Specialty collision hardware is a tailored solution for auto body repair, using advanced materials and precise engineering to match original manufacturer standards. Essential for complex bodywork services, these custom components address unique challenges with intricate shapes and specialized vehicle models, ensuring flawless restoration. Over standard repair parts, specialty hardware offers superior fitment, aesthetics, and durability, leading to reduced future repairs and cost savings. Choosing the right specialty collision hardware, compatible with vehicle specifications and made from high-quality materials, is key for successful and durable auto body repairs.

In the realm of collision repair, differentiating between standard parts and specialty hardware is paramount. Specialty collision hardware, designed for specific vehicle makes and models, offers distinct advantages over generic alternatives. This article explores the definition, features, and benefits of specialty hardware while guiding you through considerations for selection. By understanding these nuances, collision centers can enhance their repairs, ensure precision, and deliver superior customer satisfaction.

- Understanding Specialty Collision Hardware: Definition and Features

- Advantages of Using Specialty Hardware Over Standard Parts

- Considerations and Best Practices for Choosing the Right Collision Repair Components

Understanding Specialty Collision Hardware: Definition and Features

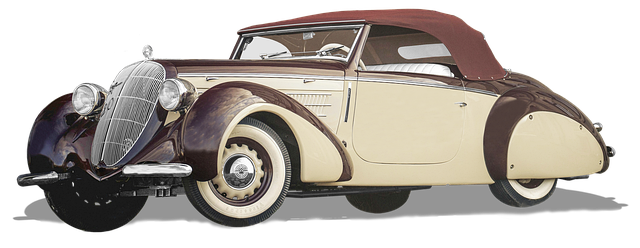

Specialty collision hardware refers to specialized components designed specifically for repairing and restoring vehicle bodywork. These parts are distinct from standard repair parts in their level of customization and precision engineering, tailored to address unique challenges encountered during auto body shop repairs. Features that define specialty collision hardware include advanced materials, precise manufacturing tolerances, and innovative designs intended to match the original car manufacturer’s specifications exactly.

Unlike generic auto body shop replacements, these hardware pieces are often required for complex car bodywork services involving intricate shapes, tight spaces, or specialized vehicle models. They can be as simple as a single panel or as complex as complete sub-assemblies, ensuring that every detail of the vehicle’s original structure and aesthetics is preserved. This level of customization plays a crucial role in achieving flawless results during vehicle bodywork repairs.

Advantages of Using Specialty Hardware Over Standard Parts

Using specialty collision hardware offers several advantages over standard repair parts for vehicle repair and auto body work. One of the key benefits is precision and fit; specialty hardware is often designed to exacting standards, ensuring it seamlessly integrates into specific models and makes, reducing the risk of misalignment or poor fitment commonly associated with generic parts. This precision translates to better aesthetics in the final product, which is paramount for body shop services aiming to deliver high-quality auto body work.

Additionally, specialty collision hardware can enhance durability and longevity in repairs. These specialized components are typically crafted from superior materials and built to withstand the rigors of collision events, offering greater strength and resilience compared to standard parts. This increased durability not only contributes to safer vehicle operation but also reduces the frequency of future repairs, ultimately saving time and money for both body shop services providers and vehicle owners in the long run.

Considerations and Best Practices for Choosing the Right Collision Repair Components

When selecting components for collision repair, understanding the distinct needs of specialty collision hardware is paramount. Unlike standard repair parts, which cater to general auto bodywork and car paint repair, specialty hardware addresses unique challenges arising from complex repairs or specific vehicle types. For instance, in cases involving intricate auto bodywork or specialized paints, choosing the right hardware can significantly impact the outcome of the repair process.

Best practices for selecting collision repair components include meticulous consideration of vehicle specifications, ensuring compatibility with both the make and model. Additionally, prioritizing high-quality materials is crucial for longevity and performance. Reputable suppliers often offer a range of options, allowing professionals in automotive repair to choose based on their skill level and project requirements. Ultimately, staying informed about industry trends and advancements in specialty collision hardware will enable auto bodyworkers to provide top-tier repairs.

When it comes to collision repair, opting for specialty hardware offers significant advantages over standard parts. Its tailored design and advanced features ensure superior performance and longer-lasting results. However, careful consideration is key. By understanding your vehicle’s specific needs and following best practices, you can choose the right specialty collision hardware, enhancing the quality and efficiency of your repair process. Embrace these components to elevate your repair standards and satisfy customers seeking top-tier workmanship.