Induction heating repair is a specialized process critical for maintaining industrial and automotive applications, such as car paint repair and vehicle restoration. It involves fixing or replacing faulty induction heaters that use electromagnetic fields to generate heat in conductive materials for tasks like metal melting, welding, and heat treatment. Common issues include cracked coils, loose connections causing short circuits, and sensor failures leading to temperature control malfunctions. Effective troubleshooting requires structured approaches combining technical expertise with strategic planning, utilizing advanced diagnostic tools to identify root causes. Repairs demand adherence to safety protocols, proper grounding, and the use of genuine parts for long-lasting solutions, especially in precision applications like vehicle body shops.

Induction heating systems, integral to various industrial processes, demand meticulous care and repair. This article demystifies the key elements of induction heating repair, equipping you with essential knowledge for effective maintenance. From understanding the basic principles to identifying common issues and implementing successful strategies, each step is crucial in ensuring optimal system performance. Master these aspects, and you’ll be well-equipped to tackle induction heating repairs head-on, minimising downtime and maximising efficiency.

- Understanding Induction Heating Repair: The Basics

- Identifying Common Issues and Their Causes

- Effective Strategies for Successful Induction Heating Repair

Understanding Induction Heating Repair: The Basics

Induction heating repair is a specialized process that involves fixing or replacing faulty induction heaters, which are crucial components in various industrial applications and automotive processes like car paint repair and vehicle restoration at an automotive body shop. Understanding this repair process begins with grasping the fundamentals of induction heating technology. Induction heating utilizes electromagnetic fields to generate heat within conductive materials, making it a versatile method for tasks such as metal melting, welding, and heat treatment.

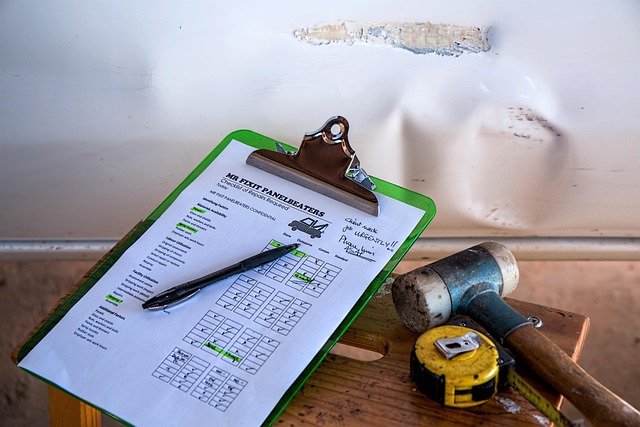

When an induction heater fails or requires maintenance, professionals must assess the issue, which could range from faulty coils and power supplies to misaligned components. The repair process involves careful disassembly, inspection, and replacement of defective parts while ensuring proper grounding and safety protocols are followed. Proficient technicians might also employ advanced diagnostic tools to pinpoint problems, thereby enhancing the efficiency and effectiveness of the induction heating repair, ultimately contributing to smoother operations in automotive body shops and industrial settings alike.

Identifying Common Issues and Their Causes

When it comes to induction heating repair, identifying common issues is the first step towards effective troubleshooting. Many problems arise from simple wear and tear, especially in industrial settings where machines operate continuously. Over time, components may show signs of damage, such as cracked coils or faulty wiring, requiring immediate attention for seamless induction heating operation.

Specific issues can include short circuits due to loose connections, temperature control malfunctions caused by sensor failures, or even bumper repair needs when parts become misaligned. In the context of automotive applications, paint-related problems are common; a faulty paint job or damage during auto painting processes can disrupt the heating process. Thankfully, techniques like paintless dent repair offer non-invasive solutions for minor cosmetic issues, ensuring efficient repairs without extensive disruption to the system.

Effective Strategies for Successful Induction Heating Repair

Successful induction heating repair requires a systematic approach that combines technical expertise with strategic planning. First, thorough inspection is key; assess the damaged area, identifying the extent and nature of the issue. This step is crucial in determining the most effective repair method. Once inspected, use advanced diagnostic tools to pinpoint the exact cause, whether it’s a faulty coil, damaged copper windings, or a misaligned magnet.

Next, employ specialized techniques tailored to induction heating systems. This might involve replacing components, retuning coils, or recalibrating sensors. For instance, in a vehicle body shop, induction heating is often used for metal welding and repair; ensuring precise control during the repair process can yield excellent results for vehicle restoration and dent repair. Remember, adherence to safety protocols and using genuine replacement parts are essential to guarantee long-lasting repairs.

Induction heating repair is a specialized process that demands a deep understanding of its key elements. By identifying common issues, their causes, and implementing effective strategies, professionals can ensure precise and efficient repairs. Remember, timely maintenance and expert intervention are crucial to keeping induction heating systems running smoothly, ultimately enhancing overall performance and longevity.