TL;DR: Adhering to Original Equipment Manufacturer (OEM) guidelines is essential for effective bumper crack repair, ensuring structural integrity, aesthetic appeal, and safety. These guidelines provide specific material properties, joint strength, and precision measurements compatible with your vehicle's design. Following OEM procedures, including approved materials, techniques, and precise measurements, auto body services can achieve long-lasting, seamless repairs, particularly for luxury vehicles like Mercedes Benz. Deviating from these standards may compromise effectiveness and pose safety risks. A comprehensive bumper crack repair process includes thorough inspection, cleaning, using OEM-recommended fillers and sanders, applying primer and base coat for optimal adhesion in auto bodywork.

Bumper crack repair is crucial for maintaining vehicle aesthetics and safety. However, navigating this process requires adhering to Original Equipment Manufacturer (OEM) guidelines to ensure quality and longevity. This article delves into understanding OEM repair standards and why they are essential. We provide a step-by-step guide to help you ensure that every bumper crack repair follows these critical guidelines, ultimately enhancing vehicle performance and preserving its value.

- Understanding Bumper Crack Repair Standards

- The Importance of Following OEM Guidelines

- Step-by-Step Guide to Ensuring Quality Repairs

Understanding Bumper Crack Repair Standards

When it comes to bumper crack repair, adhering to Original Equipment Manufacturer (OEM) guidelines is paramount. These standards ensure that the repair not only looks like new but also maintains structural integrity and safety. OEM repair procedures are meticulously designed, taking into account material properties, joint strength, and aesthetic precision. Deviating from these guidelines can compromise the overall quality of the repair, affecting both performance and appearance.

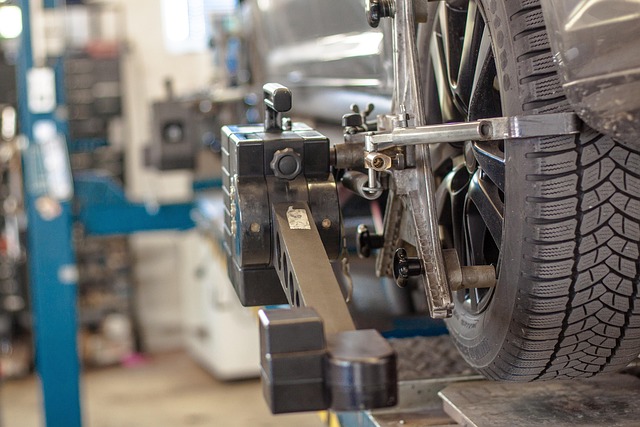

Understanding these standards involves recognizing the importance of using approved materials, following specific techniques, and adhering to precise measurements. For instance, tire services often require specialized knowledge to ensure proper alignment and balance after bumper crack repair. Similarly, Mercedes Benz repair, or any luxury auto maintenance for that matter, demands a deep understanding of intricate design details and precision engineering. By strictly conforming to OEM guidelines, repair technicians can guarantee not just the functionality but also the longevity of the vehicle’s exterior.

The Importance of Following OEM Guidelines

Following Original Equipment Manufacturer (OEM) guidelines for bumper crack repair is paramount to ensuring structural integrity and aesthetic appeal. OEM specifications are meticulously crafted based on extensive research and testing, guaranteeing compatibility with your vehicle’s design and safety standards. Deviating from these guidelines can compromise the effectiveness of the repair, leading to potential safety risks and reduced longevity of the bumper.

Adhering to OEM directives ensures that every step of the repair process—from material selection to application techniques—is performed optimally. This meticulous approach is crucial for aligning the repaired area seamlessly with the rest of the vehicle’s paneling, preserving the overall aesthetic of your vehicle. Moreover, relying on auto body services that prioritize OEM guidelines can prevent future issues, as they understand the intricate details and nuances specific to each vehicle model, including essential tire services considerations.

Step-by-Step Guide to Ensuring Quality Repairs

Ensuring quality repairs for bumper crack repair is paramount to maintaining your vehicle’s aesthetics and safety standards. Here’s a step-by-step guide to achieve this, focusing on both efficiency and durability. Start by thoroughly inspecting the damaged area, identifying the extent of the crack or dent. Next, prepare the surface by cleaning it to remove any dirt, grease, or debris that could compromise the bond strength. This involves using specialized cleaners and degreasers suitable for automotive repair.

Proceed with applying the appropriate auto body shop techniques and materials. This includes using OEM (Original Equipment Manufacturer) guidelines for filler selection, application, and curing times. For instance, use a high-quality, crack-resisting filler compatible with your vehicle’s bodywork. After carefully filling the crack, sand down the surface to achieve a smooth finish. Repeat this process if necessary until the bumper looks uniform with the surrounding panel. Finally, apply a primer and then a base coat to ensure proper adhesion for any additional painting or coating required in auto bodywork.

When undertaking bumper crack repair, adhering to Original Equipment Manufacturer (OEM) guidelines is paramount. These standards ensure not only the structural integrity of your vehicle but also maintain its aesthetic appeal. By following a step-by-step approach that incorporates OEM best practices, you can guarantee quality repairs that meet or exceed industry benchmarks for bumper crack repair.