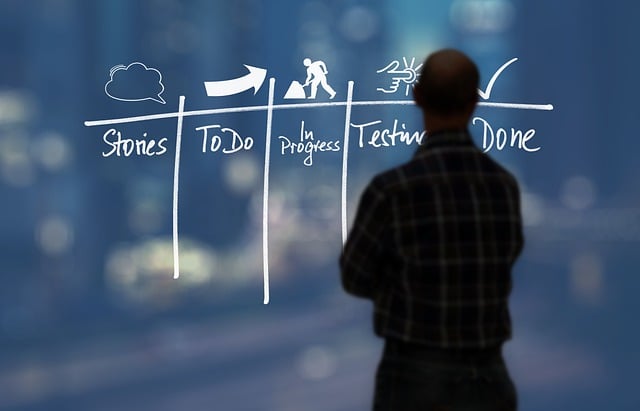

Certified welding techniques are essential for safety and quality in automotive industries, especially collision and dent repair. These methods ensure precise, consistent welds that minimize errors, defects, and hazards, enhancing worker and environmental safety. By adhering to strict standards, certified welders preserve painted surfaces, improve customer satisfaction, and reduce the need for re-repairs, ultimately fostering a high-quality car bodywork environment.

The importance of safety in welding industries cannot be overstated, given the inherent risks associated with the process. Certified welding techniques emerge as a game-changer, significantly mitigating risks and preventing accidents. This article delves into three key areas: how certified techniques enhance safety through risk reduction; their role in improving repair outcomes via professional training and case studies; and the necessity of continuous education to future-proof welding practices against evolving industry standards.

- The Impact of Certified Welding Techniques on Safety

- – Discussing the importance of safety in welding industries

- – How certified techniques contribute to risk mitigation and accident prevention

The Impact of Certified Welding Techniques on Safety

Certified welding techniques play a pivotal role in enhancing safety outcomes within the automotive industry, particularly in car body repair and auto repair services. These specialized methods are designed to ensure precision and consistency during the welding process, significantly reducing the risk of accidents and defects. By adhering to certified standards, vehicle body shops can create stronger, more durable bonds, minimizing the potential for structural failures that could compromise safety.

Moreover, certified welding techniques introduce best practices that protect both workers and the environment. Proper training in these methods equips technicians with the knowledge to handle hazardous materials safely and operate equipment correctly. This, in turn, fosters a culture of safety within auto repair services, leading to fewer injuries and environmental contamination. The implementation of certified welding practices is, therefore, not just about improving car body repair quality but also about upholding the highest standards of safety across the entire vehicle body shop operation.

– Discussing the importance of safety in welding industries

In the welding industry, safety is paramount. With certified welding techniques, professionals can navigate complex tasks while mitigating risks effectively. These techniques are designed to ensure the well-being of workers and the quality of the final product, making them a cornerstone of modern automotive repair, including bumper repair and car bodywork services.

Adhering to strict standards and employing specialized skills, certified welders reduce the potential for accidents and defects. This is especially crucial in sectors like paintless dent repair, where precision and integrity are key. By prioritizing safety through certification, the welding industry fosters an environment conducive to high-quality work, minimizing hazardous conditions and promoting efficient car bodywork services.

– How certified techniques contribute to risk mitigation and accident prevention

Certified welding techniques play a pivotal role in mitigating risks and preventing accidents within the industry. These specialized practices ensure that welds are performed with precision and adherence to strict safety standards, minimizing the potential for errors or defects that could lead to catastrophic failures. By employing certified methods, technicians can effectively manage hazards associated with welding processes, such as sparks, heat, and toxic fumes, which often pose significant risks in various work environments, including automotive collision repair and auto dent repair settings.

In the context of vehicle paint repair, for instance, precise and controlled welding is essential to preserve the integrity of the painted surface. Certified techniques ensure that welds are clean, strong, and aligned, preventing damage to the surrounding finish. This not only improves overall safety but also enhances the quality of repairs, ensuring customer satisfaction and reducing the need for costly re-repairs due to subpar welding practices.

In conclusion, adopting certified welding techniques is a game-changer for improving safety outcomes in the welding industry. By implementing these proven methods, companies can significantly reduce risks and prevent accidents, fostering a safer and more productive work environment. The impact of these techniques extends beyond individual welds, revolutionizing the overall workplace culture and ensuring the well-being of every employee.