OEM certified collision repair is paramount for auto repair shops aiming to provide top-tier bodywork services. This certification ensures that repairs, including dent repairs and frame straightening, adhere strictly to manufacturer specifications using original parts. Implementing real-time results and quality control measures, driven by advanced technologies like digital imaging and data analytics, achieves precision, speed, and transparency. Maintaining consistent quality through standardized procedures, rigorous technician training, high-quality materials, and robust feedback systems builds customer trust and preserves vehicle value.

In the realm of automotive repairs, maintaining exceptional quality is paramount, especially for Original Equipment Manufacturer (OEM) certified collision work. This article explores the significance of real-time results and robust quality control in ensuring top-tier OEM certified collision repair standards. We delve into implementing effective strategies, highlighting benefits, and sharing best practices to consistently deliver flawless repairs, fostering customer satisfaction and maintaining vehicle integrity.

- Understanding OEM Certified Collision Repair Standards

- Implementing Real-Time Results and Quality Control Measures

- Benefits and Best Practices for Consistent Quality in Repairs

Understanding OEM Certified Collision Repair Standards

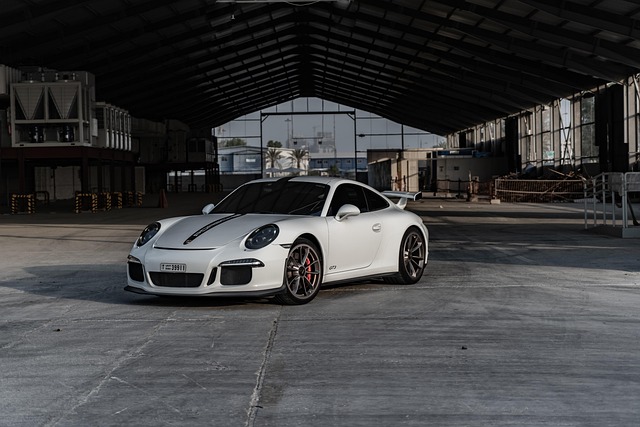

Understanding OEM Certified Collision Repair Standards is paramount for any auto repair shop aiming to deliver top-tier vehicle bodywork services. OEM, or Original Equipment Manufacturer, certification guarantees that a repair follows the exact specifications set by the car manufacturer. This involves not just fixing damages but also reinstating the vehicle’s original performance and aesthetics. In the case of car dent repairs, for instance, an OEM certified collision repair shop will use original factory parts, ensuring color matching perfection and structural integrity.

This rigorous standard extends to all aspects of vehicle bodywork, from frame straightening to panel replacement. It ensures that every repair is done with precision, utilizing advanced techniques and tools. For any customer looking for reliable and high-quality auto repair services, choosing a shop with OEM certification guarantees peace of mind, knowing their vehicle’s safety and value are in capable hands.

Implementing Real-Time Results and Quality Control Measures

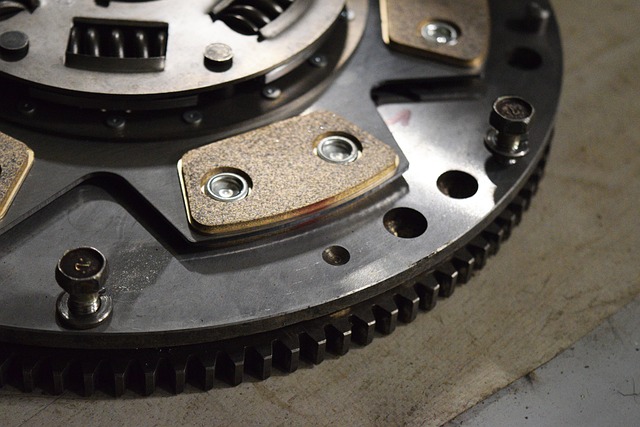

Implementing Real-Time Results and Quality Control Measures for OEM Certified Collision Repair is a strategic step to ensure top-notch service. Advanced technologies like digital imaging, 3D measurement systems, and real-time data analytics play a pivotal role in achieving precision and speed. These tools enable vehicle body shops to track each repair stage, from initial assessment to final inspection, providing an unparalleled level of transparency for clients.

Real-time results empower both the repair technicians and customers by allowing immediate feedback and adjustments during the bumper repair or any other collision repair process. Quality control measures, integrated into this system, guarantee that every OEM certified collision repair meets or exceeds industry standards. This ensures not just the safety but also the aesthetic appeal of the vehicle, making it a reliable choice for folks seeking top-quality repairs at certified shops.

Benefits and Best Practices for Consistent Quality in Repairs

Consistent quality in OEM certified collision repair is paramount to ensuring customer satisfaction and maintaining the vehicle’s original value. Implementing best practices enables auto body shops to deliver superior results, fostering trust among clients seeking expert auto body work, dent removal, or auto glass repair. One key benefit lies in standardized procedures, which minimize errors and ensure every repair meets or exceeds OEM specifications.

Best practices advocate for rigorous training and certification programs for technicians, keeping them abreast of the latest industry standards and advancements. Utilizing high-quality materials and state-of-the-art equipment is another critical aspect. Additionally, establishing a robust quality control system, involving regular inspections and customer feedback mechanisms, helps identify areas for improvement in both auto body work and repair processes.

OEM certified collision repair sets a new standard in the industry, ensuring high-quality, precise results. By implementing real-time results and quality control measures, repair shops can achieve consistent excellence. This approach not only benefits customers by providing top-tier repairs but also fosters trust and satisfaction. Adopting best practices reinforces the importance of meticulous standards, guaranteeing that every OEM certified collision repair meets or exceeds expectations.