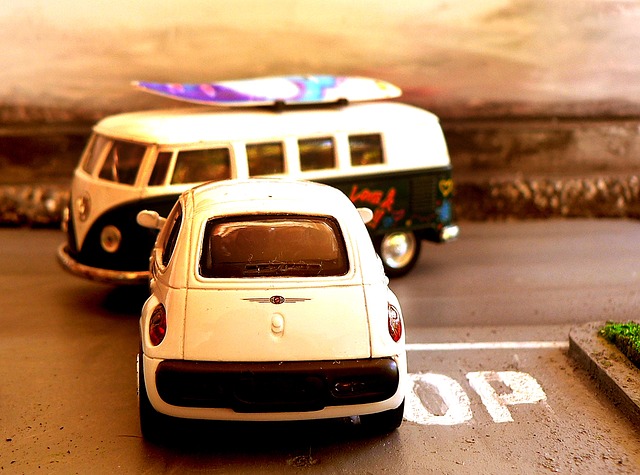

Paintless Damage Repair (PDR) is an advanced auto body technique using specialized tools to non-invasively remove dents and dings, preserving the original factory finish and reducing repair times. Effective PDR equipment features durable construction, precise design, and innovative technology for tailored repairs. Choosing the right PDR equipment is crucial for efficient hail damage restoration, with versatile sets for minor dents and specialized tools for heavier damage. Auto repair shops should invest in high-quality PDR equipment from reputable manufacturers to ensure consistent, accurate results.

“Discover the ultimate tools for efficient hail damage repair with our guide to the best PDR (Paintless Damage Repair) equipment. Paintless dent repair is a popular and cost-effective method to restore vehicles without traditional painting, saving time and money. This article explores the essential components of top-tier PDR kits, helping you choose the right tools for the job. From impact guns to pullers, we’ll uncover the must-haves for achieving flawless repairs. Boost your restoration skills with the right PDR equipment.”

- Understanding PDR (Paintless Damage Repair) and Its Benefits

- Key Components of Top-Notch PDR Equipment

- Choosing the Right PDR Tools for Hail Damage Restoration

Understanding PDR (Paintless Damage Repair) and Its Benefits

Paintless Damage Repair (PDR) is a specialized auto body repair technique that has revolutionized the way dents and dings are fixed. Unlike traditional methods that often involve sandblasting, painting, and significant panel replacement, PDR uses advanced tools and equipment to remove dents non-invasively, preserving the original factory finish. This process is particularly beneficial for minor cosmetic damages, such as hail damage, door dings, and edge cracks, making it a preferred choice for many auto collision centers and body shop services.

By utilizing PDR equipment, technicians can perform dent removal efficiently without affecting the integrity of the vehicle’s metal or requiring extensive preparation. This not only reduces repair times but also lowers costs for both customers and auto shops. Moreover, PDR equipment allows for precise work, ensuring minimal to no paint scraping, which is a significant advantage over traditional methods. As a result, vehicles can look as good as new, maintaining their resale value and aesthetic appeal.

Key Components of Top-Notch PDR Equipment

The effectiveness of Professional Detaching Repair (PDR) work heavily relies on the quality and functionality of the equipment used. Top-notch PDR tools are designed to efficiently address various auto bodywork issues, from minor dents and dings to more complex auto body painting needs. Key components that define superior PDR equipment include durable construction, precise design, and innovative technology. High-quality tools often boast ergonomic handles for comfort during extended use, ensuring technicians can work with precision and speed.

Additionally, modern PDR equipment incorporates advanced features like adjustable settings, versatile attachment options, and digital displays for improved control and accuracy. These innovations allow professionals to tailor their approach based on the specific damage, whether it’s a simple paintless dent repair or more intricate auto body painting tasks. Such equipment not only streamlines the repair process but also enhances the overall quality of the final restoration, ensuring vehicles return to their pre-incident condition.

Choosing the Right PDR Tools for Hail Damage Restoration

Choosing the right PDR (Paintless Damage Repair) tools is paramount for efficient and effective hail damage restoration work. When evaluating PDR equipment, consider the extent and complexity of the damage. For minor dings and dents, a versatile set including a hammer, tap, and various pullers might suffice. However, heavier or more extensive hail damage may require specialized tools like rotary tools, metal detectors, and even automatic or robotic systems.

An auto repair shop or collision repair facility engaged in auto bodywork restoration should invest in high-quality PDR equipment to ensure consistent results and minimize downtime for customers’ vehicles. Opting for durable, user-friendly tools from reputable manufacturers can significantly enhance the efficiency of the work and reduce the risk of further damaging the vehicle’s finish during the repair process.

When it comes to hail damage repair, investing in high-quality PDR (Paintless Damage Repair) equipment is key to efficient and effective restoration. By understanding the benefits of PDR and selecting the right tools, professionals can deliver exceptional results while saving time and resources. Top-notch PDR equipment, featuring innovative designs and durable construction, ensures precision and ease during the repair process, making it an indispensable asset for any hail damage restoration specialist.