PDR (Paintless Dent Repair) for steel panels is revolutionizing auto repair by offering a non-invasive, efficient, cost-effective, and environmentally friendly method to address dents and scratches. This technique preserves the original factory finish, reduces repair time, and maintains structural integrity, enhancing vehicles' resale value in today's digital age where buyers prioritize visual appeal. Implementing PDR requires strategic steps including workspace preparation, tool selection, technician training, and setting quality standards, integrating it into existing workflows to maximize efficiency and resale value.

In today’s competitive market, maximizing resale value is paramount. Professional Damage Repair (PDR) stands out as a game-changer for steel panel aesthetics and worth. This article explores how PDR can revitalize damaged steel panels, enhancing their appeal and ultimately boosting resale potential. From understanding the PDR process to uncovering its benefits and implementation strategies, we’ll delve into practical ways to optimize results and preserve the value of your steel assets.

- Understanding PDR and Its Impact on Steel Panels

- The Benefits of PDR for Resale Value Enhancement

- Implementation Strategies for Optimal Results

Understanding PDR and Its Impact on Steel Panels

PDR, or Paintless Dent Repair, is a cutting-edge technique revolutionizing the way we address dents and scratches on steel panels, primarily in the automotive industry. Unlike traditional collision repair methods that involve extensive painting and restructuring, PDR is a non-invasive process that restores damaged surfaces to their original condition without the need for repainting. This method has gained immense popularity among both vehicle owners and collision repair shops due to its efficiency and cost-effectiveness.

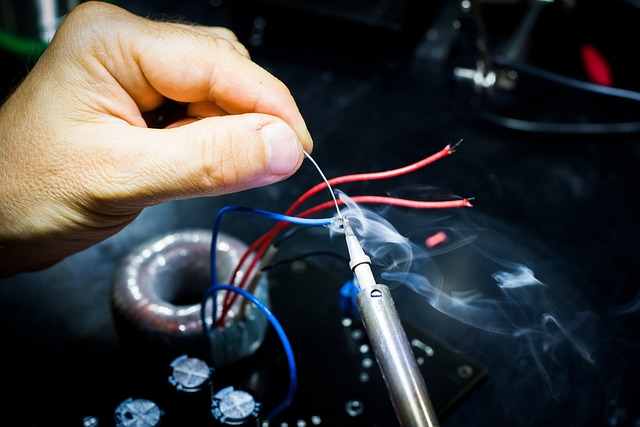

By utilizing specialized tools and techniques, PDR allows for precise manipulation of dented or scratched areas, gently pushing out the dents from the underlying metal. This not only conserves the original factory finish but also significantly reduces repair time compared to conventional vehicle body repair. As a result, car restoration efforts become more accessible, affordable, and environmentally friendly, ensuring that steel panels maintain their structural integrity and aesthetic appeal over time.

The Benefits of PDR for Resale Value Enhancement

PDR for steel panels is a game-changer when it comes to enhancing resale value. This non-invasive technique, often used in vehicle body repair, has proven its worth in the automotive industry and beyond. By restoring damaged or dented steel panels to their original condition, PDR not only improves the aesthetic appeal but also significantly increases the overall marketability of a vehicle. In today’s digital era, potential buyers are increasingly looking for well-maintained and visually appealing cars, making PDR an essential tool for auto repair services aiming to maximize resale value.

Compared to traditional painting or replacement methods, PDR offers several advantages. It preserves the original factory finish, which is often more valuable than a repaint job. Moreover, it’s a cost-effective solution that can save both time and money while ensuring long-lasting results. This versatility makes PDR an attractive option for vehicle paint repair, allowing for quick turnaround times without compromising quality. As a result, steel panels treated with PDR methods retain their value better, providing a significant competitive edge in the resale market.

Implementation Strategies for Optimal Results

Implementing PDR for steel panels requires a strategic approach to achieve optimal results. It’s not just about the technique itself but also preparing your workspace and tools, ensuring proper training for technicians, and establishing clear quality standards. Starting with an assessment of the panel’s damage and choosing the right equipment tailored to steel is crucial. Proper preparation, including surface cleaning and decontaminating, lays the foundation for successful repairs.

For best practices, consider integrating PDR into your existing auto repair services or car paint services workflow. Standardizing processes and setting benchmarks for finish quality will help maintain consistency. Regular training sessions and updates on industry best practices for both employees and technicians involved in steel panel repairs are essential. This ensures that everyone is up-to-date with the latest techniques, enhancing overall efficiency and resale value.

PDR (Paintless Dent Repair) is a game-changer in enhancing the resale value of steel panels. By effectively removing dents and scratches without painting, PDR not only restores the aesthetic appeal of these panels but also increases their marketability. The benefits are clear: it’s a cost-effective solution that saves time and resources while ensuring a higher resale price for vehicle owners and a competitive edge for dealers. Implementing PDR as part of regular maintenance routines can significantly contribute to optimal panel condition, ultimately enriching the overall automotive industry landscape.