Preventive maintenance is vital for frame machines in auto body work, saving time and money while ensuring equipment longevity and precision. Regular inspections, cleaning, and lubrication identify early issues, focusing on critical components like guides, bearings, and hydraulic systems. Best practices reduce costly repairs, enhance efficiency in tasks like bumper repair and dent removal, ultimately benefiting auto body shops.

Frame machines are integral to many industries, demanding consistent reliability. Preventive maintenance is key to ensuring optimal performance and longevity of these critical assets. This article delves into the essential practices for maintaining frame machine repairs, focusing on understanding their importance, identifying core components for regular inspection, and adopting best practices for efficient care. By implementing these tips, businesses can minimize downtime and maximize the lifespan of their frame machines.

- Understanding the Importance of Preventive Maintenance for Frame Machine Repair

- Key Components to Regularly Inspect and Maintain

- Best Practices for Efficient and Effective Preventive Care

Understanding the Importance of Preventive Maintenance for Frame Machine Repair

Preventive maintenance plays a pivotal role in ensuring the longevity and optimal performance of frame machines used in auto body work and car collision repair. By implementing regular care routines, technicians can significantly reduce the risk of unexpected breakdowns and costly repairs. This proactive approach is essential for maintaining the precision and efficiency of these critical machines, which are often the backbone of efficient car damage repair operations.

Regular preventive measures, such as cleaning, lubrication, and thorough inspections, help identify potential issues at an early stage. For instance, examining welds, checking for metal fatigue, and verifying the integrity of components can prevent minor problems from escalating into major disasters during the course of car collision repair or auto body work. This not only saves time and money in the long run but also guarantees that the frame machine remains aligned with industry standards and safety protocols.

Key Components to Regularly Inspect and Maintain

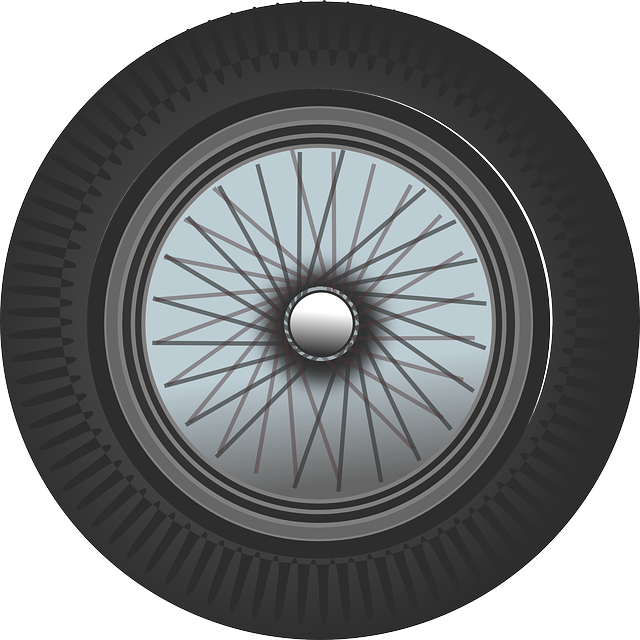

When it comes to frame machine repair, a proactive approach is essential for ensuring the longevity and reliability of your equipment. Regular inspection and maintenance are cornerstones of preventive care, allowing you to identify potential issues early on and avoid costly breakdowns. Key components that demand your attention include the rolling guides, bearings, and slides. These parts play a vital role in the smooth operation of the frame machine, as they facilitate the precise movement of the vehicle’s body during restoration or repair processes. Regular lubrication and cleaning are crucial to maintain their optimal performance, preventing wear and tear over time.

Additionally, inspecting the hydraulic system, including pumps, valves, and hoses, is paramount. Proper functionality of this system ensures controlled and efficient operation of the machine, which is critical in car restoration and vehicle bodywork tasks. Timely maintenance of these components can prevent leaks, reduce vibrations, and maintain consistent pressure levels, thereby enhancing the overall efficiency of your car repair services.

Best Practices for Efficient and Effective Preventive Care

Implementing best practices for preventive care is a game-changer when it comes to frame machine repair. Regular, thorough inspections are key; check for any signs of damage, corrosion, or misalignment, as these can often be early indicators of potential problems. Focus on critical areas such as joints, welds, and bolts, as these are common weak points in frame machines.

Effective preventive maintenance also involves staying proactive with cleaning and lubrication. Keep the machine’s components free from debris and dirt to prevent any obstructions or wear and tear. Regularly lubricate moving parts to ensure smooth operation and longevity, minimizing the risk of excessive friction and potential breakdowns. An auto body shop that prioritizes these practices can significantly reduce the need for costly repairs and enhance overall equipment efficiency, ultimately streamlining their bumper repair and dent removal processes.

Regular preventive maintenance is vital for keeping frame machines in top condition, ensuring their longevity and optimal performance. By following these essential practices, you can significantly reduce unexpected breakdowns, minimize downtime, and save on costly repairs. Implementing a structured maintenance routine not only benefits the equipment but also proves beneficial to your bottom line in the long run, making it an indispensable strategy for any operation involving frame machine repair.