UV paint curing systems revolutionize collision repair by offering unprecedented speed and quality. Utilizing ultraviolet light for polymerization, these systems cure paint up to 10 times faster than traditional methods, reducing turnaround times and increasing shop capacity. They ensure even, high-quality finishes, minimizing rework. LED technology makes UV systems energy-efficient and eco-friendly. Best practices, including proper surface prep, lighting use, curing times, temperature/humidity control, maintenance, and ventilation, enhance system performance for optimal vehicle restoration outcomes.

In today’s competitive auto repair landscape, adopting innovative technologies can set shops apart. One such game-changer is the UV (ultraviolet) paint curing system. This article delves into the workings of UV paint curing systems and explores their myriad benefits for auto shops. We’ll discuss how these systems revolutionize painting processes, enhance efficiency, and contribute to higher-quality finishes. Additionally, we’ll provide best practices and considerations for implementing this technology effectively.

- Understanding UV Paint Curing Systems: How They Work

- Benefits of Implementing UV Technology in Auto Shops

- Best Practices and Considerations for Effective UV Paint Curing

Understanding UV Paint Curing Systems: How They Work

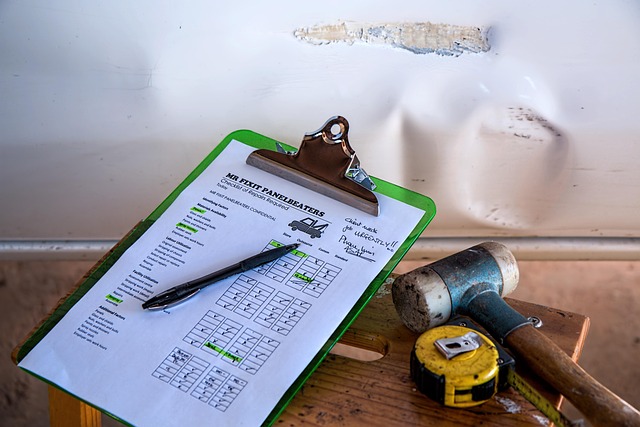

UV paint curing systems have revolutionized collision repair services and auto body painting processes in collision repair shops. Unlike traditional drying methods, these innovative systems utilize ultraviolet (UV) light to initiate a chemical reaction within the paint, hardening it rapidly. This technology ensures that vehicles undergo a faster turnaround time without compromising quality.

When a UV paint curing system is employed during auto body painting, the UV light energy triggers a photoinitiator in the paint, which starts a polymerization process. This transformation solidifies the paint layer, making it durable and resistant to chips, scratches, and other forms of damage. The efficiency and precision of UV systems are particularly beneficial for collision repair shops, allowing them to restore vehicles to their pre-incident condition swiftly and effectively.

Benefits of Implementing UV Technology in Auto Shops

Implementing UV paint curing systems in auto shops offers a multitude of benefits that significantly enhance efficiency and quality in automotive collision repair and auto body restoration processes. One of the key advantages is speed; UV technology curings paint up to 10 times faster than traditional methods, reducing downtime for both customers and shop operations. This swift process translates into quicker turnaround times, allowing shops to accommodate more vehicles and meet customer demands effectively.

Moreover, UV paint curing systems are highly precise, ensuring consistent and even paint application across auto body work surfaces. This precision leads to superior finish quality, minimizing the need for touch-ups or rework, which can save time and resources. Additionally, UV technology uses energy-efficient LED lights, making it an environmentally friendly option by reducing electricity consumption compared to conventional curing methods.

Best Practices and Considerations for Effective UV Paint Curing

For auto shops implementing UV paint curing systems, best practices ensure optimal results and efficiency in vehicle restoration and bodywork projects. Firstly, ensure proper surface preparation is paramount before applying the UV coating. This includes cleaning, priming, and sanding to achieve a smooth base for the cure. The right lighting system, typically LED or UV lamps, should be used according to the manufacturer’s specifications for the chosen paint type. Curing times vary based on factors like lamp intensity, paint composition, and vehicle size, so adhering to recommended durations is crucial.

Additionally, maintaining a controlled environment is vital. This involves managing temperature and humidity levels within acceptable ranges, as these conditions significantly impact curing speed and quality. Proper ventilation is also essential in auto collision centers to prevent the buildup of volatile organic compounds (VOCs). Regular maintenance and calibration of UV paint curing systems are necessary to ensure consistent performance over time, contributing to the overall success of vehicle restoration projects.

UV paint curing systems offer auto shops a modern, efficient solution for fast and durable finishes. By understanding their functionality and implementing best practices, shops can leverage UV technology’s benefits, including reduced dry times, improved quality, and enhanced productivity. This innovative approach to painting ensures autos are restored with precision and speed, meeting modern consumer demands.