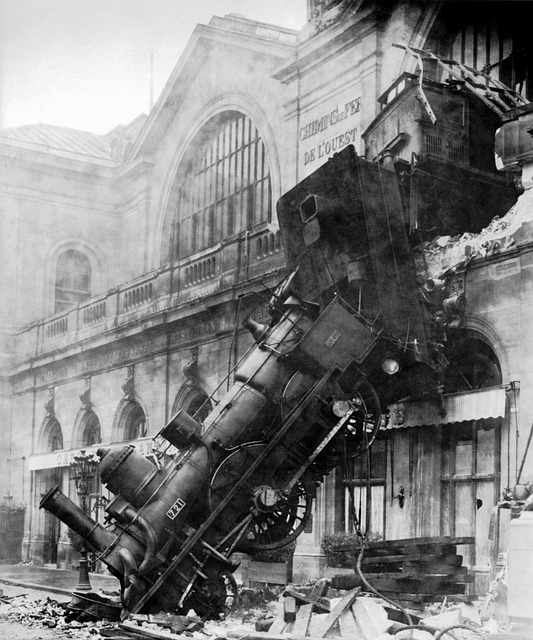

The tear down process, a critical step in vehicle servicing, involves meticulously dissecting cars to assess damage, identify worn-out components, and plan repairs. This method ensures accurate estimates, precise repair timelines, and minimizes hidden damage, leading to better customer satisfaction. Efficient tear down for estimate is a key strategy for optimizing time frames and enhancing workshop operations, allowing body shops to handle higher volumes while refining future repair processes. Technological advancements like 3D scanning further revolutionize this phase, simplifying estimates and communication with insurance providers or clients throughout the repair journey, including auto painting procedures.

In the realm of maintenance and repair, accurate estimation and optimized time frames are key to successful projects. The process of ‘tear down’ plays a pivotal role in determining these outcomes. This article explores the intricate steps involved in understanding and streamlining the tear-down process for precise estimation. By delving into efficient techniques, we uncover strategies to optimize repair time frames, ensuring timely completion without compromising quality. Discover tools and methods that revolutionize how you approach tear-downs, making every project a well-oiled machine.

- Understanding the Tear Down Process for Accurate Estimation

- Optimizing Repair Time Frames Through Efficient Tear Down

- Tools and Techniques to Streamline the Tear Down for Time Efficiency

Understanding the Tear Down Process for Accurate Estimation

The tear down process is a critical step in estimating repair costs and optimizing time frames for vehicle servicing. It involves meticulously dissecting the car to assess its condition, identify damaged or worn-out components, and determine the extent of necessary repairs. This methodical breakdown provides a clear picture of the work involved, allowing experts to offer precise estimates. By understanding the intricacies of each part’s role in the vehicle’s functionality, technicians can accurately forecast repair timelines for both minor services like auto painting and tire services, as well as more complex vehicle repair procedures.

This process is not merely about disassembly but also involves a thorough inspection of every component, from the chassis to the engine and interior finishes. This meticulous examination ensures that no hidden damage goes unnoticed, leading to more accurate budgeting for both labor and materials. Accurate estimation relies on this detailed understanding, which translates to better customer satisfaction and more efficient workshop operations by minimizing unexpected delays caused by unforeseen issues during auto painting or tire services.

Optimizing Repair Time Frames Through Efficient Tear Down

Efficient tear down for estimate plays a crucial role in optimizing repair time frames. By systematically disassembling a vehicle to access damaged components, technicians can accurately assess the scope of work required for vehicle collision repair or tire services. This meticulous process not only ensures that no hidden damage goes undetected but also allows for more precise planning and resource allocation.

With streamlined tear down procedures in place, body shop services can significantly reduce the time spent on preparation and diagnostics. This efficiency translates to quicker turnaround times, enhancing customer satisfaction and allowing workshops to handle a higher volume of repairs without compromising quality. Moreover, optimized tear down protocols can help identify common issues within specific vehicle models, further refining repair processes for consistent outcomes in future jobs.

Tools and Techniques to Streamline the Tear Down for Time Efficiency

In today’s competitive automotive industry, efficient tear-down processes are essential for optimizing repair time frames and reducing costs. Professional technicians rely on a combination of specialized tools and proven techniques to streamline this critical phase. For instance, high-quality extraction tools designed specifically for auto body restoration can significantly speed up the removal of damaged panels, making way for accurate measurements and estimates. These tools often feature advanced mechanisms that minimize the time spent on laborious tasks such as prying or hammering.

Furthermore, leveraging technology like 3D scanning and digital measuring systems has revolutionized tear-down procedures. These innovative solutions enable precise capture of vehicle dimensions, even in hard-to-reach areas, thereby simplifying the estimate process for both auto body restoration and dent removal. Additionally, digital documentation ensures a comprehensive record of the original condition, facilitating efficient communication with insurance providers or clients throughout the repair journey, including subsequent auto painting procedures.

By streamlining the tear-down process, estimating repair times with accuracy becomes achievable. This article has highlighted the importance of understanding the tear-down stages for precise estimations and how efficient navigation through this process can optimize repair timelines. Adopting the right tools and techniques ensures a swift and effective tear-down, leading to improved project management and client satisfaction. When planning repairs, consider the value of a meticulous tear-down as a foundation for successful optimization.