Paintless Dent Repair (PDR) for steel panels is a cutting-edge, non-invasive auto body repair technique that preserves vehicles' original conditions and values by removing dents and scratches without traditional painting. This eco-friendly approach reduces material waste, makes it a sustainable and cost-effective solution for minor damage, and has gained significant popularity in the car repair services sector. Investing in PDR offers long-term advantages, including sustainability, cost savings, and environmental stewardship, setting businesses apart in a competitive market while appealing to environmentally conscious customers.

“PDR for steel panels is more than just a surface treatment—it’s an investment in durability, aesthetics, and sustainability. This article delves into the fundamentals of PDR (Polished Metal Deposit) coating for steel panels, highlighting its numerous advantages as a long-term solution. We explore how this technology enhances structural integrity, reduces maintenance costs, and contributes to eco-friendly practices. By understanding these benefits, you’ll grasp why PDR-treated steel panels are a smart choice for enduring value.”

- Understanding PDR for Steel Panels: The Basics

- Benefits of Investing in PDR-Treated Steel Panels

- Long-Term Value and Sustainability Considerations

Understanding PDR for Steel Panels: The Basics

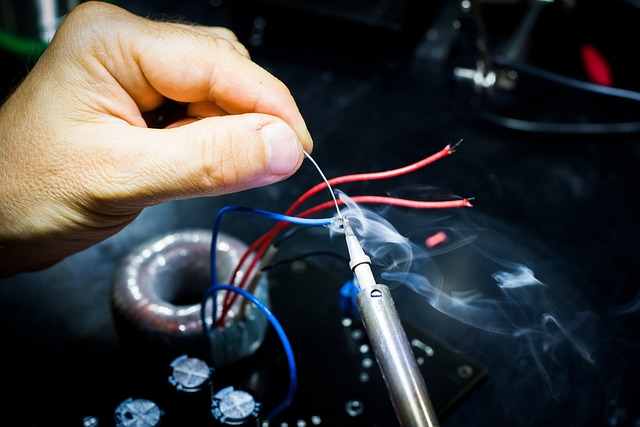

PDR for steel panels, or Paintless Dent Repair, is a cutting-edge technique revolutionizing the auto body services industry. It’s a non-invasive method that allows professionals to remove dents and scratches from vehicle surfaces without traditional painting or auto body repair methods. This process has gained significant traction as a cost-effective and efficient solution for car repair services, particularly for minor damage. By utilizing specialized tools and trained techniques, PDR experts can restore panels to their original condition, almost like new.

The appeal of PDR extends beyond its ability to preserve the value of vehicles. It’s also an eco-friendly approach, eliminating the need for additional paint and materials often required in conventional auto painting methods. This makes it a sustainable choice for those seeking long-term investment options in vehicle maintenance. With the right training and equipment, PDR can be a lucrative skill within the car repair services sector, enabling businesses to offer high-quality, efficient, and environmentally conscious solutions to their clients.

Benefits of Investing in PDR-Treated Steel Panels

Investing in PDR-treated steel panels offers a multitude of long-term benefits for both businesses and individuals in the automotive industry. The process, known as PDR (Paintless Dent Repair), revolutionizes car bodywork maintenance by mitigating damage to steel panels without the need for extensive collision center services or costly fender repair procedures. This non-intrusive method preserves the original finish, ensuring that vehicles maintain their aesthetic value and resale potential.

Moreover, opting for PDR for steel panels contributes to sustainability efforts. By minimizing the demand for replacement parts and reducing waste from traditional fender repair, this innovative technique aligns with the growing trend of eco-friendly car care solutions. In today’s competitive market, prioritizing long-term savings while fostering environmental stewardship can set businesses apart and attract environmentally conscious customers seeking efficient and effective vehicle upkeep options.

Long-Term Value and Sustainability Considerations

Investing in PDR for steel panels offers long-term value and sustainability benefits that go beyond immediate cost savings. This eco-friendly approach to auto body restoration and vehicle bodywork repair not only preserves the life of an already manufactured product but also reduces waste and minimizes environmental impact, aligning with a growing trend towards sustainable practices in all industries.

Consider the broader implications: by choosing PDR over traditional auto body replacement for car damage repair, you’re contributing to a circular economy where materials are reused and recycled, lowering dependency on resource-intensive manufacturing processes. This long-term perspective positions PDR as not only an economical solution for steel panel repairs but also a responsible choice that benefits both consumers and the planet.

PDR (Polished Diffused Reflective) treatment for steel panels presents a compelling long-term investment opportunity. By enhancing aesthetics, durability, and reflectivity, PDR-treated steel panels offer significant advantages over conventional counterparts. Their increased value retention, reduced maintenance costs, and environmental sustainability make them a sound choice for investors. As the demand for energy-efficient and visually appealing building materials grows, investing in PDR for steel panels is not just a smart decision but also a forward-thinking one.