Computerized diagnostics repair (CDR) is revolutionizing auto maintenance by leveraging advanced technology for precise, efficient identifications of vehicle issues. This method enables mechanics to access real-time data from onboard computers, significantly reducing diagnosis times for engines, transmissions, electrical systems, and airbag mechanisms. CDR boosts efficiency, streamlines processes, enhances precision, and ultimately contributes to safer, more reliable vehicles, fostering customer satisfaction. Future trends include AI/machine learning predictions of potential failures and remote diagnostics, making CDR a transformative force in the automotive industry.

In today’s modern automotive landscape, computerized diagnostics repair (CDR) has emerged as a game-changer in auto maintenance. Understanding this technology, which enables vehicles to communicate their internal health through complex data networks, is crucial for both technicians and car owners. By leveraging CDR, mechanics can more efficiently diagnose issues, reducing time and costs while enhancing repair accuracy. This article explores the benefits of CDR, its underlying technology, and trends shaping its future in the automotive industry.

- Understanding Computerized Diagnostics Repair: Unlocking the Technology

- Benefits of Using Computerized Diagnostics in Auto Maintenance

- The Future of Automotive Repairs: Trends and Innovations in CDR

Understanding Computerized Diagnostics Repair: Unlocking the Technology

Computerized diagnostics repair has revolutionized auto maintenance by providing a sophisticated and accurate approach to identifying vehicle issues. This cutting-edge technology goes beyond traditional manual inspections, offering a deeper understanding of an automobile’s intricate systems. Modern vehicles are increasingly equipped with advanced computer networks that monitor and control various components, making them more complex than ever.

With computerized diagnostics repair, mechanics can access real-time data from these onboard computers, allowing for precise troubleshooting. This technology enables technicians to quickly diagnose problems in the engine, transmission, electrical systems, and even airbag mechanisms—a far cry from the laborious process of tracing issues through manual checks. By unlocking the potential of this innovative method, auto maintenance services can significantly improve efficiency, reduce repair times, and offer customers more accurate and reliable solutions, enhancing overall vehicle health.

Benefits of Using Computerized Diagnostics in Auto Maintenance

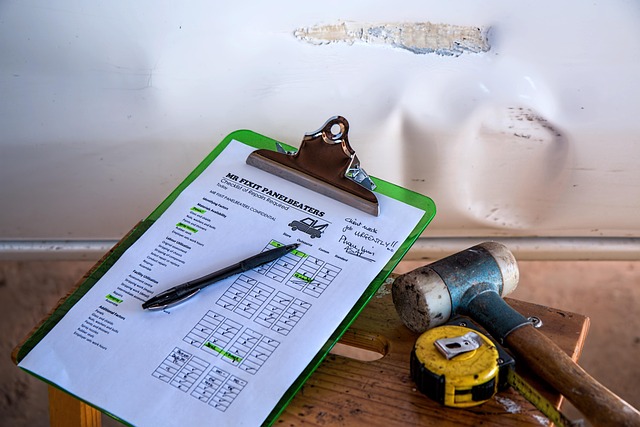

The integration of computerized diagnostics into auto maintenance routines has revolutionized the way vehicle repairs are approached. This technology plays a pivotal role in enhancing efficiency and precision during the servicing process. By employing advanced computer systems, mechanics can swiftly identify issues within a vehicle’s complex network of components, which is particularly beneficial for modern cars with intricate electronic systems. Computerized diagnostics repair allows for faster troubleshooting, reducing the time spent on manual inspections and increasing productivity at collision repair centers and shops.

Moreover, this digital approach ensures accuracy in diagnosing problems, which is crucial for effective auto body work. It provides a detailed analysis of sensor data, engine performance metrics, and other vehicle parameters, eliminating subjective guesses. This precision is especially valuable when dealing with subtle issues that might go unnoticed during conventional checks. As a result, computerized diagnostics repair not only streamlines maintenance processes but also contributes to safer and more reliable vehicles, fostering customer satisfaction at collision repair shops.

The Future of Automotive Repairs: Trends and Innovations in CDR

The future of automotive repairs is here, and it’s driven by technological advancements in Computerized Diagnostics Repair (CDR). As vehicles become increasingly complex with sophisticated electronic systems, CDR plays a pivotal role in ensuring efficient and precise maintenance. This cutting-edge technology allows mechanics to access real-time data from vehicle sensors, providing an accurate diagnosis of issues that may not be immediately apparent. With the ability to detect subtle anomalies, CDR revolutionizes the way auto repairs are conducted, making it faster and more cost-effective.

Trends in CDR include the integration of artificial intelligence and machine learning algorithms, enabling systems to predict potential failures and suggest proactive maintenance. This shift towards predictive analytics is a game-changer, especially for collision repair and paintless dent repair processes. By identifying issues early, mechanics can perform targeted repairs, reducing overall costs and minimizing downtime for vehicle owners. Additionally, the rise of remote diagnostics allows specialists to offer their expertise from distant locations, providing access to advanced auto maintenance services even in remote areas.

Computerized diagnostics repair (CDR) is transforming auto maintenance, offering numerous benefits such as faster and more accurate diagnoses. As technology advances, CDR will continue to evolve, with trends like enhanced scanning capabilities and improved data analysis. Embracing these innovations ensures mechanics keep pace with modern vehicles’ complex systems, ultimately leading to better vehicle performance and customer satisfaction.