Mercedes carbon fiber parts, known for their strength and durability, require specialized repair due to their unique properties. Professional body shops employ skilled technicians who assess damage, use advanced techniques like composite patching or lamination, and ensure structural integrity and aesthetic quality through precise matching of original specifications. Proper repair methods restore both performance and visual appeal, ensuring Mercedes carbon fiber parts function as effectively as new on the road.

Mercedes-Benz has long been an innovator in automotive materials, and carbon fiber is a key component in their modern vehicles. However, like any material, it’s not immune to damage. This article explores whether repaired Mercedes carbon fiber parts can retain their strength. We’ll delve into the unique properties of these components, the repair process using advanced techniques, and how to evaluate the restored strength and durability of these high-tech pieces, focusing on effective Mercedes carbon fiber parts repair.

- Understanding Mercedes Carbon Fiber Parts and Their Properties

- The Repair Process: Techniques and Considerations

- Evaluating the Strength and Durability of Repaired Carbon Fiber Components

Understanding Mercedes Carbon Fiber Parts and Their Properties

Mercedes carbon fiber parts are known for their lightweight yet incredibly strong construction—a key reason they’re favored in high-performance vehicles like Mercedes models. This advanced material combines the best properties of traditional fibers with a unique resin matrix, resulting in exceptional stiffness and durability. Carbon fiber is not only lighter than metal, but it also offers superior resistance to corrosion and fatigue.

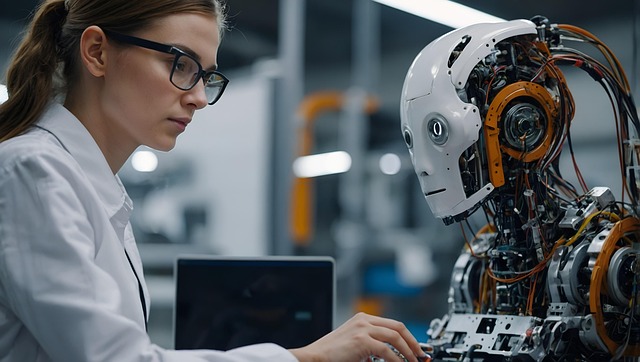

Understanding how these parts can be repaired is crucial for vehicle owners. Repairs often involve matching the original part’s specifications precisely, as carbon fiber’s unique properties must be preserved to maintain structural integrity. Professional body shop services specializing in auto dent repair and car damage repair employ skilled technicians who use advanced techniques and materials to ensure repairs are both effective and discreet. These experts can assess the extent of the damage and determine if a successful repair is feasible, preserving the vehicle’s performance and aesthetics.

The Repair Process: Techniques and Considerations

The repair process for Mercedes carbon fiber parts involves a meticulous approach to ensure the retention of strength and structural integrity. Skilled technicians utilize advanced techniques tailored to this unique material, as carbon fiber is known for its lightweight yet robust properties. The first step is to carefully assess the damage, which can range from small cracks to significant breaks. Depending on the extent of the damage, repair methods may include composite patching, where specialized resins and fibers are used to fill and strengthen the affected area.

After the damaged section is prepared, experienced mechanics employ techniques such as layering fresh carbon fiber sheets or pre-pregnated materials over the repair site, ensuring precise alignment and minimal overlap. This process often involves precision cutting and shaping to create a seamless fusion with the surrounding vehicle bodywork. Once the layers are in place, they’re cured under controlled conditions, allowing the composite material to achieve its maximum strength. Proper curing is crucial for ensuring the long-term performance of these repairs, especially considering the high standards expected from Mercedes vehicles.

Evaluating the Strength and Durability of Repaired Carbon Fiber Components

When evaluating the strength and durability of repaired Mercedes carbon fiber components, it’s crucial to consider both structural integrity and aesthetic quality. Repairs on these advanced automotive materials require skilled technicians using specialized techniques like composite bonding or structural lamination. The success of these repairs lies in matching the original material properties, ensuring seamless integration with the existing vehicle structure.

Proper repair methods can significantly restore the structural capabilities of carbon fiber parts, rivaling those of new components. However, factors such as the extent of damage, quality of materials used in repairs, and adherence to best practices in automotive repair play pivotal roles. Unlike traditional metal body panels, which often require extensive welding or replacement, car paint services for carbon fiber repairs can be more precise, preserving the material’s inherent strength while enhancing its visual appeal through meticulous finishing and color matching. Effective vehicle body repair techniques ensure that repaired Mercedes carbon fiber parts not only look like new but also perform as such on the road.

Mercedes carbon fiber parts, known for their strength and lightweight properties, can effectively retain their structural integrity after repair. The key lies in understanding the material’s unique characteristics and employing precise repair techniques. By carefully evaluating and addressing potential weaknesses, repaired components can match or even surpass the original strength, ensuring the safety and performance of Mercedes vehicles equipped with these innovative parts. This conclusion highlights the viability of carbon fiber part repairs, positioning it as a viable solution for extending the lifespan of these advanced automotive materials.