Dimensional accuracy repair (DAR) is crucial in vehicle manufacturing and maintenance, ensuring structural integrity and safety through precise measurements and adjustments of component dimensions. Even minor deviations can cause alignment issues, poor fits, or reduced strength, making DAR essential for correcting visible damage and subtle misalignments. Skilled technicians use advanced techniques like 3D scanning and CAD technology to restore components to original dimensions, enhancing aesthetics, performance, and reliability while meeting regulatory standards.

In the automotive industry, maintaining exceptional dimensional accuracy repair is paramount for ensuring vehicle structural integrity. This meticulous process ensures every component aligns perfectly, from body panels to engine parts. Understanding dimensional accuracy in vehicle manufacturing involves recognizing that even minute errors can compromise safety and performance. This article delves into the significance of dimensional accuracy repair, exploring its impact on structural integrity and the advanced techniques employed to rectify deviations, ultimately fostering safer vehicles.

- Understanding Dimensional Accuracy in Vehicle Manufacturing

- The Impact of Dimensional Errors on Structural Integrity

- Repair Techniques for Ensuring Optimal Vehicle Structural Integrity

Understanding Dimensional Accuracy in Vehicle Manufacturing

In vehicle manufacturing, dimensional accuracy is a critical aspect ensuring structural integrity and overall quality. It refers to the precise measurement and control of various dimensions across different components, from body panels to chassis frames. Every part must adhere to stringent tolerances to guarantee optimal performance and safety. Even the slightest deviation can lead to issues like misalignment, poor fitting, or reduced strength in the final product.

Dimensional accuracy repair is a meticulous process aimed at addressing these discrepancies. It involves the use of advanced techniques and tools to measure, analyze, and adjust components back to their specified dimensions. This may include auto dent repair methods, such as paintless dent repair, where technicians skillfully manipulate panels without compromising their original shape or requiring extensive repainting at an auto collision center. By maintaining strict dimensional accuracy throughout manufacturing and employing these repair techniques, vehicle producers can uphold the structural integrity that is vital for both performance and passenger safety.

The Impact of Dimensional Errors on Structural Integrity

Dimensional errors in vehicle manufacturing or as a result of accidents can have severe implications for structural integrity. Even minor deviations in dimensions can lead to significant weaknesses and points of failure within the car body, compromising safety and durability. In a car body shop, skilled technicians employ dimensional accuracy repair techniques to address these issues. This meticulous process involves using specialized tools and knowledge to measure, adjust, and restore the original dimensions of affected components, ensuring they meet stringent industry standards.

Accurate dimensioning is crucial for maintaining the structural integrity of vehicles, particularly in areas like vehicle paint repair and auto body restoration. When dimensional errors go unchecked, they can result in misaligned panels, uneven surfaces, and compromised strength. By contrast, proper dimensional accuracy repair techniques not only enhance the overall aesthetics but also significantly improve the safety and reliability of the vehicle, ensuring it meets or exceeds regulatory requirements for structural integrity.

Repair Techniques for Ensuring Optimal Vehicle Structural Integrity

In the realm of vehicle structural integrity, Dimensional Accuracy Repair (DAR) stands as a game-changer, revolutionizing the way auto body work is performed. This advanced technique focuses on meticulous measurements and precise adjustments to ensure that every component of a vehicle’s structure aligns perfectly after repairs or modifications. DAR employs cutting-edge technology, such as 3D scanning and computer-aided design (CAD), to capture and analyze the exact dimensions of the vehicle before and during the repair process.

The effectiveness of DAR lies in its ability to correct not just visible damage but also subtle misalignments that might go unnoticed by the naked eye. By addressing these minutiae, body shop services can guarantee optimal structural integrity, enhancing safety and performance. This meticulous approach is particularly crucial for complex repairs or when customizing vehicles, ensuring that the car repair services rendered do not compromise the vehicle’s original design and stability.

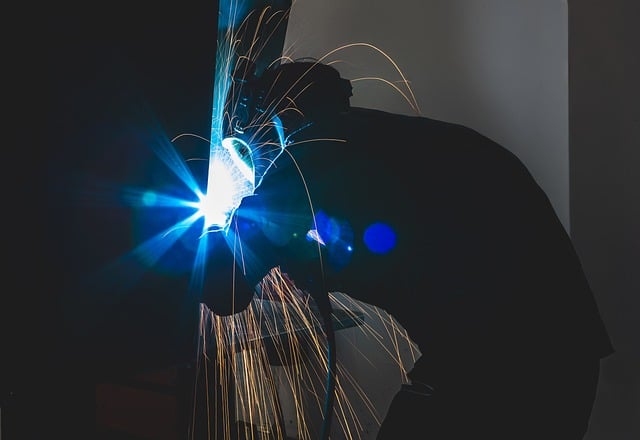

Dimensional accuracy repair is an indispensable process in vehicle manufacturing, ensuring structural integrity and overall quality. By meticulously addressing dimensional errors, manufacturers can prevent potential safety hazards and costly recalls. Through advanced repair techniques, such as precision grinding and laser calibration, even minute discrepancies are corrected, resulting in a robust and reliable vehicle structure. Investing in dimensional accuracy repair not only enhances the performance and longevity of vehicles but also builds trust among consumers who demand flawless craftsmanship.