Auto body fasteners (bolts, nuts, screws, rivets, clips) are essential for vehicle structural integrity & aesthetics, with each type serving unique purposes. Before any repair or painting, a thorough visual inspection is critical to check for corrosion, rust, damage, and ensure all components are present & securely fastened. Testing methods like ultrasonic & magnetic particle inspections ensure fastener safety & quality in auto frame repair & restoration.

Before installing auto body fasteners, proper inspection is crucial for ensuring safety and quality. This guide delves into the essential practices for evaluating these critical components, helping you navigate the process efficiently. We’ll explore different types of auto body fasteners and their significance in vehicle construction. Then, we’ll detail what to look for during visual inspections and discuss effective testing methods. By mastering these steps, you’ll be equipped to ensure your auto body repairs are both durable and secure.

- Understanding Auto Body Fasteners: Types and Importance

- Visual Inspection: What to Look For Before Installation

- Effective Testing Methods for Ensuring Quality and Safety

Understanding Auto Body Fasteners: Types and Importance

Auto body fasteners are essential components in maintaining the structural integrity and overall aesthetics of a vehicle. These include a wide range of fastening devices such as bolts, nuts, screws, rivets, and clips, each designed for specific purposes. Understanding their types is crucial for anyone involved in auto dent repair or working at a car body shop. For instance, automotive bolts, often made of high-strength steel, are used to secure major components like the engine block or transmission while rivets, on the other hand, are commonly utilized in areas that require increased flexibility and resistance to shock.

Properly examining auto body fasteners before installation is vital for ensuring the safety and durability of the car bodywork. This involves checking for signs of corrosion, damage, or misalignment that could compromise their strength and effectiveness. A thorough inspection can help prevent costly repairs down the line by identifying issues early on, making it an indispensable step in both auto dent repair processes and routine car body shop maintenance routines.

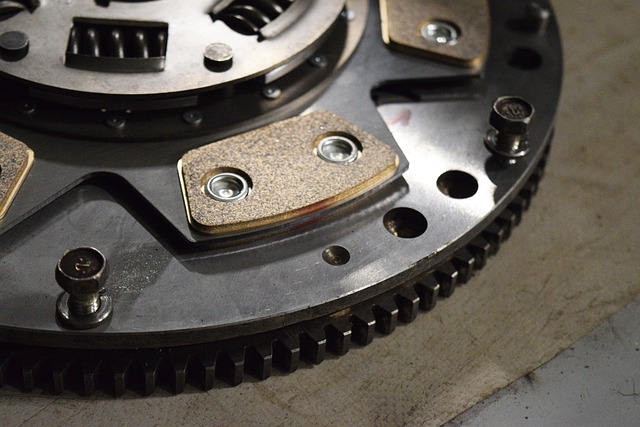

Visual Inspection: What to Look For Before Installation

Before tackling any auto body repair job, a thorough visual inspection of the fastener condition is paramount. Auto body fasteners, such as nuts, bolts, and screws, play a crucial role in ensuring structural integrity during vehicle collision repair or car bodywork projects. During your initial assessment, look for signs of corrosion, rust, or damage that might compromise their strength and longevity.

Focus on areas prone to wear and tear, including the edges, threads, and heads of the fasteners. Corrosion often appears as a discolored patch or pitting on metal surfaces. In the case of auto painting, it’s essential to inspect fasteners hidden beneath the surface to prevent paint issues later. Ensure all components are present, intact, and securely fastened before proceeding with any repair or painting work on your car bodywork.

Effective Testing Methods for Ensuring Quality and Safety

Ensuring the quality and safety of auto body fasteners is paramount before installation, especially for critical components in auto frame repair and vehicle restoration. Several effective testing methods have emerged to meet these demands. One such method involves using advanced non-destructive testing (NDT) techniques like ultrasonic testing, which detects internal flaws or inconsistencies without damaging the fasteners. This method is particularly crucial in collision repair shops where precision and reliability are key.

Another powerful tool is magnetic particle inspection (MPI), which utilizes a magnetic field to uncover surface defects in metallic components. MPI is highly effective for checking auto body fasteners, especially those made of ferromagnetic materials. Additionally, visual inspection remains a fundamental step, requiring trained technicians to meticulously examine fasteners for any signs of damage, corrosion, or misalignment, further bolstering the safety and integrity of the installation process in both collision repair shops and vehicle restoration projects.

Before installing any auto body fasteners, a thorough inspection is vital. This process ensures that only high-quality, secure fastening solutions are used, enhancing vehicle safety and longevity. By understanding different types of auto body fasteners and employing effective testing methods, you can navigate the market with confidence, choosing the best options for each specific repair or upgrade. Regular visual inspections and adherence to quality standards will ultimately contribute to better craftsmanship and more reliable vehicle performance.