Full panel replacement is a critical, multi-step process in auto repair, addressing extensive exterior damage and structural issues. Skilled technicians inspect old panels, take precise measurements, and install new, specific model panels while adhering to strict quality control protocols. Quality outcomes require best practices like meticulous planning, high-quality materials, and adherence to manufacturer specs, as well as overcoming challenges like damaged underlying components and paint consistency using innovative technologies.

In the automotive industry, full panel replacement is a critical process ensuring vehicle aesthetics and safety. This article delves into the intricacies of quality control measures employed by shops specializing in this procedure. We’ll guide you through the step-by-step process, from initial assessment to final inspection, highlighting best practices and common challenges. By understanding these key aspects, you’ll gain insights into achieving top-notch panel replacement quality, ensuring both visual perfection and structural integrity.

- Understanding Full Panel Replacement: The Process and Its Significance

- Quality Control Measures: A Step-by-Step Guide for Shops

- Best Practices and Common Challenges in Achieving Top-Notch Panel Replacement Quality

Understanding Full Panel Replacement: The Process and Its Significance

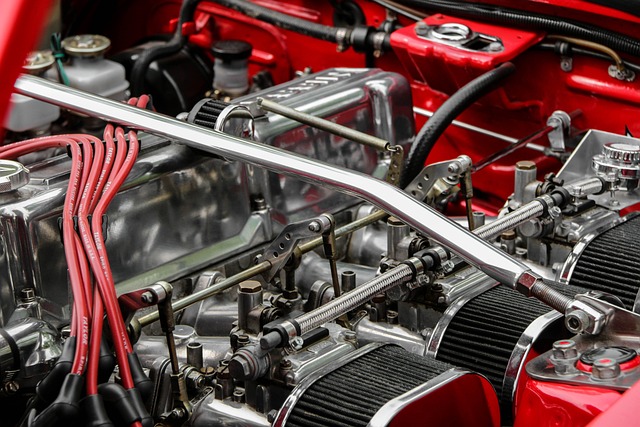

Full panel replacement is a critical process within the realm of auto frame repair and collision repair. It involves the complete exchange of an automobile’s exterior panels that have been damaged, typically due to accidents or other impacts. This method is significant as it restores the vehicle’s structural integrity and aesthetic appeal, ensuring it meets safety standards.

During this procedure, skilled technicians carefully remove the affected panels, replacing them with new ones that match the vehicle’s make and model precisely. Unlike partial repairs, full panel replacement aims to return the car to its original state, addressing not just visible damage but also potential underlying structural issues. This comprehensive approach is essential for maintaining the overall quality and longevity of the automobile in the long run, offering owners peace of mind on the road.

Quality Control Measures: A Step-by-Step Guide for Shops

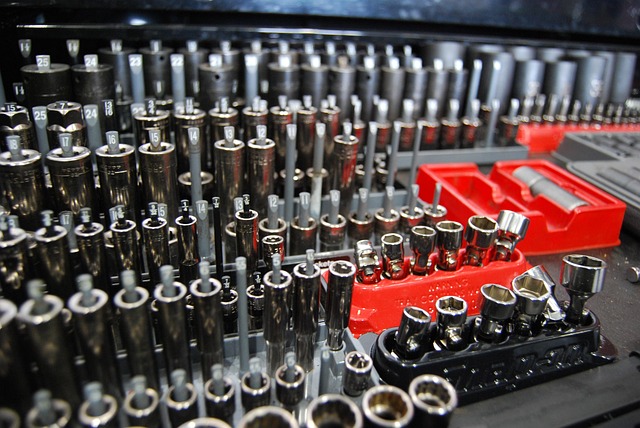

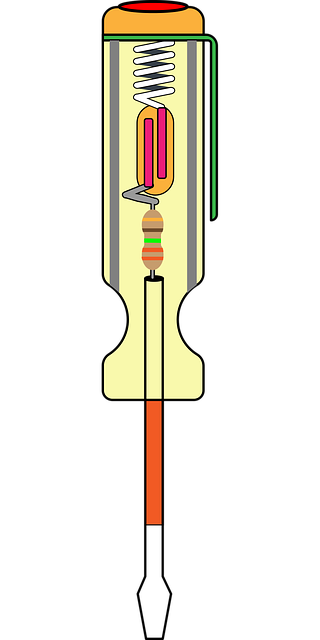

Ensuring quality control during full panel replacement is paramount for shops to maintain customer satisfaction and vehicle integrity. The process begins with a meticulous inspection of the old panel, identifying any defects or damage that could impact the new replacement. This includes checking for cracks, dents, rust, and misalignments, using both visual assessments and specialized tools.

Next, the shop facilitates a precise measurement of the existing frame and body components, comparing it against the dimensions of the new panel to guarantee a perfect fit. Prior to installation, the new panel undergoes its own quality checks for material integrity, surface smoothness, and proper painting or finishing. During the replacement process, skilled technicians adhere to strict protocol, utilizing appropriate tools and techniques to ensure secure bonding. Post-installation, a final inspection is conducted, verifying the alignment, fit, and overall aesthetic appeal of the repaired area, often comparing it against industry standards and customer expectations, much like how a master restorer might appraise a piece of art in a car scratch repair or auto detailing scenario.

Best Practices and Common Challenges in Achieving Top-Notch Panel Replacement Quality

Achieving top-notch quality in full panel replacement involves a blend of best practices and addressing common challenges unique to this process. Best practices include meticulous planning, utilizing high-quality materials, and strict adherence to manufacturer specifications. Every step from disassembly to installation requires precision to avoid misalignments or gaps that can compromise structural integrity and cosmetic appeal.

Common challenges in full panel replacement include dealing with damaged underlying components, ensuring proper fitment during car body restoration, and maintaining paint consistency through paintless dent repair techniques. Collision centers often face the hurdle of matching original factory finishes accurately. Adopting innovative technologies and relying on experienced technicians are crucial strategies to overcome these hurdles and deliver top-quality results in full panel replacements.

Shops employing meticulous quality control during full panel replacements ensure not just effective repairs but also customer satisfaction. By adhering to structured guidelines, addressing challenges proactively, and fostering a culture of excellence, businesses can maintain high standards in this specialized automotive service, enhancing their reputation and client trust.