Plasma cutting collision repair revolutionizes auto bodywork with its precision, efficiency, and versatility. This technology allows technicians to navigate complex bodywork effortlessly, making clean, accurate cuts that minimize waste and maximize recycling opportunities. From steel to aluminum, plasma cutting offers a non-invasive approach that preserves vehicles' structural integrity, resulting in superior repairs that enhance longevity and performance. It's particularly effective in Mercedes Benz repair, speeding up the process while ensuring meticulous quality. By reducing labor costs and minimizing waste compared to traditional methods, plasma cutting collision repair offers cost and time savings without compromising on quality.

Plasma cutting collision repair has emerged as a game-changer for automotive technicians, offering unprecedented precision and efficiency. This advanced technology leverages plasma arcs to cut through various materials, making it indispensable in today’s demanding collision repair landscape. By adopting plasma cutting, technicians can achieve faster turnaround times, reduce material waste, and deliver superior, more accurate repairs. In this article, we explore the advantages, cost-effectiveness, and time-saving benefits of plasma cutting collision repair, highlighting why it’s a must-have skill for modern auto body professionals.

- The Advantages of Plasma Cutting Technology for Collision Repair

- Efficient and Precise: How Plasma Cutting Enhances Collision Repair Accuracy

- Cost-Effectiveness and Time-Saving Benefits of Plasma Cutting Collision Repair

The Advantages of Plasma Cutting Technology for Collision Repair

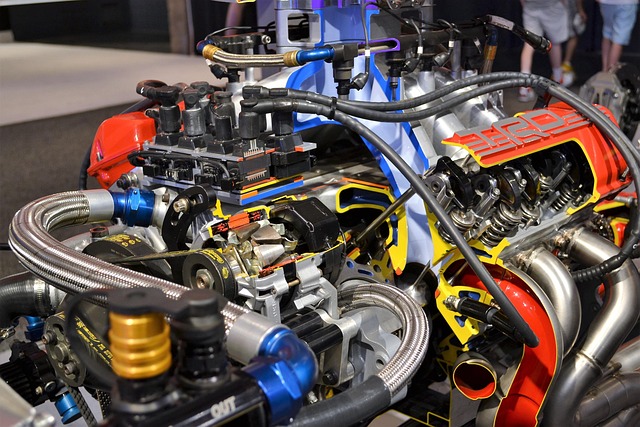

Plasma cutting technology has revolutionized the landscape of collision repair, offering numerous advantages over traditional methods. Its precision and efficiency are unparalleled, allowing technicians to navigate intricate vehicle bodywork with ease. This advanced technique ensures clean, accurate cuts, minimizing material waste and maximizing recycling opportunities in auto collision centers.

The versatility of plasma cutting enables repair professionals to handle a wide range of materials, from steel to aluminum, making it an indispensable tool in modern automotive collision repair. Moreover, its non-invasive nature preserves the structural integrity of vehicles, resulting in superior quality repairs that enhance vehicle longevity and performance.

Efficient and Precise: How Plasma Cutting Enhances Collision Repair Accuracy

Plasma cutting collision repair has revolutionized the automotive industry, offering technicians an efficient and precise method for auto frame repair. This advanced technology enables meticulous cuts with unparalleled accuracy, ensuring that every component is handled with care during the collision repair services process. Unlike traditional cutting methods, plasma cutting minimizes the risk of damage to surrounding areas, allowing for more detailed work and faster turnaround times.

For instance, in Mercedes Benz repair scenarios, where precision is paramount, plasma cutting ensures that parts are removed and replaced with meticulous accuracy. This level of detail not only speeds up collision repair services but also enhances the overall quality of the final product, resulting in a smoother and more seamless restoration for the vehicle.

Cost-Effectiveness and Time-Saving Benefits of Plasma Cutting Collision Repair

Plasma cutting collision repair offers significant cost-effectiveness and time-saving benefits for technicians engaged in auto body work. Traditional methods like torch cutting can be slower and more expensive, requiring specialized skills and consumables. In contrast, plasma cutting is a highly efficient process that utilizes an ionized gas to cut through various materials swiftly and accurately. This not only reduces labor costs but also minimizes material waste, making it an economical choice for both auto collision centers and car body repair shops.

By adopting plasma cutting techniques, technicians can achieve faster turnaround times without compromising on the quality of auto collision center services. The precision afforded by this method ensures clean cuts, which is crucial for seamless car body repair. This efficiency not only benefits the repair shop but also ultimately saves clients money by expediting their vehicle’s return to them.

Plasma cutting collision repair has revolutionized the automotive industry, offering a multitude of advantages over traditional methods. Its efficiency, precision, and cost-effectiveness make it an indispensable tool for technicians, ensuring faster turnaround times and superior quality repairs. By embracing this advanced technology, collision repair shops can elevate their services, save resources, and ultimately provide clients with outstanding results.