Mercedes' advanced monocoque unibody construction offers precision and quality but can be vulnerable to extreme weather, mishandling, or accidents, leading to common issues like metal cracks and weakened welds. Reputable body shops specializing in Mercedes unibody repair use advanced equipment for precise measurements and post-repair structural scanning, ensuring accurate damage assessment and meticulous repairs that maintain vehicle safety and performance. This process identifies even minor discrepancies, guides auto body painting and dent repair, and guarantees a structurally sound final product. Implementing advanced scanning technologies enhances both quality and efficiency in Mercedes unibody repair, with best practices including regular calibration, technician training, and integrating scanning into the repair workflow from the start to reduce issue oversight.

Mercedes unibody construction, known for its precision and strength, requires meticulous care during repairs. With advanced scanning technologies like 3D laser scanning, post-repair structural integrity can be accurately assessed. This article delves into the intricacies of Mercedes unibody repair, focusing on why post-repair structural scanning is essential. We explore the vulnerabilities unique to these vehicles and how modern scanning methods ensure superior quality, precision, and long-term performance in Mercedes unibody repairs.

- Understanding Mercedes Unibody Construction and Its Vulnerabilities

- The Role of Post-Repair Structural Scanning in Ensuring Quality

- Benefits and Best Practices for Implementing Advanced Scanning Technologies

Understanding Mercedes Unibody Construction and Its Vulnerabilities

Mercedes unibody construction is renowned for its precision and quality, employing advanced materials to ensure structural integrity. The unibody design, a monocoque structure, fuses the car’s frame and body panels into a single unit, significantly enhancing rigidity and passenger safety. However, this intricate system isn’t without vulnerabilities. Extreme weather conditions, improper handling, or accidents can introduce stress points that compromise the unibody’s structural integrity. Cracks in the metal, misaligned panels, or weakened welds are common issues requiring expert attention.

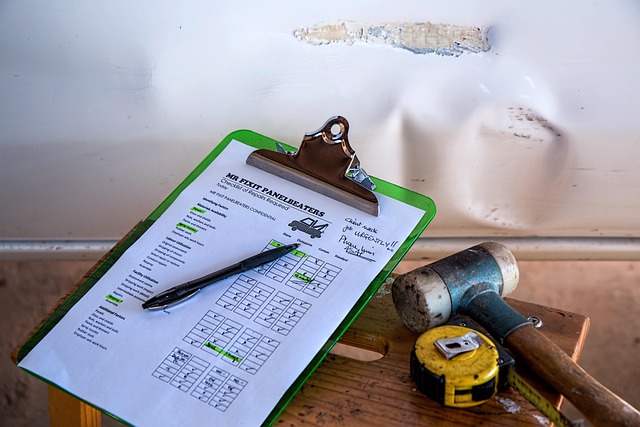

Mercedes unibody repair demands a meticulous approach to preserve the car’s original strength and aesthetics. Reputable body shops offering advanced auto body restoration services employ specialized equipment for precise measurements and post-repair structural scanning. This ensures that any damage is accurately assessed and repairs executed with precision, maintaining the vehicle’s overall safety and performance, much like restoring a car dent repair to its former flawless state.

The Role of Post-Repair Structural Scanning in Ensuring Quality

Post-repair structural scanning plays a pivotal role in ensuring the highest quality standards during Mercedes unibody repair. By employing advanced technology to meticulously examine the vehicle’s framework, technicians can identify even the subtlest discrepancies or unevenness that may have gone unnoticed during initial repairs. This meticulous process involves using specialized tools to capture detailed images and data of the repaired area, allowing for a comprehensive analysis of structural integrity.

The benefits extend beyond simply identifying issues; post-repair scanning facilitates precise adjustments and refinements in auto body painting and vehicle dent repair processes. For instance, if paintless dent repair techniques were employed, the scanner can verify the success of the process by checking for any residual imperfections or misalignments. This ensures that the final product not only looks flawless but also maintains the structural integrity required to withstand the rigors of daily driving, enhancing safety and reliability for Mercedes owners.

Benefits and Best Practices for Implementing Advanced Scanning Technologies

Implementing advanced scanning technologies in Mercedes unibody repair offers numerous benefits that elevate the quality and efficiency of auto body restoration. These tools enable precise measurements and analysis, allowing technicians to accurately assess damage, especially in complex cases like bumper repair or dent removal. By providing detailed digital models, scanners help identify subtle structural variations, ensuring every component is restored to its original specifications.

Best practices for utilizing these technologies include regular calibration and maintenance to guarantee accurate readings. Technicians should be trained on the software to interpret scans effectively. Additionally, integrating scanning into the repair process from the outset facilitates better workflow management and reduces the risk of overlooking potential issues. This comprehensive approach ensures not just visually appealing Mercedes unibody repairs but also structurally sound ones.

Mercedes unibody repair, given its complex construction and potential vulnerabilities, requires meticulous attention. Post-repair structural scanning plays a pivotal role in ensuring the quality and integrity of these vehicles. By employing advanced scanning technologies, repair shops can achieve precise measurements, detect minute anomalies, and guarantee that each component aligns perfectly with Mercedes’ stringent standards. This process not only enhances the safety and performance of the vehicle but also ensures customer satisfaction for years to come.