding its impact on durability is key to ensuring long-lasting performance. This article delves into the critical role of corrosion prevention strategies post-collision in enhancing vehicle longevity. We explore how proactive control measures not only save costs but also safeguard against structural damage and aesthetic deterioration. By implementing effective corrosion prevention techniques, repair shops can deliver superior results, ensuring satisfied customers and a safer driving experience.

- Understanding Corrosion and its Impact on Vehicle Repairs

- Implementing Effective Corrosion Prevention Strategies Post-Collision

- Longevity and Cost Savings: The Benefits of Proactive Corrosion Control

Understanding Corrosion and its Impact on Vehicle Repairs

Corrosion is a natural process that can significantly impact vehicle durability, especially after repairs. When metal surfaces are exposed to moisture and oxygen, they undergo chemical reactions, leading to the degradation of their structure and strength. This phenomenon is particularly problematic in automotive repairs, as even minor corrosion can weaken crucial components, compromising safety and performance. In the context of collision repair, where vehicles may sustain significant damage, effective corrosion prevention becomes an essential step in ensuring long-lasting results.

In an auto repair shop, especially after frame straightening or vehicle collision repair, technicians must take proactive measures to prevent corrosion. This involves using specialized coatings, rust inhibitors, and sealing agents during the restoration process. By creating a protective barrier between metal surfaces and potential corrosive elements, these measures significantly enhance the longevity of repairs. Preventing corrosion not only maintains the structural integrity of vehicles but also saves time and costs associated with future repairs, making it a crucial aspect of modern vehicle maintenance practices.

Implementing Effective Corrosion Prevention Strategies Post-Collision

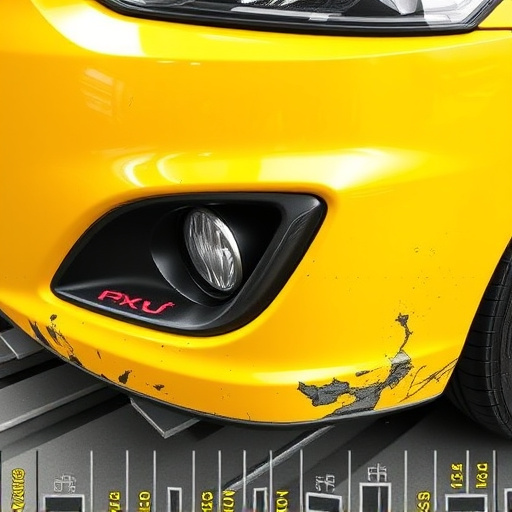

After a collision, effective corrosion prevention strategies are essential to ensure long-term durability for vehicles undergoing repairs, particularly in an auto body shop. The initial step involves meticulous surface preparation, which includes cleaning, degreasing, and sanding to remove any debris or contaminants that might hinder paint adhesion. This meticulous process creates a smooth base, allowing for better bonding of corrosion-inhibiting coatings.

Additionally, applying high-quality rust preventatives and undercoating before painting is pivotal in shielding metal surfaces from future moisture intrusion. These protective layers form a barrier, preventing corrosion and ensuring the integrity of the repaired parts, especially during fender repair or collision repair processes. Such strategies not only enhance the structural strength of vehicles but also contribute to their visual appeal and overall longevity.

Longevity and Cost Savings: The Benefits of Proactive Corrosion Control

Corrosion prevention plays a pivotal role in extending the lifespan of vehicles post-repair, offering significant advantages in terms of longevity and cost savings for both auto repair shops and car owners. By implementing proactive corrosion control measures, auto detailing professionals can significantly enhance the durability of vehicle components, particularly in areas prone to rust and decay, such as the underbody and wheel wells.

This strategy not only safeguards against premature failure but also reduces the financial burden associated with repeated repairs. In the long run, a well-maintained vehicle is more valuable, ensuring peace of mind for owners and fostering trust in auto repair shops that prioritize corrosion prevention during car body restoration processes.

By implementing robust corrosion prevention strategies after vehicle collisions, repair shops can significantly enhance durability and longevity. These proactive measures not only protect against future damage but also offer cost savings for both owners and repair facilities. Effective corrosion control is a key component in ensuring vehicles stand the test of time, maintaining their structural integrity and aesthetic appeal.