The compatibility of auto body shop parts is paramount for achieving quality repairs, maintaining structural integrity, and optimizing vehicle performance. Top-tier shops invest in diverse, high-quality inventories meticulously matched with various makes and models to handle a wide range of collision repair needs, from minor dents to complex damage. Accurately identifying vehicle make, model, and year is crucial for compatibility. Environmental factors can impact older vehicles' bodywork, requiring specialized parts. Tailored replacement parts like auto glass repair or new bodywork ensure precise fit and structural integrity for complete car body restoration. Prioritizing parts compatibility enhances customer satisfaction, speeds up repairs, reduces downtime, and minimizes costs, making it a key strategy for successful auto body shops in a competitive market.

In the realm of auto repair, compatibility of parts is a vital cornerstone for achieving quality outcomes. When an auto body shop sources replacement parts, ensuring they seamlessly fit and function with existing components is crucial. This article delves into the significance of compatibility in auto body shop parts, exploring key factors influencing it and the substantial benefits of prioritizing this aspect. Understanding these dynamics fosters superior repair work and enhances customer satisfaction.

- Understanding Compatibility: The Foundation of Quality Repairs

- Key Factors Affecting Auto Body Shop Parts Compatibility

- Benefits of Prioritizing Parts Compatibility in Auto Body Shops

Understanding Compatibility: The Foundation of Quality Repairs

Understanding compatibility is the foundation for delivering quality repairs at an auto body shop. When it comes to auto body shop parts, ensuring each component is compatible with the specific vehicle model and year is paramount. Using the right parts guarantees that the repair not only looks pristine but also functions optimally. Inaccurate or incompatible parts can lead to structural weaknesses, compromising the safety and durability of the vehicle.

Auto body shops offering top-notch collision repair services understand this crucial aspect. They invest in a diverse inventory of high-quality auto body shop parts, meticulously matching them with various makes and models. This way, they can accommodate a wide range of car body restoration needs, from dent removal to more complex repairs. The result is a vehicle that not only returns to its pre-accident condition but does so reliably and securely.

Key Factors Affecting Auto Body Shop Parts Compatibility

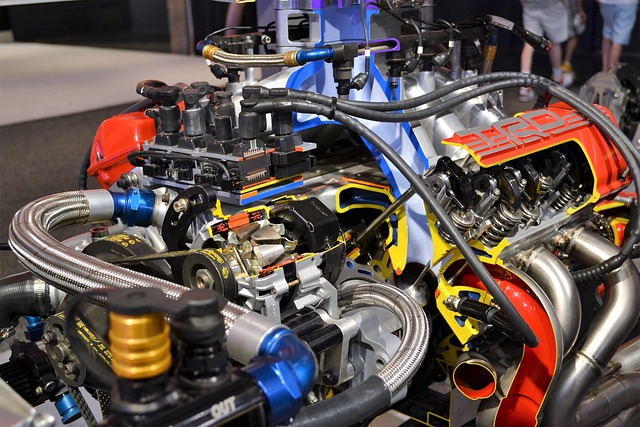

When ensuring compatibility with auto body shop parts, several key factors come into play. One of the primary considerations is the specific make and model of the vehicle in question. Every car manufacturer has unique design specifications, and even within a particular brand, different years or models may have slight variations in their auto body shop parts. For instance, a 2015 Toyota Camry might require distinct fender panels or door shells compared to a 2018 model. Therefore, accurate identification of the vehicle’s make, model, and year is essential before sourcing replacement parts.

Another critical factor affecting compatibility is the condition and age of the existing auto body shop parts on the car. Car bodywork, including panels, frames, and components, can deteriorate over time due to various environmental factors like rust, corrosion, or exposure to harsh weather conditions. Older vehicles might require specialized attention as their parts may not be readily available or compatible with newer models. In cases where a complete car body restoration is necessary, ensuring that replacement parts, such as auto glass repair or new bodywork, are specifically tailored to the vehicle’s original specifications becomes paramount for a seamless fit and structural integrity.

Benefits of Prioritizing Parts Compatibility in Auto Body Shops

Prioritizing parts compatibility in an auto body shop is paramount for several reasons. It ensures that all components, from frames to trim pieces, seamlessly integrate, leading to higher-quality repairs and a more aesthetically pleasing finish. This attention to detail not only enhances the overall appearance of the vehicle but also boosts customer satisfaction.

Moreover, compatible parts contribute to the efficiency of the repair process. When parts fit perfectly, technicians can work faster and with fewer delays, minimizing downtime for the vehicle owner. This is especially crucial in today’s fast-paced automotive industry where quick turnaround times are expected. Additionally, using compatible parts often translates to more affordable repairs, as substandard or incompatible parts can lead to costly replacements or additional labor costs during installation.

Ensuring compatibility with auto body shop parts is paramount for achieving high-quality repairs. By understanding the key factors affecting compatibility and prioritizing it, auto body shops can offer customers durable, reliable, and aesthetic replacements. This not only enhances customer satisfaction but also contributes to the overall safety and longevity of vehicles on the road.