Spot weld bonding repair is a specialized auto collision repair technique that uses pressure and heat to re-melt and fuse existing welds, enhancing structural integrity without compromising safety or quality. Skilled technicians employ resistance spot welding machines and mechanical presses to precisely apply these forces, restoring damaged vehicles to their pre-accident condition with superior structural repairs and long-lasting durability. Proper preparation, tailored welding parameters, and adequate cooling time are crucial for optimal results.

In the realm of automotive manufacturing, spot weld bonding repair is a critical process ensuring structural integrity. This article delves into the intricate role of pressure and heat in enhancing spot weld bonds, a game-changer for repairing and reinforcing joints. Understanding the basics of spot weld bonding repair is the first step towards mastering techniques that foster strong, lasting connections. By exploring effective strategies, professionals can navigate challenges, ensuring each repair is a testament to precision and durability, ultimately contributing to safer, more reliable vehicles.

- Understanding Spot Weld Bonding Repair: The Basics

- Pressure and Heat: Key Factors in Strengthening Bonds

- Techniques and Considerations for Effective Spot Weld Bonding Repair

Understanding Spot Weld Bonding Repair: The Basics

Spot weld bonding repair is a specialized technique used to fix weak or broken spot welds in metal components, which are commonly found in car damage repair and vehicle repair services. It involves applying precise amounts of pressure and heat to re-melt and fuse the existing weld, creating a stronger bond. This process is particularly crucial in collision repair services, where structural integrity must be restored without compromising safety or quality.

The basics revolve around understanding the science behind spot welds: metallic fusion and interdiffusion. By controlling temperature and pressure, technicians can recreate these processes, reinforcing the original weld joint. This method is not just a quick fix but offers a durable solution for both minor and major car damage repair scenarios, ensuring vehicles return to their structural best after collision repair services are completed.

Pressure and Heat: Key Factors in Strengthening Bonds

In the realm of spot weld bonding repair, pressure and heat are pivotal elements that significantly enhance the strength and integrity of bonds. When applying pressure during the welding process, it creates a robust connection between the materials by compacting them tightly together. This mechanical force ensures that there are minimal gaps or voids in the weld, which could compromise its structural soundness. Additionally, heat plays a crucial role by melting and intermingling the metal surfaces at the joint, forming a strong bond that rivals the parent material’s strength.

This combination of pressure and heat is particularly essential in auto collision repair, where precision and effectiveness are paramount. Collision centers often rely on skilled technicians to expertly apply these factors during spot weld bonding repair, ensuring that damaged vehicles are restored to their pre-accident condition. Car repair services benefitting from this method not only offer superior structural repairs but also guarantee long-lasting durability for the affected areas.

Techniques and Considerations for Effective Spot Weld Bonding Repair

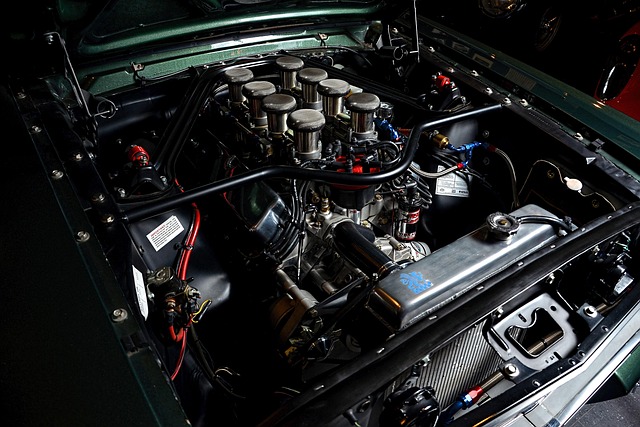

Effective spot weld bonding repair requires a precise application of pressure and heat. In the case of damaged or weakened welds, using specialized tools to apply controlled heat can re-melt and recrystallize the metal, restoring structural integrity. This process is often coupled with mechanical pressure to ensure proper joint formation and adhesion. For instance, in auto body services focusing on mercedes benz repair, technicians employ resistance spot welding machines that deliver precise current flow to generate heat, along with a mechanical press to apply uniform pressure, leading to robust repairs.

Body shop services specializing in spot weld bonding repair must consider several factors. Proper preparation of the weld area is crucial, involving cleaning and deburring to eliminate any contaminants or debris. The selection of appropriate welding parameters, including temperature, time, and pressure, depends on the specific metal types and joint design involved. Additionally, ensuring adequate cooling time prevents residual stress buildup, which could compromise the repair’s long-term durability.

In conclusion, the successful execution of spot weld bonding repair hinges on a precise balance of pressure and heat. By understanding these fundamental factors, technicians can effectively strengthen bonds, ensuring the structural integrity of various materials. Through the application of targeted techniques, this article has illuminated the path to achieving optimal results in spot weld bonding repair, thereby enhancing overall manufacturing efficiency.