Maintaining color matching excellence is vital for automotive service shops offering bumper repair or car restoration, as it preserves vehicle aesthetics and value. This process combines science and art, requiring skilled technicians to accurately match color codes considering variations in shade, gloss, and environmental conditions. Techniques like paintless dent repair offer non-invasive solutions achieving factory-like accuracy. Auto repair shops must implement rigorous quality control measures, including meticulous material selection, advanced color matching systems, regular staff training, and system calibration. Through continuous improvement and ongoing education, technicians develop superior craftsmanship in collision repair and custom finishes, ensuring precise color matching across diverse materials.

Shops strive for color matching excellence to meet customer expectations and stand out in a competitive market. This article explores the intricate process of achieving top-notch color accuracy, delving into the crucial role of quality control measures. We’ll uncover how businesses implement rigorous protocols, from initial sourcing to final inspection, ensuring consistent and precise color reproduction. Additionally, we’ll highlight continuous improvement strategies and training programs that contribute to maintaining high standards in the dynamic world of retail.

- Understanding the Importance of Color Matching Excellence

- Implementing Rigorous Quality Control Measures

- Continuous Improvement and Training for Optimal Results

Understanding the Importance of Color Matching Excellence

Maintaining color matching excellence is paramount for shops specializing in automotive services such as bumper repair or car restoration. In the world of vehicle aesthetics, achieving precise color coordination ensures that repairs and restorations seamlessly blend with the original finish, preserving the car’s overall look and value. This meticulous process goes beyond mere visual appeal; it significantly impacts customer satisfaction and the longevity of the vehicle’s appearance.

Color matching excellence involves a complex interplay of science and art. It requires skilled technicians to accurately assess and replicate color codes, taking into account factors like shade variations, gloss levels, and even environmental conditions. With techniques like paintless dent repair, shops can now offer non-invasive solutions that enhance color accuracy, ensuring results comparable to factory finishes. This level of precision not only meets but exceeds customer expectations in the competitive automotive service industry.

Implementing Rigorous Quality Control Measures

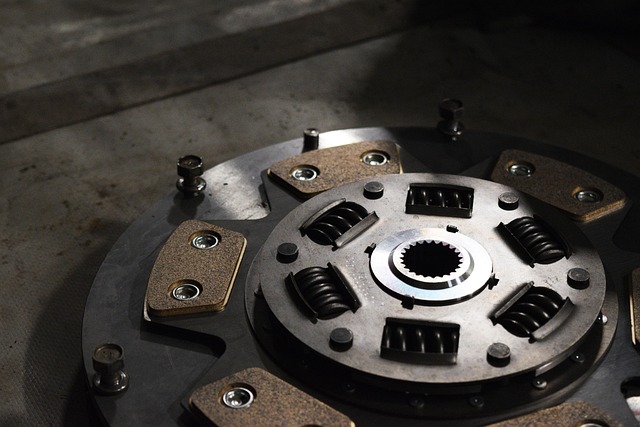

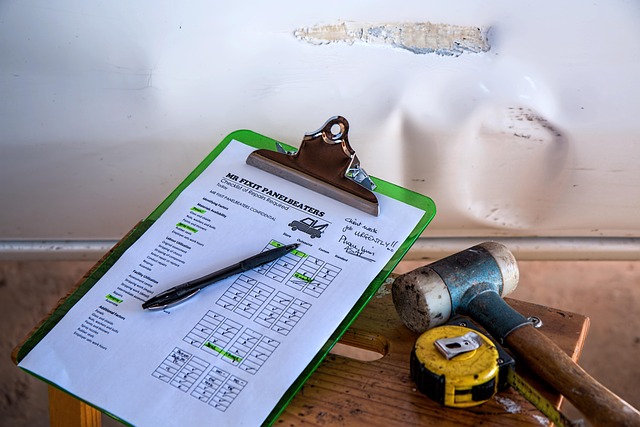

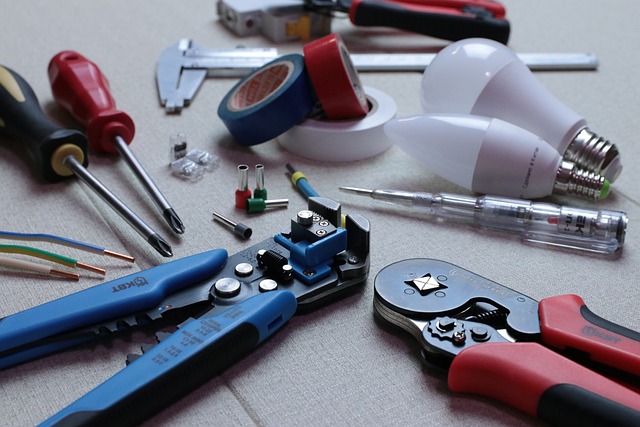

To achieve and maintain color matching excellence, shops must implement rigorous quality control measures at every stage of the repair process. This starts with meticulous material selection, ensuring that only top-grade paints and finishes are used for repairs. Each batch of paint is carefully tested to match the specific shade required, whether it’s for a classic car restoration or a modern Mercedes-Benz repair.

Advanced technology plays a pivotal role in this quality control. Shops utilize sophisticated color matching systems that scan and compare the original paint job with the replacement parts. This ensures precision in color accuracy, even for intricate details like car dent repair or paintless dent repair techniques. Regular staff training and calibration of these systems are also vital to guarantee consistent results over time.

Continuous Improvement and Training for Optimal Results

In the pursuit of color matching excellence, shops go beyond initial setup to foster a culture of continuous improvement. Regular training sessions for staff are integral to this process, ensuring that every team member is up-to-date with the latest techniques and technologies in auto glass repair and automotive body shop color matching. By investing in ongoing education, these facilities maintain high standards and deliver precise results, whether it’s for car collision repair or intricate custom finishes.

This commitment to training translates into consistent quality control measures. Technicians learn not just technical skills but also the art of meticulous observation, crucial for identifying subtle variations in color hues and shades. As a result, they become adept at matching colors across various materials, from auto glass to complex automotive body components, ultimately contributing to superior craftsmanship in their respective fields.

Shops that strive for color matching excellence must adopt a multi-faceted approach. By understanding the paramount importance of this aspect in retail, implementing robust quality control measures, and continuously improving processes through training, they can ensure consistent customer satisfaction. These strategies collectively contribute to achieving and maintaining the highest standards in color matching excellence.